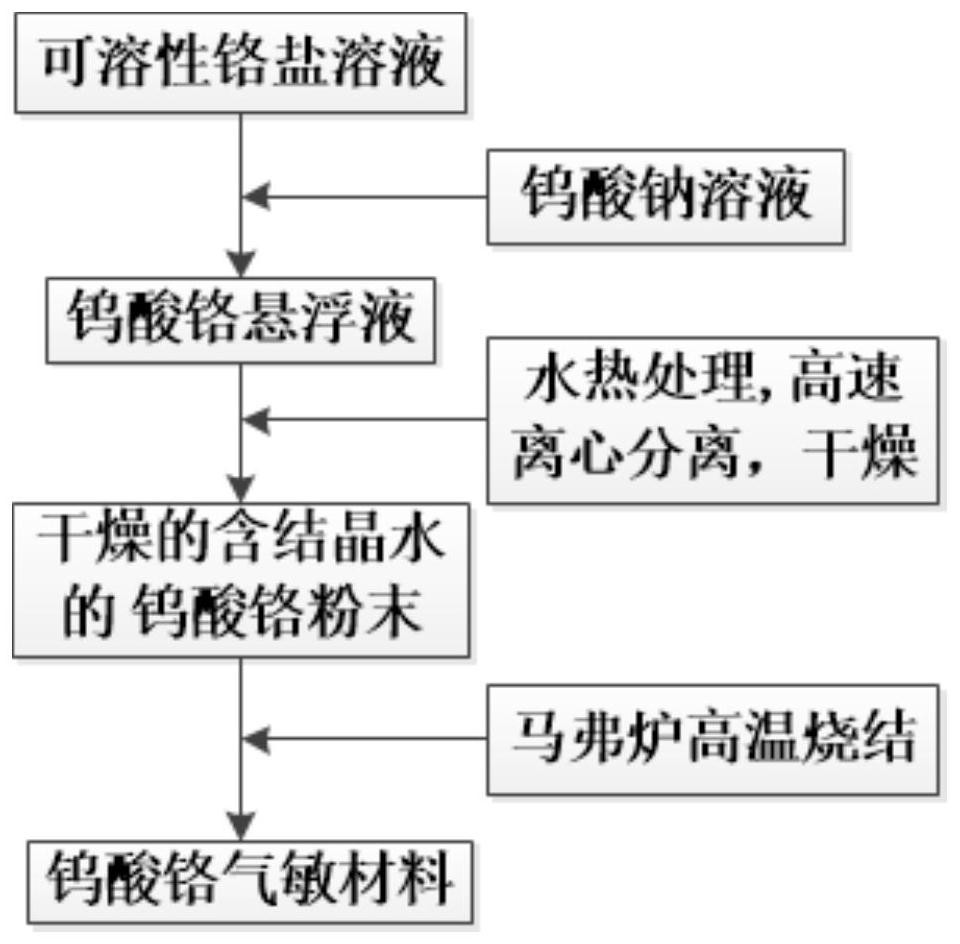

Preparation method of chromium tungstate gas sensitive material for acetone gas sensor

An acetone gas-sensing and gas-sensing material technology, which is applied in the field of preparation of chromium tungstate gas-sensing materials, can solve the problems of being susceptible to external environment interference, poor stability consistency, and long preparation period, and achieves high sensitivity and good stability. , the effect of reducing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

