Cleaning and screening device for rice deep processing

A screening device and deep processing technology, which are applied in the directions of cleaning methods, sieves, cleaning methods and utensils using liquid, can solve the problems of difficult operation, secondary pollution of rice, poor cleaning effect, etc., and achieve convenient operation, improve quality, The effect of easy discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

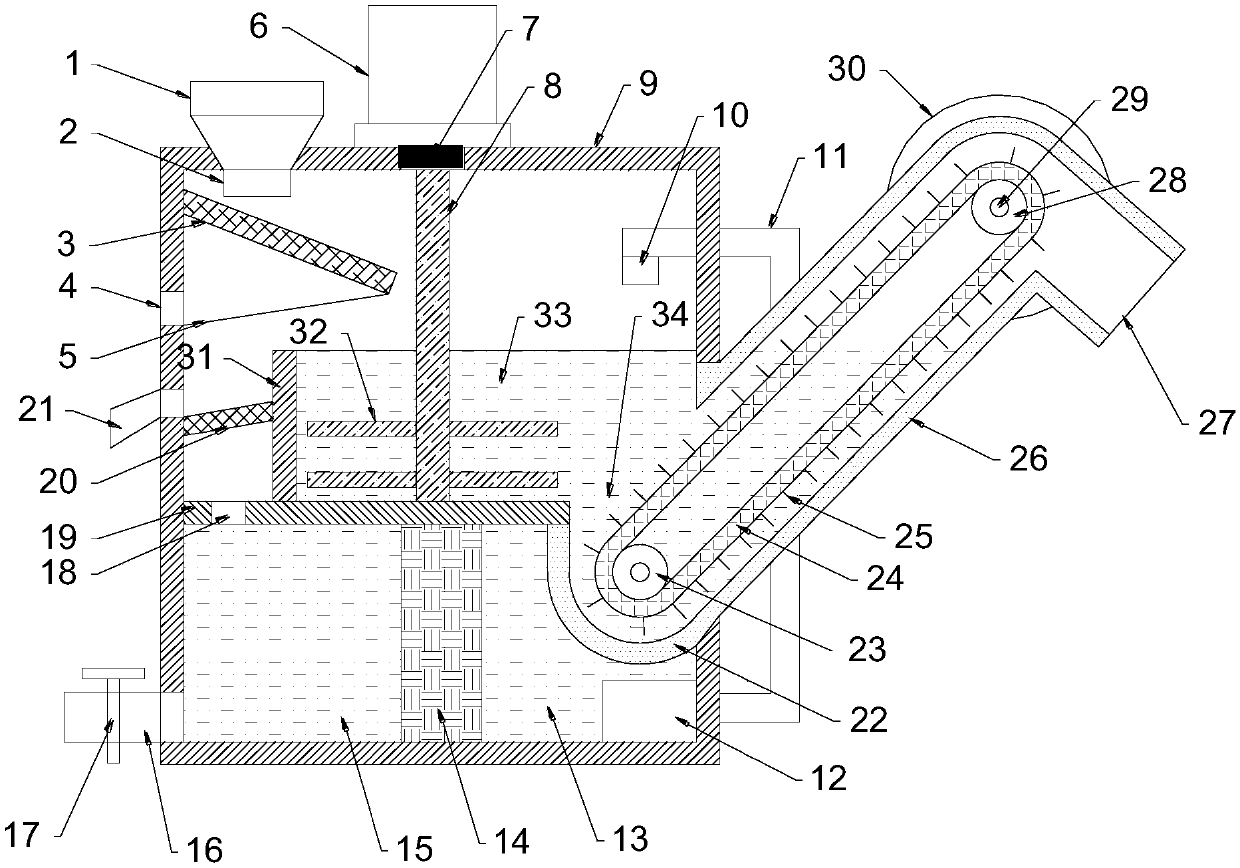

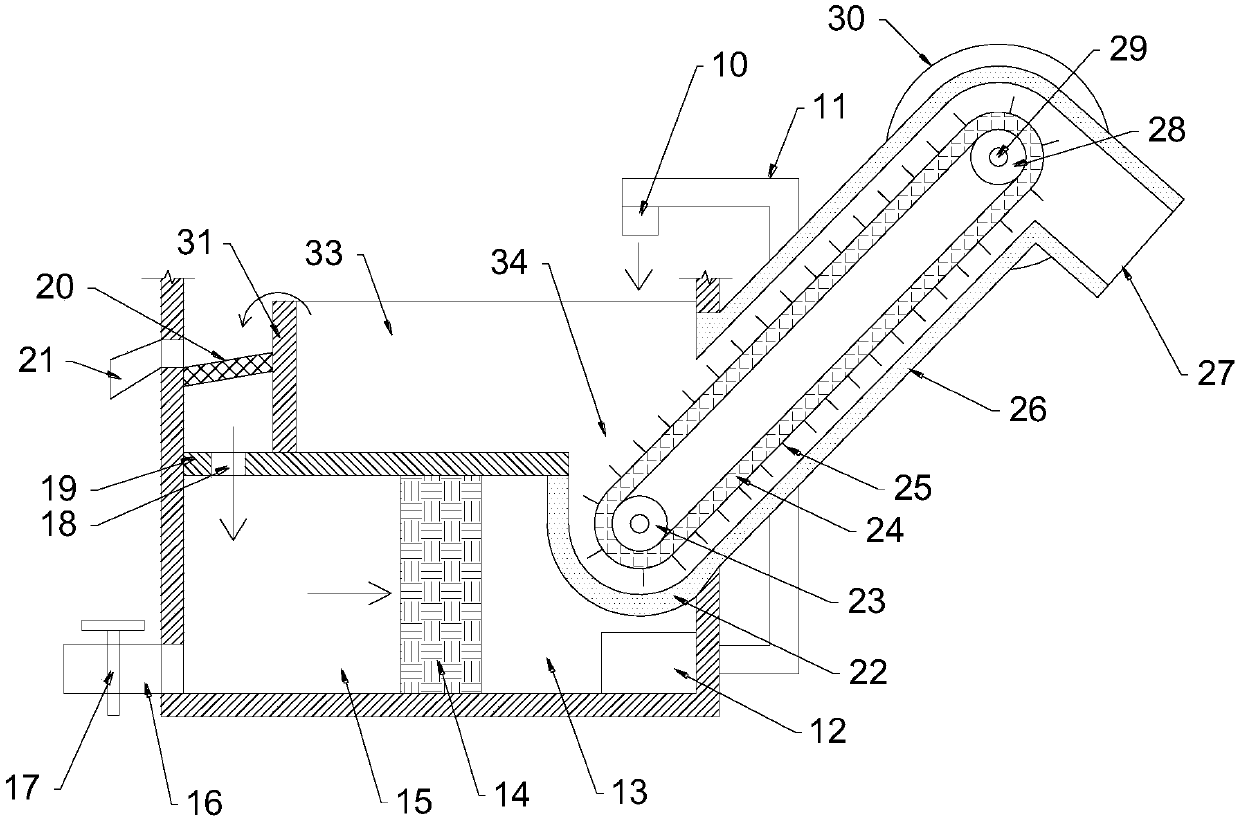

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] see Figure 1 ~ Figure 2 , in the present embodiment, a kind of cleaning and screening device for deep processing of rice, comprises screen cloth 3, cleaning box body 9, cleaning pool 13 and rice discharge tube 26, and described cleaning box body 9 upper ends are equipped with feeding funnel 1, feeding The bottom of the funnel 1 is provided with a blanking port 2 which communicates with the interior of the cleaning box 9, and a screen 3 is installed in the cleaning box 9 below the blanking port 2. The screen 3 is inclined and the angle of inclination is 10-45°. Described blanking opening 2 is arranged on the upper end top of screen cloth 3, and the bottom of screen cloth 3 is provided with waste material collection box 5, and waste material discharge port 4 is opened on the cleaning box body 9 of waste material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com