Mineral processing method and mineral processing system for improving the recovery rate of refractory zinc concentrate

A beneficiation method and a technology for zinc concentrate are applied in the field of beneficiation methods and systems for efficiently improving the recovery rate of refractory zinc concentrate, and can solve the problems of difficulty in controlling the grade of zinc concentrate, improving zinc recovery rate, and complex composition, and achieve economical Considerable benefits and environmental benefits, improved recovery rates, and cost reduction effects such as chemical consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The column machine united subsection asynchronous coarse concentrate regrinding method for lead selection includes the following steps:

[0026] A. After grinding the complex polymetallic lead-zinc ore, according to the principle of priority flotation, first flotation lead and then flotation zinc. By concentrating the tailings after lead selection, the concentration of the underflow pulp of the thickener reaches 50- 52%, add lime to the concentrated pulp, and adjust the pH value of the pulp to Lime fineness-200 mesh is greater than 90%, and the free CaO content is greater than 70%. Add CuSO4 as an activator to the slurry for stirring and activation. The amount of CuSO4 is Added to the activated pulp Butyl xanthate as collector, Pine oil is used as a foaming agent, and a quick roughing and two quick selections are completed through a quick separation flotation machine, and the grade of the quick selection zinc concentrate reaches The recovery rate of zinc reaches...

Embodiment 2

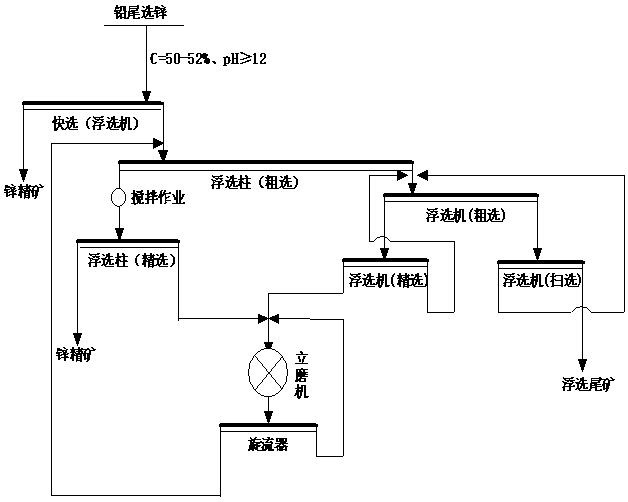

[0031]This high-efficiency, energy-saving and environment-friendly zinc concentrate mineral processing system includes a quick separation flotation machine, a rougher flotation column, a rougher flotation machine, a selection flotation column, a selection flotation machine, a sweep flotation machine, a vertical mill machine, cyclone, the concentrate outlet of the fast separation flotation machine is used to collect zinc concentrate, the tailings outlet of the fast separation flotation machine is connected with the pulp inlet of the rougher flotation column, and the rougher flotation column The concentrate outlet is connected to the pulp inlet of the fine selection flotation column, the tailings outlet of the rougher flotation column is connected to the pulp inlet of the rougher flotation machine, and the concentrate outlet of the finer flotation column is used to collect zinc concentrate, The tailings outlet is connected to the inlet of the vertical mill, the concentrate outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com