A kind of domestic garbage flash mineralization treatment method

A technology for mineralization treatment and domestic waste, applied in the combustion method, incinerator, combustion type, etc., can solve the problems of difficult slag production operation, discount of production and processing capacity, and high technical content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] A method for treating domestic waste with flash mineralization, the method comprising the steps of:

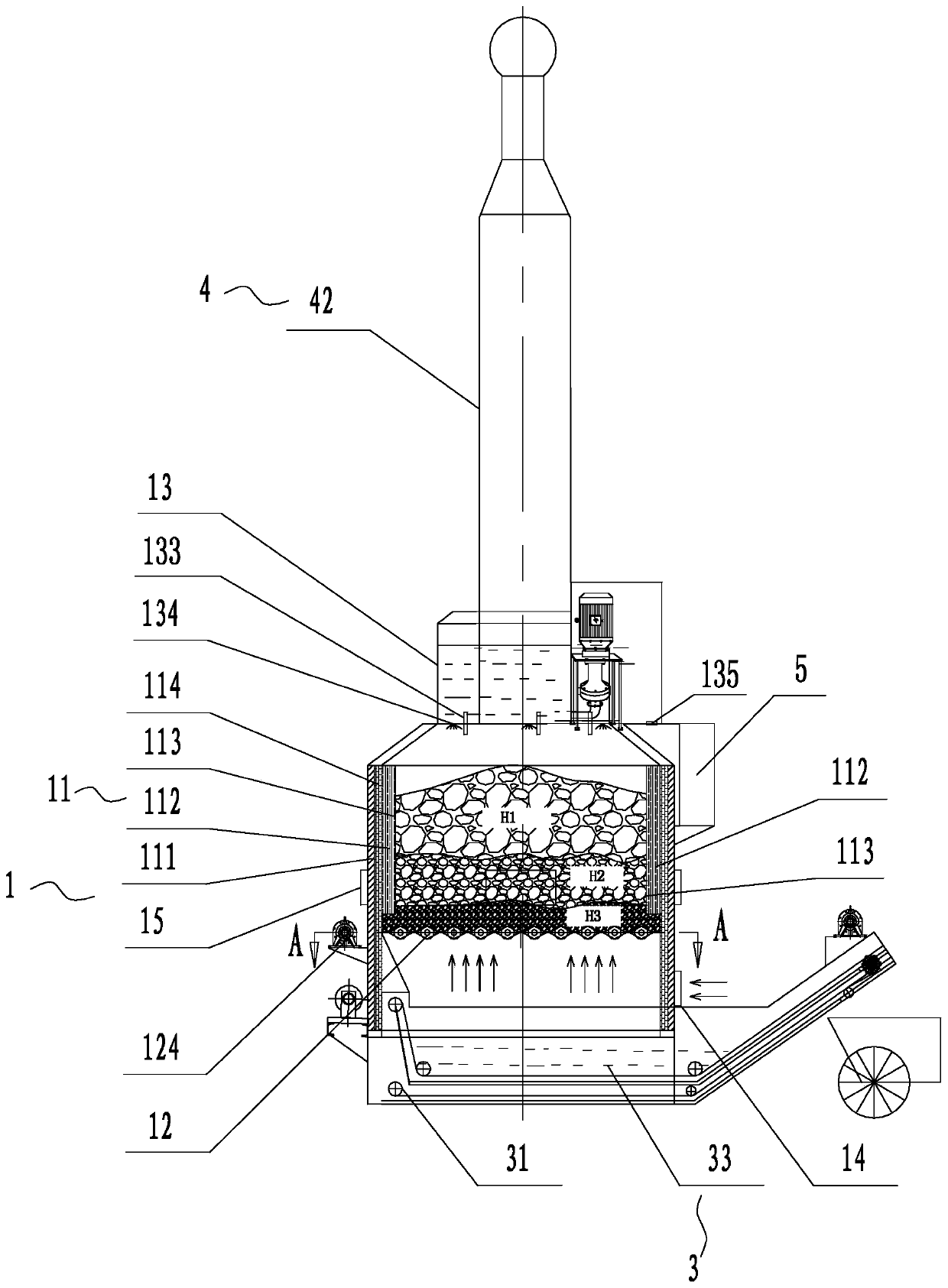