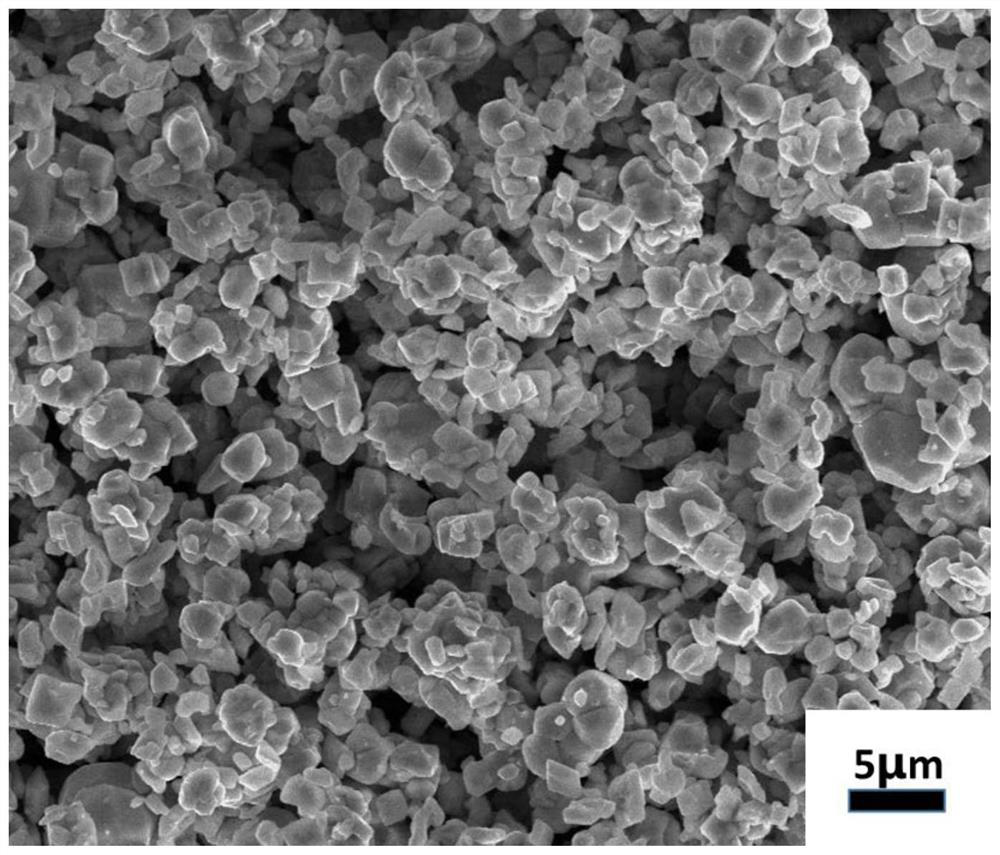

Image

Examples

Embodiment 1

[0050] The first step, the preparation of soluble chromium salt solution:

[0051] According to the mass ratio of the amount of soluble chromium salt and sodium tungstate dihydrate is 2:1, weigh 3.9218g of raw material solid Cr 2 (SO 4 ) 3 ·xH 2 O salt is placed in a container, and deionized water is added to form an aqueous solution of 33 mL of an aqueous solution with a chromium ion concentration of 0.6 mol / L, stirred at room temperature for 0.5 hours with a magnetic stirrer at a speed of 400 rpm, thus prepared Soluble chromium salt solution, ready for use;

[0052] The second step, the preparation of sodium tungstate solution:

[0053] According to the mass ratio of the amount of soluble chromium salt and sodium tungstate dihydrate is 2:1, weigh 3.2985g of raw material solid Na 2 WO 4 2H 2 O is placed in a container, and deionized water is added to prepare an aqueous solution of 25 mL of an aqueous solution with a concentration of tungstate ions of 0.4 mol / L, and sti...

Embodiment 2

[0061] The first step, the preparation of soluble chromium salt solution:

[0062] According to the mass ratio of the amount of soluble chromium salt and sodium tungstate dihydrate is 2:1, weigh 5.3288g of raw material solid CrCl 3 ·6H 2 O is placed in a container, and deionized water is added to form an aqueous solution with a chromium ion concentration of 0.7 mol / L. 29 mL of an aqueous solution is stirred at room temperature for 0.5 hours with a magnetic stirrer at a speed of 400 revolutions per minute, thereby preparing a soluble Chromium salt solution, ready for use;

[0063] The second step, the preparation of sodium tungstate solution:

[0064] According to the mass ratio of the amount of soluble chromium salt and sodium tungstate dihydrate is 2:1, weigh 3.2985g of raw material solid Na 2 WO 4 2H 2 O is placed in a container, and deionized water is added to prepare an aqueous solution of 17 mL of an aqueous solution with a concentration of tungstate ions of 0.6 mol / L,...

Embodiment 3

[0072] The first step, the preparation of soluble chromium salt solution:

[0073] The mass ratio of the amount of soluble chromium salt and sodium tungstate dihydrate is 2: 1, and 8.0030g of raw material solid Cr (NO 3 ) 3 9H 2 O is placed in a container, and deionized water is added to form a 30mL aqueous solution with a chromium ion concentration of 0.67 mol / L. Stir with a magnetic stirrer at room temperature for 0.5 hours at a speed of 400 rpm to obtain a soluble Chromium salt solution, ready for use;

[0074] The second step, the preparation of sodium tungstate solution:

[0075] According to the mass ratio of the amount of soluble chromium salt and sodium tungstate dihydrate is 2:1, weigh 3.2985g of raw material solid Na 2 WO 4 2H 2 O is placed in a container, and deionized water is added to prepare an aqueous solution of 20 mL of an aqueous solution with a concentration of tungstate ions of 0.5 mol / L, and stirred at room temperature for 0.5 hours with a magnetic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com