Filter plate for solid-liquid separation

A technology of solid-liquid separation and filter plate, applied in the direction of filtration separation, separation method, filter circuit, etc., can solve the problem of affecting the normal and continuous production of solid-liquid separation equipment, increasing the manufacturing cost of solid-liquid separation equipment, and poor economy and practicability of filter plates and other problems, to achieve good fit and surface flatness, simplify assembly and disassembly operations, and easy assembly and maintenance operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

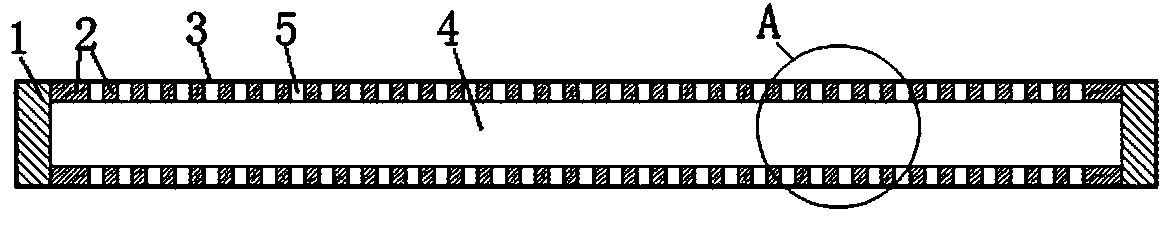

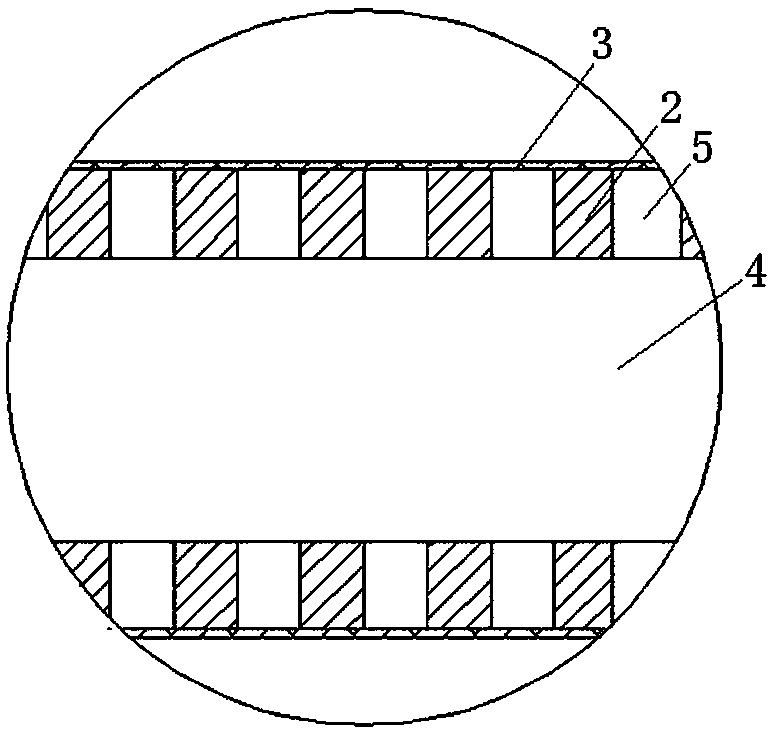

[0025] see figure 1 and figure 2 As shown, the present invention includes a plate frame and a filter cloth.

[0026] Wherein, the outer peripheral contour of the plate frame is a rectangular structure corresponding to the structure of the separation chamber of the solid-liquid separation equipment, which is mainly composed of a side plate 1 and two filter plates 2 . The side plate 1 is made of metal material, and the side plate 1 encloses a rectangular frame in the circumferential direction, and the rectangular frame formed by the side plate 1 matches the outer peripheral contour of the filter plate 2; the top of the side plate 1 is provided with a filtrate drain outlet, the filtrate outlet is connected with a filtrate outlet pipeline. The structures of the two filter plates 2 are the same; the outer contour of each filter plate 2 is a rectangular structure matching the frame surrounded by the aforementioned side plates 1, and each filter plate 2 is a bar-shaped grid struct...

Embodiment 2

[0030] The invention includes plate frame and filter cloth.

[0031] Wherein, the outer peripheral contour of the plate frame is a rectangular structure corresponding to the structure of the separation chamber of the solid-liquid separation equipment, which is mainly composed of side plates and two filter plates. The side plate is made of metal material, and the side plate forms a rectangular frame circumferentially around the wall structure. The rectangular frame surrounded by the side plate matches the outer peripheral contour of the filter plate; the top of the side plate is provided with a filtrate outlet, and the filtrate discharge The outlet is connected with a filtrate discharge pipe. The structures of the two filter plates are the same; the outer contour of each filter plate is a rectangular structure matching the frame surrounded by the aforementioned side plates, and each filter plate is a grid-like sieve structure, and the circle (or polygon, such as Rectangular, r...

Embodiment 3

[0035] The invention includes plate frame and filter cloth.

[0036] Wherein, the outer peripheral contour of the plate frame is a rectangular structure corresponding to the structure of the separation chamber of the solid-liquid separation equipment, which is mainly composed of side plates and two filter plates. The side plate is made of metal material, and the side plate forms a rectangular frame circumferentially around the wall structure. The rectangular frame surrounded by the side plate matches the outer peripheral contour of the filter plate; the top of the side plate is provided with a filtrate outlet, and the filtrate discharge The outlet is connected with a filtrate discharge pipe. The structure of the two filter plates is the same; the outer contour of each filter plate is a rectangular structure matching the frame surrounded by the aforementioned side plates, each filter plate is a strip-shaped grid structure, and the strip-shaped grid holes on the filter plate are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com