Catalyst for preparing dimethyl carbonate from epoxide, methanol and carbon dioxide, and preparation method and application thereof

A technology of dimethyl carbonate and epoxide, which is used in the catalyst, preparation method and application field for producing dimethyl carbonate from epoxide, methanol and carbon dioxide, can solve the problems of no research reports, etc., and achieve application prospects Compatible with wide range, easy large-scale application, and simple recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare the concentration of zinc ion to be 0.2g·ml -1 zinc nitrate solution, add HZSM-5 molecular sieve and impregnate for 12h, wherein ZSM-5 molecular sieve has a silicon-aluminum ratio of 70 and a specific surface area of 700m 2 g -1 , the particle size is 10000nm, and the average pore size is 0.5nm. Then dry at 80° C. for 2 hours, grind the obtained solid, and roast at 250° C. for 9 hours to obtain the desired modified molecular sieve catalyst. The mass percent content of zinc oxide in the prepared modified ZSM-5 molecular sieve catalyst is 0.5%.

[0034] The catalyst is used in the reaction to produce dimethyl carbonate. The reaction raw materials are propylene oxide and methanol, accounting for 30% of the total volume of the reactor, the molar ratio of epoxide and methanol is 5, tetraethylammonium chloride is added in the reaction system, and the molar ratio of this substance to propylene oxide is 0.2. The molar ratio of the molar number of metal components ...

Embodiment 2-11

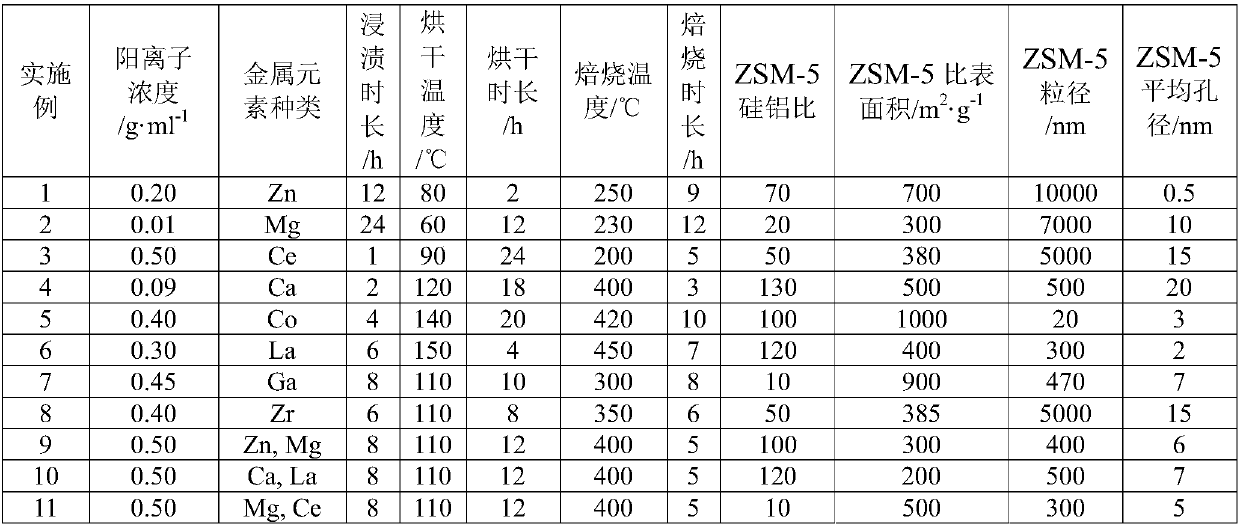

[0036] On the basis of Example 1, the catalyst composition, preparation process and reaction conditions were adjusted in Examples 2-11. See Attached Table 1 and Attached Table 2 for specific data. The reaction conditions and results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com