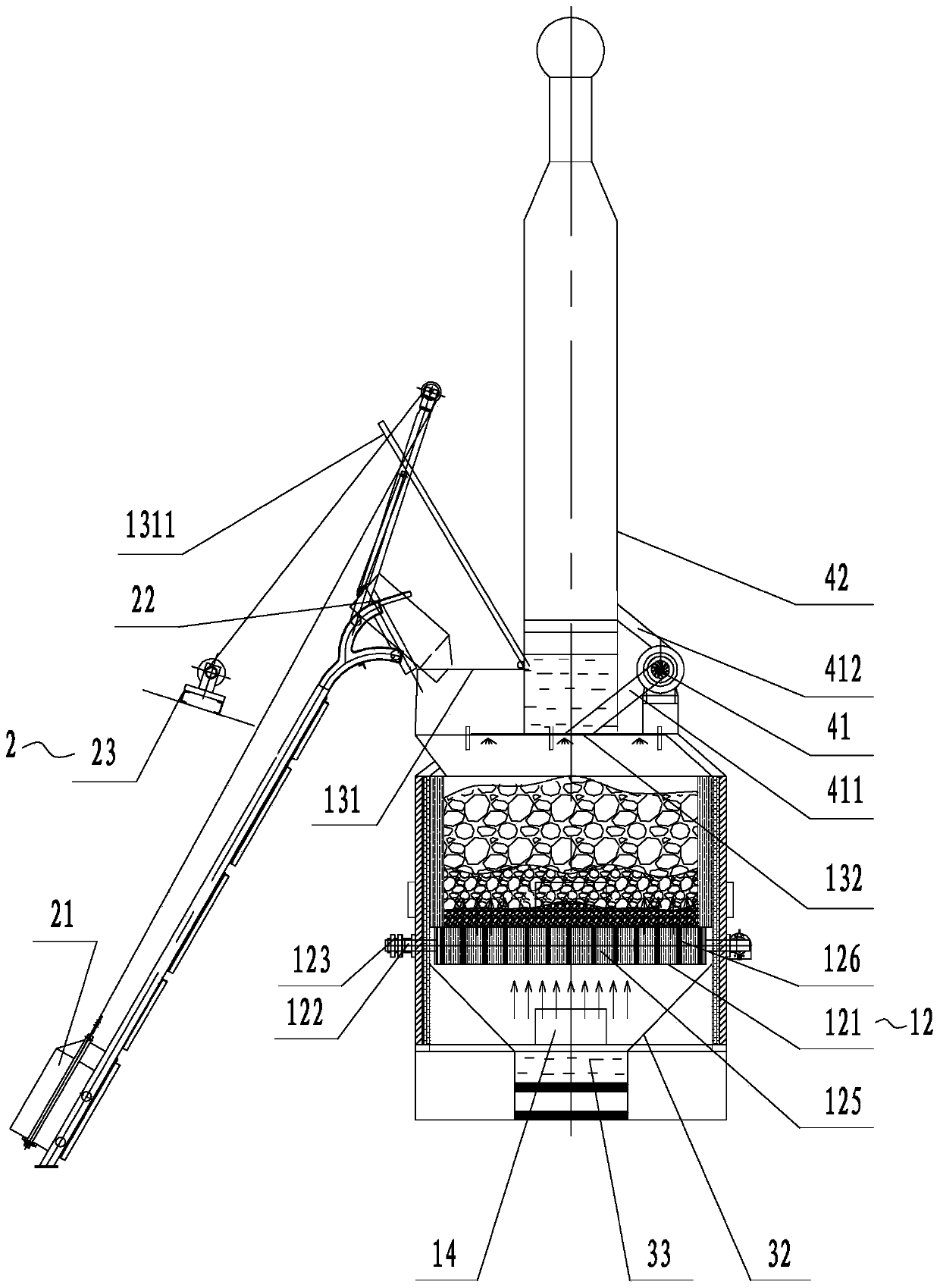

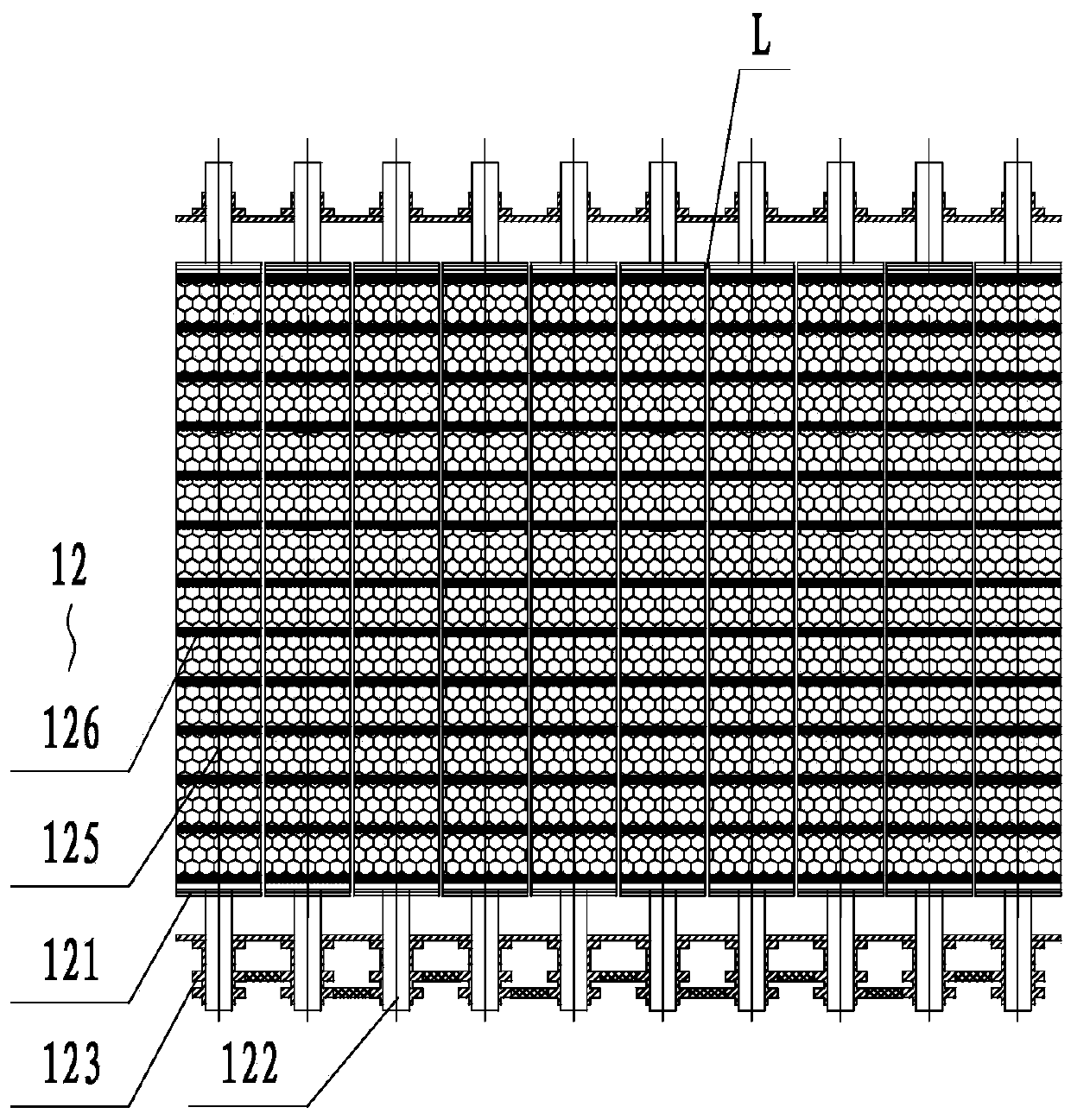

[0083] S1. Furnace start-up preparation for normal production: The domestic waste flash mineralization processor used includes a furnace body 1, a feeding system 2, an ash discharge system 3, a flue gas purification system 4, and an electrical control box 5. The furnace body 1 includes a furnace wall 11 located at the side of the furnace body, a fire grate 12 located at the lower part of the furnace body, and a water tank 13 located at the top of the furnace body; the fire grate 12 is a movable fire grate that can rotate 360°, and the fire grate 12 includes Fire grate shell 121, rotating shaft 122, sprocket wheel 123, pyroelectric honeycomb ceramic body 125, permanent magnet 126; Described fire grate shell 121 is the hollow shell with different vertical and horizontal dimensions on the broken section; The above grate shell 121 is evenly provided with ventilation holes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com