Shell punching forming method and device for aluminum film of lithium battery

A forming device and lithium battery technology, which is applied in the field of aluminum film punching and forming, can solve problems such as aluminum layer thickness bottlenecks, and achieve the effects of less material loss, less plastic deformation, and rapid shell forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

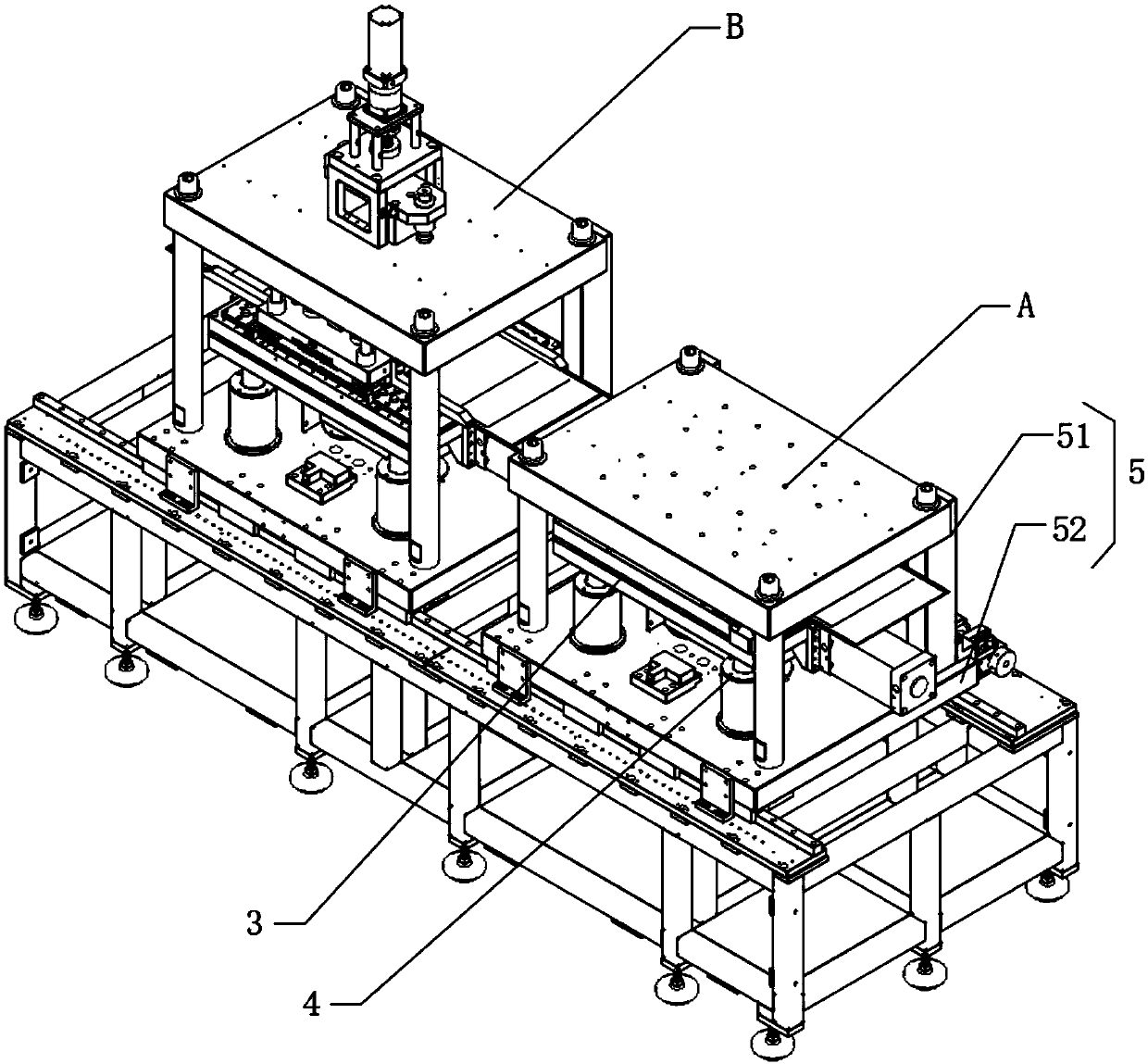

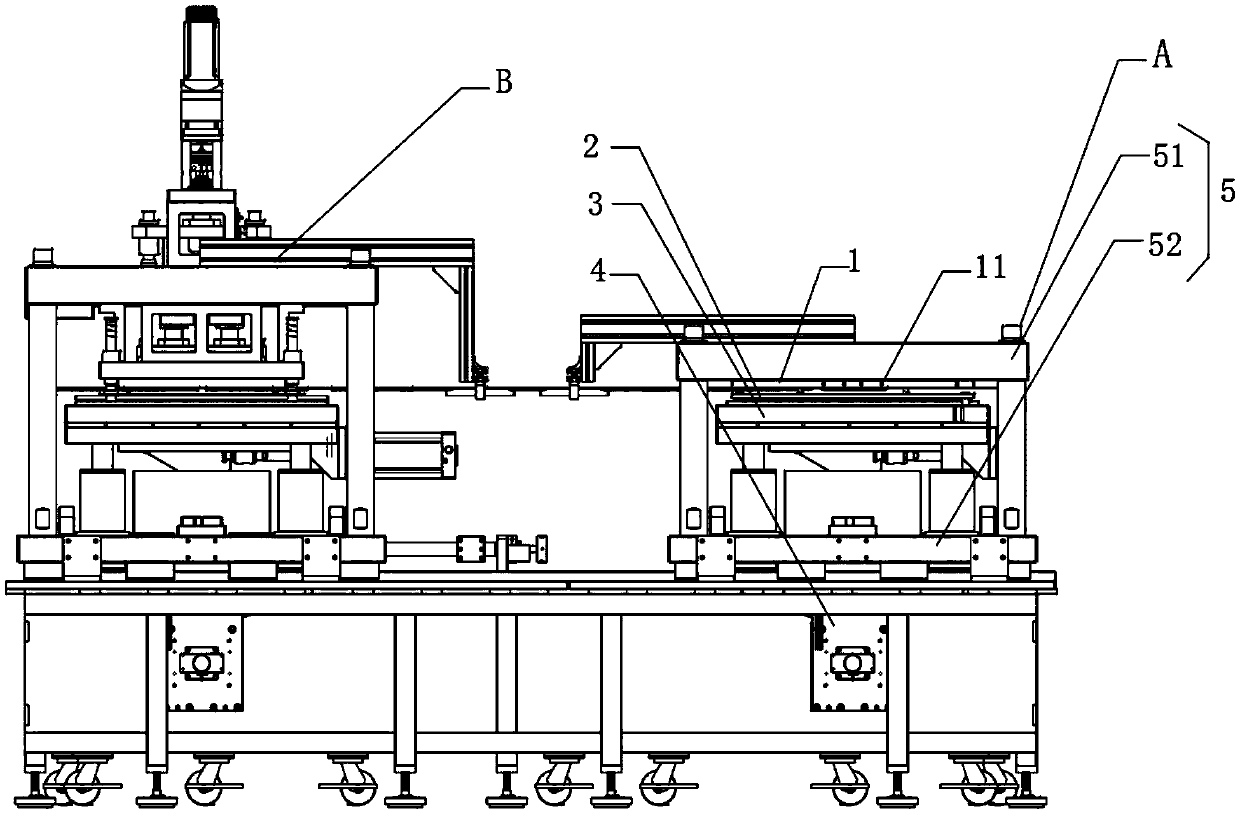

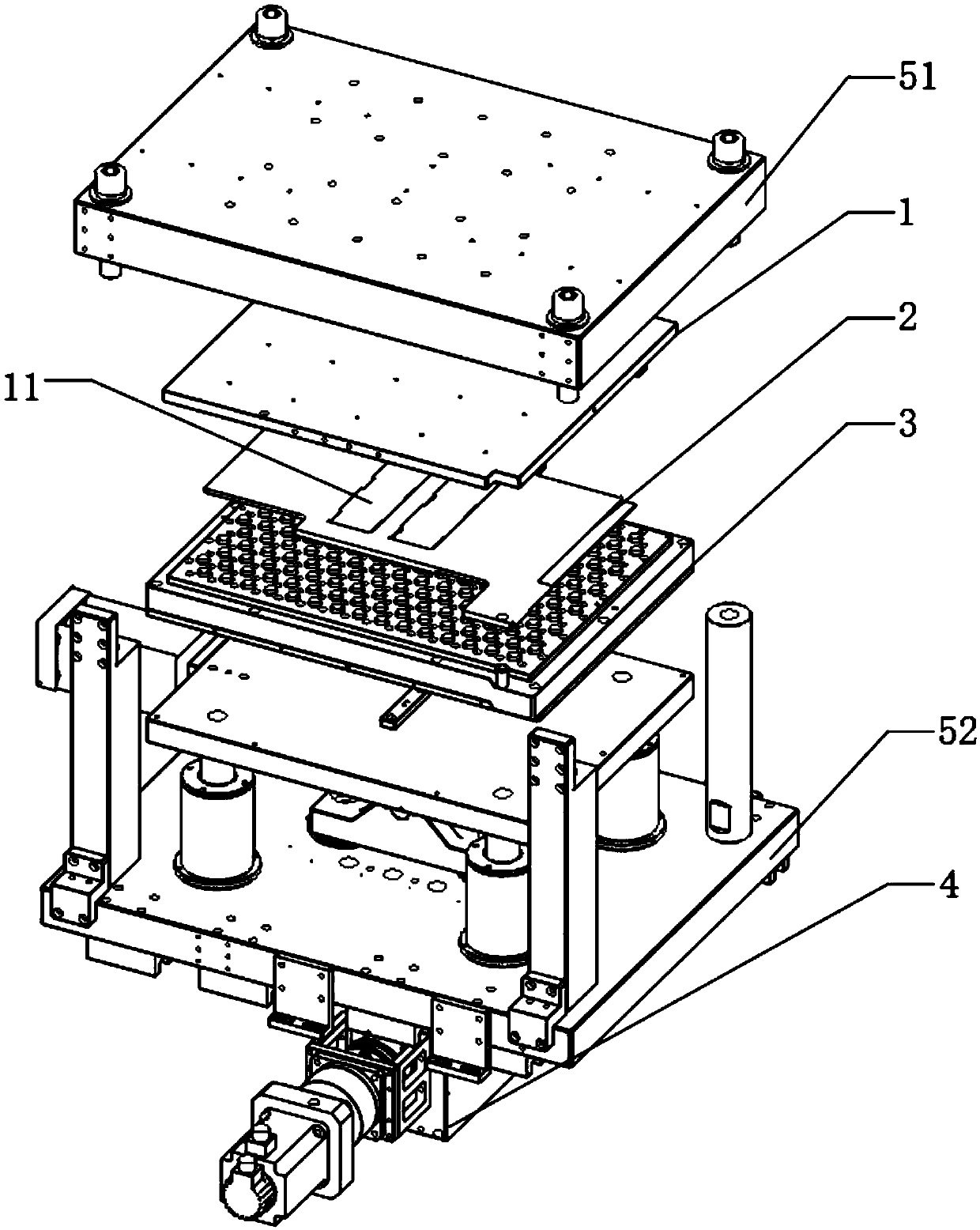

[0027] Such as Figure 1-4 As shown, a lithium battery aluminum film punching and forming device includes a pre-piercing device A and a shell punching device B arranged along the aluminum film conveying direction; Mechanism, upper platen 1, concave formwork 2, pressure adjustment mechanism 3 and lifting mechanism 4 of jacking