Weaving method of warp-knitted seamless bottomless jacquard double-sided mesh fabric

A mesh weave, seamless technology, used in warp knitting, textiles, papermaking, knitting, etc., can solve problems such as inability to meet fabric requirements, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

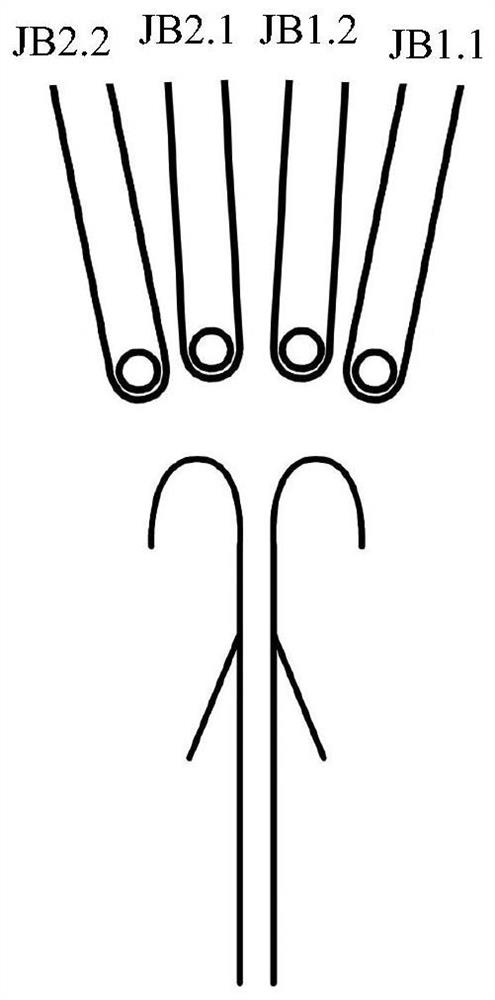

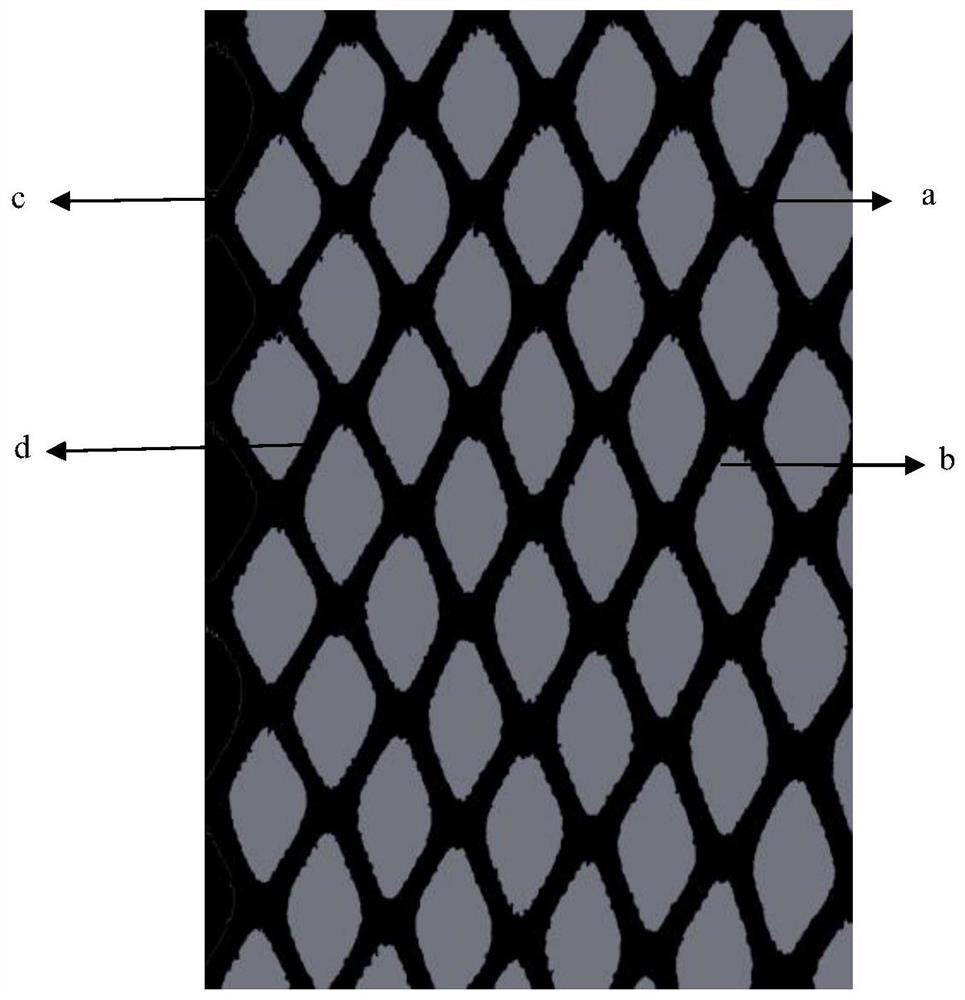

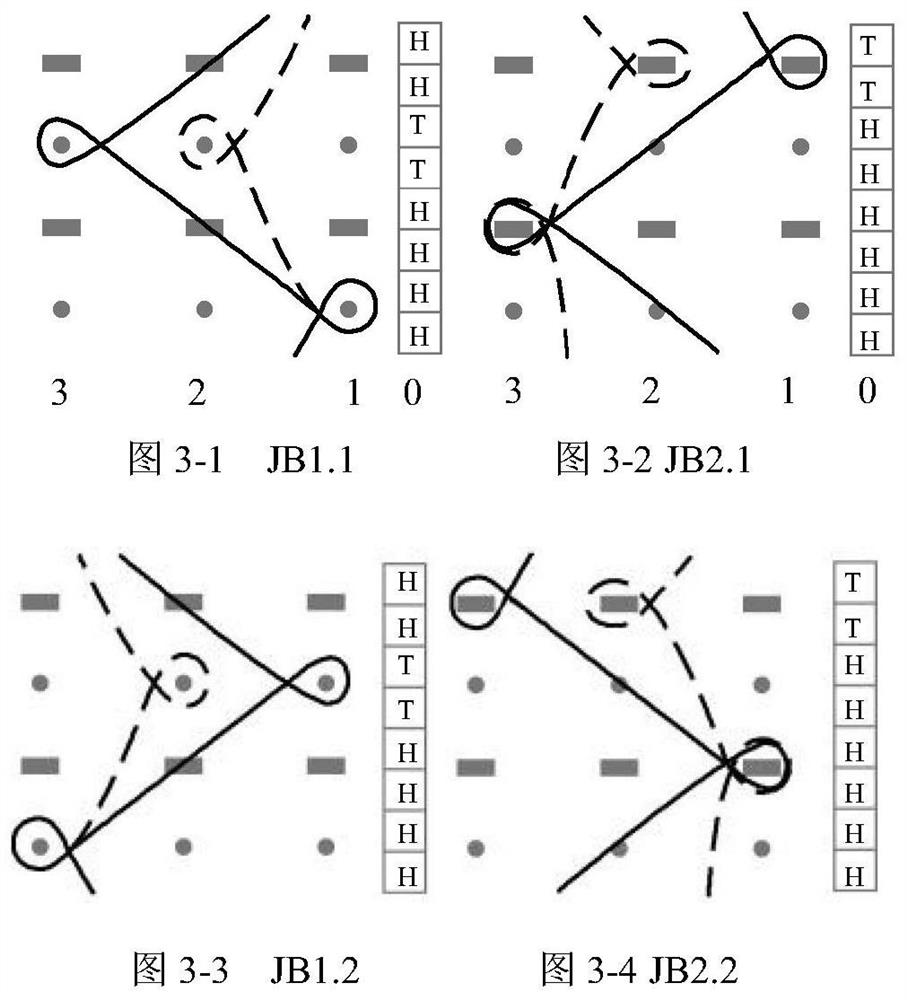

[0038] The warp-knitted seamless bottomless jacquard double-sided mesh fabric of the present invention is produced on a double-needle-bed Jarascher warp knitting machine whose gauge is E32 (32 needles per inch), and the model is RDPJ6 / 2, double-needle The bed warp knitting machine includes a front needle bed and a rear needle bed, and there are 2 comb bars in total; figure 1 As shown, in the production process of the present invention, 2 comb bars are used, and 2 half gauge Jacquard comb bars are used in the front and rear needle beds to form 1 full gauge gauge bar, which are the comb bars arranged in sequence at the front needle bed respectively. JB1.1, bar JB1.2, and bar JB2.1 and JB2.2 located on the rear needle bed; the knitting needles on the needle bed of a double-needle bed warp knitting machine are in the front position from the machine head direction to the machine tail direction The needle gaps of adjacent knitting needles are numbered, and the needle gaps of the kni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com