Lubricating oil filtering and purifying system

A technology of lubricating oil and filtering device, which is applied in the directions of lubricating composition, liquid separation through thermal diffusion, magnetic separation, etc., can solve the problems of single filtering function and can only filter solid particles, so as to improve the filtering effect and avoid the excessive flow of lubricating oil. More, to achieve the effect of automatic replenishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

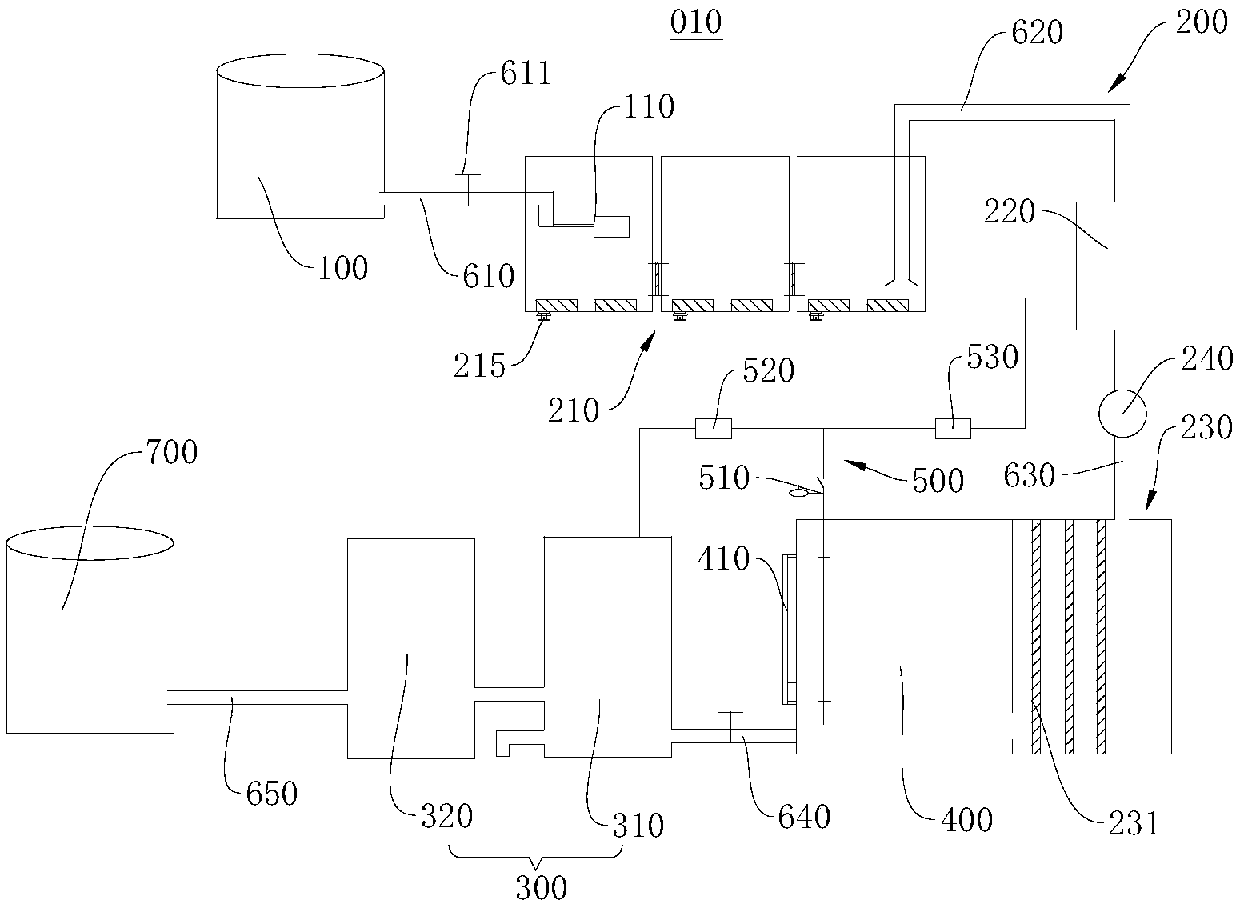