pressure adjustment mechanism 3, the stamping mechanism is an air stamping mechanism, the upper platen 1 is provided with vent holes 11, the concave formwork 2. There is an escape space 21.

[0028] The pre-piercing pit device A includes a frame 5, the frame 5 is provided with an upper mold frame 51 and a lower template 52, the upper platen 1 is fixed on the bottom of the upper mold frame 51, and the pressure regulating mechanism 3 is arranged on the top of the lower template 52, The lifting mechanism 4 is used for jacking up the pressure regulating mechanism 3 . When working, the upper mold frame 51 and the upper platen 1 are fixed, and the aluminum fi...

Embodiment 2

[0042] Such as Figure 1-6 As shown, a method for punching and forming the aluminum film of a lithium battery. Firstly, the pre-punching device A is used to pre-pit the aluminum film, so that the aluminum film is deformed. The aluminum film is punched and formed.

[0043] The method for punching and forming the aluminum film of the lithium battery of the present invention first preforms the aluminum film through the pre-punching pit, punches out a deformation pit smaller than the actual punching pit size at the punching pit position, and participates in the plastic deformation of the aluminum film during this process There are many materials, which will not lead to the reduction of the aluminum film material in a certain place, and will not leave obvious plastic deformation boundary lines, which can eliminate the traces of pre-punching during the shell forming process, and will not cause adverse effects on the appearance of the aluminum-plastic film. influences. Because the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com