Polyether-ether-ketone composite material surface chemical plating pre-treatment technology

A technology of composite materials and polyether ether ketone, which is applied in metal material coating technology, liquid chemical plating, coating, etc., can solve the problems of low product qualification rate and low bonding strength, and achieve stable process and high surface tension , Improve the effect of binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A pretreatment process before electroless plating on the surface of a polyether ether ketone composite material, comprising the following steps:

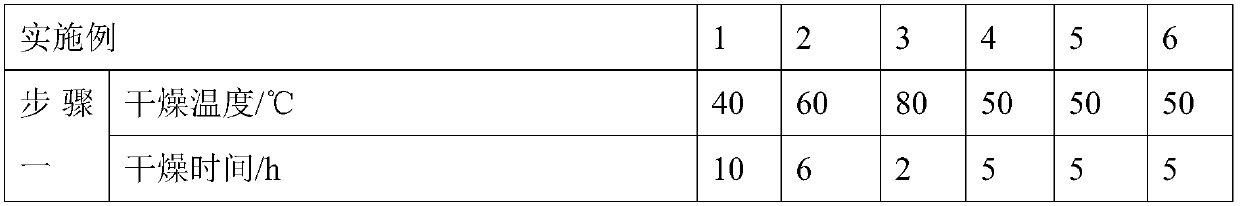

[0039]Step 1. Stress relief: wash the surface of the finished polyether ether ketone composite material with ethanol for at least 2 times, then put it in an oven at a temperature of 40-80°C and dry it for 2-10 hours. After drying, polyether is obtained Etherketone composite parts are ready for use;

[0040] Step 2. Degreasing: put the polyetheretherketone composite material part in step 1 into the dewaxed water at a temperature of 50-80 °C for ultrasonic cleaning for 5-30 minutes, and obtain the degreased polyether ether ketone composite material part for use;

[0041] Step 3. Pretreatment: Wash the polyether ether ketone composite material parts degreased in step 2 with water for at least 2 times, then soak them in the pretreatment solution at a temperature of 20-30°C for at least 5 minutes, take them out and wash them with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com