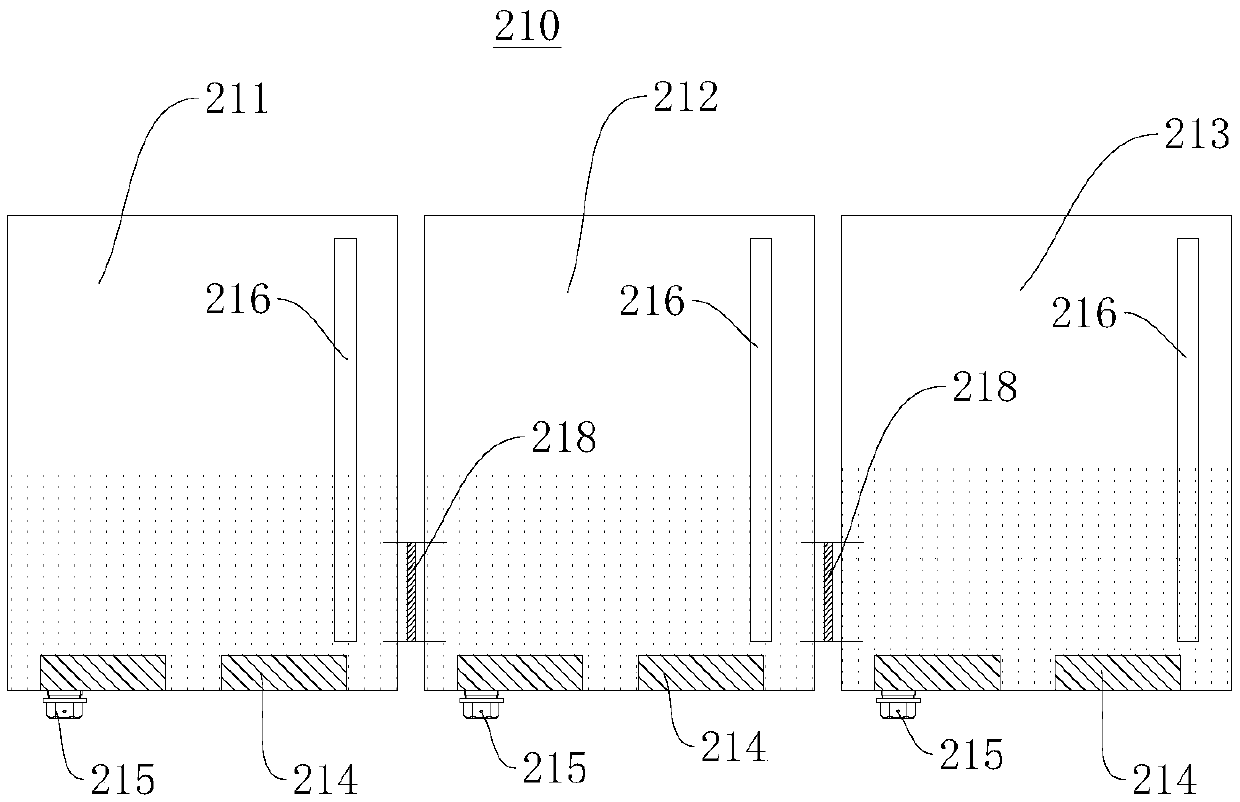

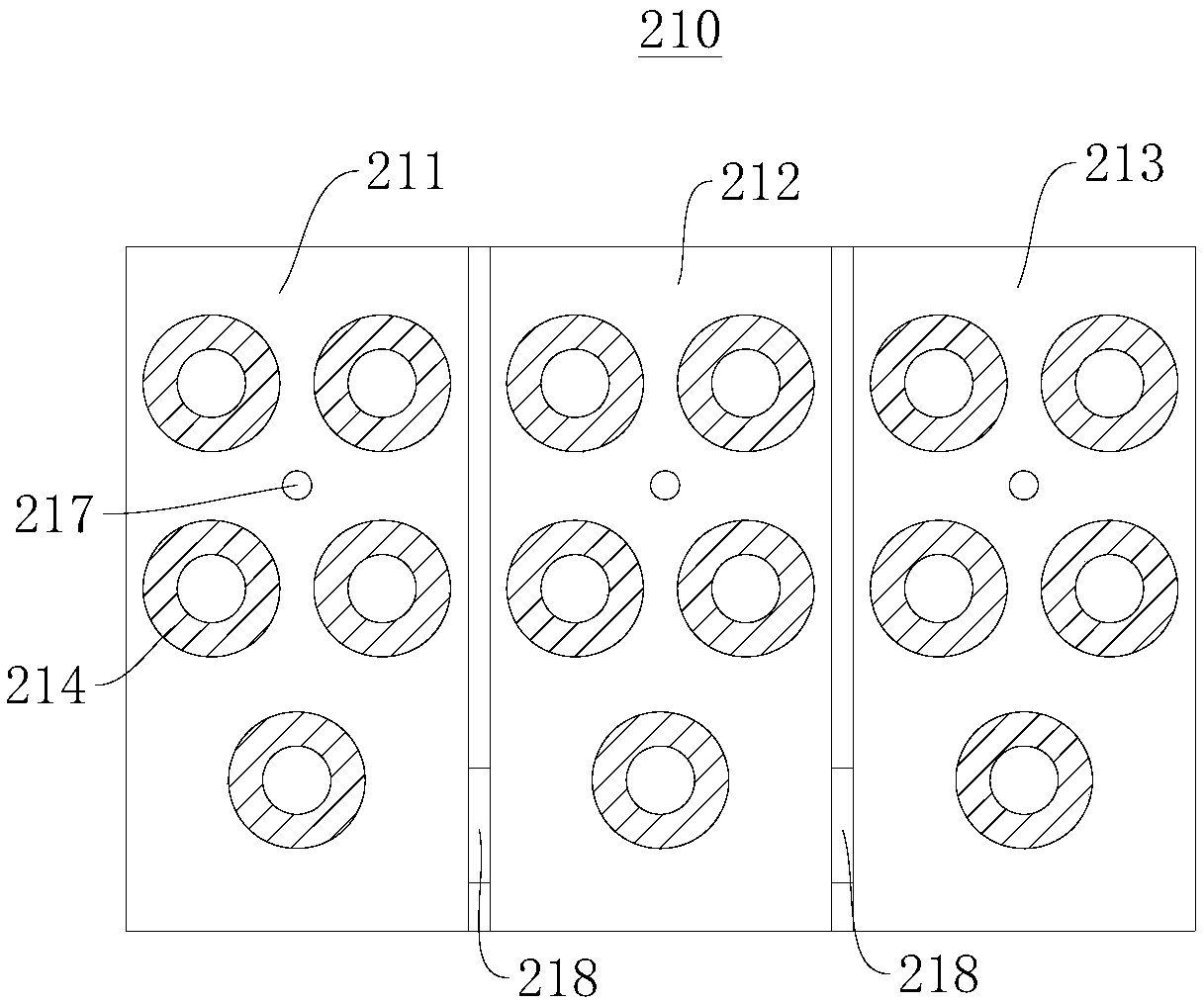

[0052] figure 1 It is a schematic diagram of the overall structure of the lubricating oil filtration and purification system 010 provided in this embodiment. Please refer to figure 1 , this embodiment provides a lubricating oil filtration and purification system 010, which includes a filter device 200 and a separation device 300 that are connected to each other. After the lubricating oil to be filtered and purified passes through the filter device 200, the solid impurities in the lubricating oil are filtered and removed, and the The latter lubricating oil enters the separation device 300 . The separation device 300 includes a centrifugal separation mechanism 310 and a heating separation mechanism 320 that communicate with each other. After the filtered lubricating oil enters the centrifugal separation mechanism 310, the water in the lubricating oil is separated and removed under the action of centrifugal force; the filtered lubricating oil enters the heating After the separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com