High-strength anti-aging self-knotting material and its preparation method

An anti-aging, self-knotting technology, applied in the field of polyurethane synthesis, can solve problems such as strong odor, short construction operation time, and damage to the environment, and achieve the effects of prolonging operation time, improving mechanical properties, and improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

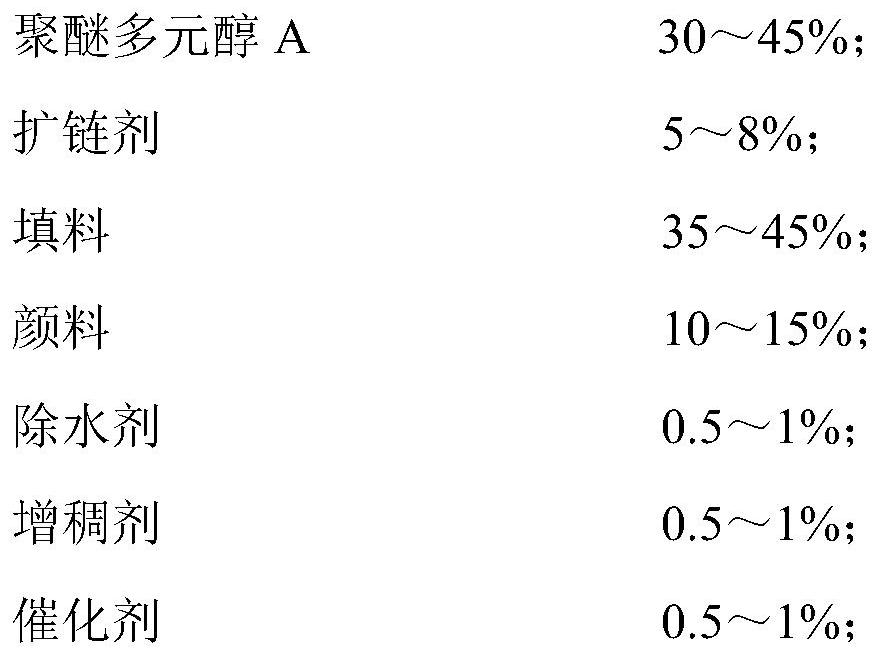

Method used

Image

Examples

Embodiment 1

[0035] (1) Put 100g of polyether polyol DL-1000 and 200g of MN3050 into the reaction kettle, start stirring, add 80g of MOCA, 450g of 800 mesh talc powder, and 140g of iron oxide red under stirring state, heat up to 95°C, and vacuum dehydrate to 0.05% Next, add water remover (Zoldine MS-Plus) 10g, thickener (BYK-410 and Deqian 229, mass ratio 1:1) 10g, catalyst (N,N-bis(dimethylaminopropyl ) isopropanolamine and dibutyltin dilaurate, the mass ratio is 1:2) 10g, stirred for 35min, and packed into barrels to obtain the product.

[0036] (2) Put 270g of polyether polyol MN3050 and 180g of N330 into the reaction kettle, raise the temperature at 95°C, and dehydrate for 1.5h under the condition of vacuum degree -0.01MPa until the moisture content is less than 0.1%. After cooling down to 35°C, add All TDI 150g, 2,6-di-tert-butyl-4-methylphenol 15g and 4-benzoyloxy-2,2,6,6-tetramethylpiperidine 15g, heated to 80°C for reaction 2h, then add 100g of hexamethylene diisocyanate biuret an...

Embodiment 2

[0039] (1) Put 150g of polyether polyol DL-1000 and 300g of MN3050 into the reaction kettle, start stirring, add 50g of MOCA, 355g of 800 mesh talc powder, and 150g of iron oxide red under stirring state, heat up to 90°C, and vacuum dehydrate to 0.05% Next, add 5g of water remover (Zoldine MS-Plus), 5g of thickener (BYK-410 and Deqian 229, the mass ratio is 1:1), 5g of catalyst (N,N-bis(dimethylaminopropyl ) 5g of isopropanolamine and zinc isooctanoate in a mass ratio of 1:2, stirred for 40min, and packed into barrels to obtain the product.

[0040] (2) Put 330g of polyether polyol MN3050 and 220g of N330 into the reaction kettle, raise the temperature at 90°C, and dehydrate for 2 hours under the condition of vacuum degree -0.01MPa until the moisture content is less than 0.1%. After cooling down to 30°C, add all TDI 120g, 2,6-di-tert-butyl-4-methylphenol 10g and 4-benzoyloxy-2,2,6,6-tetramethylpiperidine 10g, heated to 70°C for 2.5 h, then add 80 g of hexamethylene diisocyana...

Embodiment 3

[0043] (1) Put 140g of polyether polyol DL-1000 and 280g of MN3050 into the reaction kettle, start stirring, add 60g of MOCA, 393g of 600 mesh talc powder, and 100g of iron oxide red under stirring state, heat up to 100°C, and vacuum dehydrate to 0.05% Next, add water remover (Zoldine MS-Plus) 10g, thickener (BYK-410 and Deqian 229, mass ratio 1: 1) 10g, catalyst (N,N-bis(dimethylaminopropyl) ) isopropanolamine and dibutyltin dilaurate, the mass ratio is 1:2) 7g, stirred for 30min, and packed into barrels to obtain the product.

[0044] (2) Put 300g of polyether polyol MN3050 and 200g of N330 into the reaction kettle, raise the temperature at 100°C, under the condition of vacuum degree -0.01MPa, dehydrate for 1h until the moisture content is less than 0.1%, after cooling down to 40°C, add all TDI 135g, 2,6-di-tert-butyl-4-methylphenol 15g and 4-benzoyloxy-2,2,6,6-tetramethylpiperidine 15g, heat up to 90°C and react for 1h , then add 90g of hexamethylene diisocyanate biuret an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap