Anti-emulsifying and demulsifying cleanup additive and preparation method thereof

A demulsification aid and demulsifier technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of rising cost of fracturing fluid materials, single performance, inconvenient use of additives, etc., to reduce the surface interface Tension, good drainage performance, the effect of less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

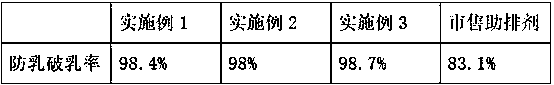

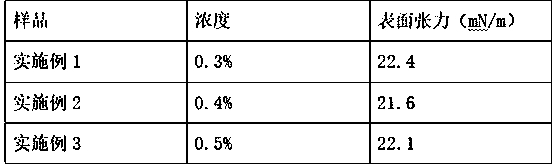

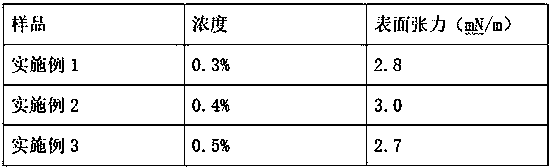

Examples

preparation example Construction

[0026] The preparation method of the biosurfactant of the present invention is: take the fermentation broth of Acinetobacter acetic acid strain in a centrifuge with a rotating speed of 10000rpm for 20 minutes, take the supernatant, and adjust the supernatant with 2mol / L concentrated hydrochloric acid PH to 2.0, let stand overnight at 4°C, centrifuge the solution at 10000rpm for 20min, discard the supernatant, resuspend the precipitate with a small amount of distilled water, adjust the pH to 7.0 with concentrated NaOH, then place the sample at -20°C for 5h , Freeze-dried for 24 hours under vacuum conditions, the resulting sample was dissolved in an excess of anhydrous methanol ultrasonically, centrifuged for 10 minutes in a centrifuge at a speed of 14000 rpm, the supernatant was taken, and the supernatant was subjected to rotary evaporation at 46°C. Then the biosurfactant is obtained.

[0027] The preparation method of the fluorocarbon surfactant of the present invention is as fol...

Embodiment 1

[0029] An anti-emulsification and demulsification aid, which is composed of the following components in parts by mass: 0.5 parts of fluorocarbon surfactant, 3 parts of 1210 active agent, 1 part of CAB-35 active agent, 98 parts of softened water, and demulsifier SP -169 0.5 parts, GE-189 0.3 parts and biosurfactant 0.2 parts.

[0030] It includes the following steps: in a clean 2-square stainless steel reactor, add 450 kg of softened water, start the mixer to slowly add 50 kg of fluorocarbon surface activity, turn on the electric heating switch, raise the temperature in the kettle to 50 degrees, and slowly add 300 1210 kg of active agent and 100 kg of CAB-35 active agent, keep the temperature in the kettle at 50 degrees and stir for two hours, then add 50 kg of demulsifier SP-169, 30 kg of GE-189 and 20 kg of biosurfactant, stir for 1 hour, Then add 530 kg of demineralized water and stir for 1 hour, turn off the electric heating, and wait until the temperature in the kettle drops ...

Embodiment 2

[0033] An anti-emulsification and demulsification aid, which is composed of the following components in parts by mass: 4 parts of fluorocarbon surfactant, 1 part of 1210 active agent, 3 parts of CAB-35 active agent, 94 parts of softened water, and demulsifier SP -169 0.4 parts, GE-189 0.2 parts and biosurfactant 0.1 parts.

[0034] It includes the following steps: in a clean 2-square stainless steel reactor, add 400 kg of softened water, start the mixer to slowly add 400 kg of fluorocarbon surface activity, turn on the electric heating switch, raise the temperature in the kettle to 55 degrees, and slowly add 100 1210 kg of active agent and 300 kg of CAB-35 active agent, keep the temperature in the kettle at 55 degrees and stir for three hours, then add 40 kg of demulsifier SP-169, 20 kg of GE-189 and 10 kg of biosurfactant, and stir for 2 hours. Then add 540 kg of demineralized water and stir for 1 hour, turn off the electric heating, and wait until the temperature in the kettle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com