Method and apparatus for controlling jet dispensing by displacement measurement

A technology of displacement and injector, which is applied in the direction of injection device, injection device, printed circuit manufacturing, etc., and can solve problems such as poor contact and short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

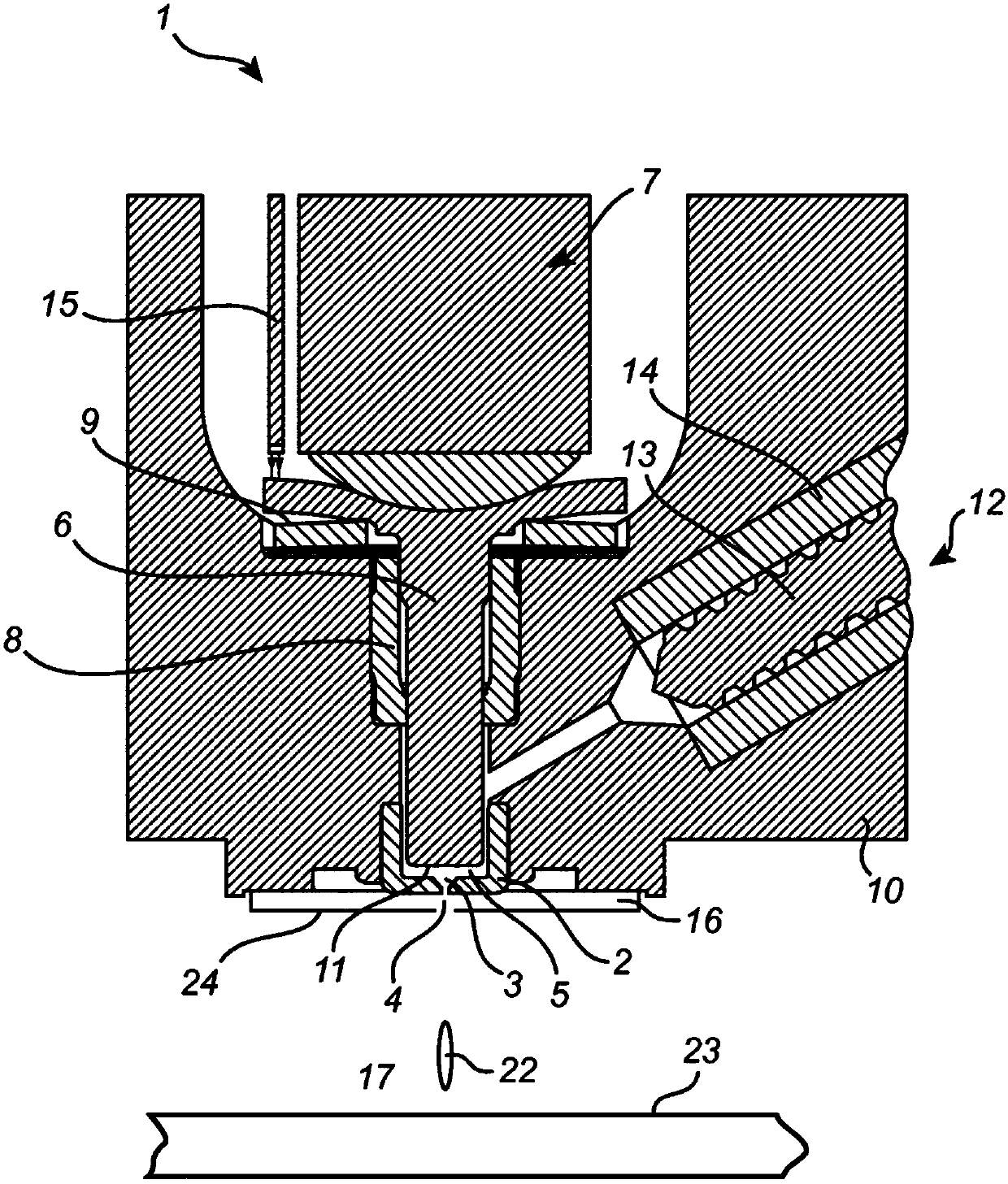

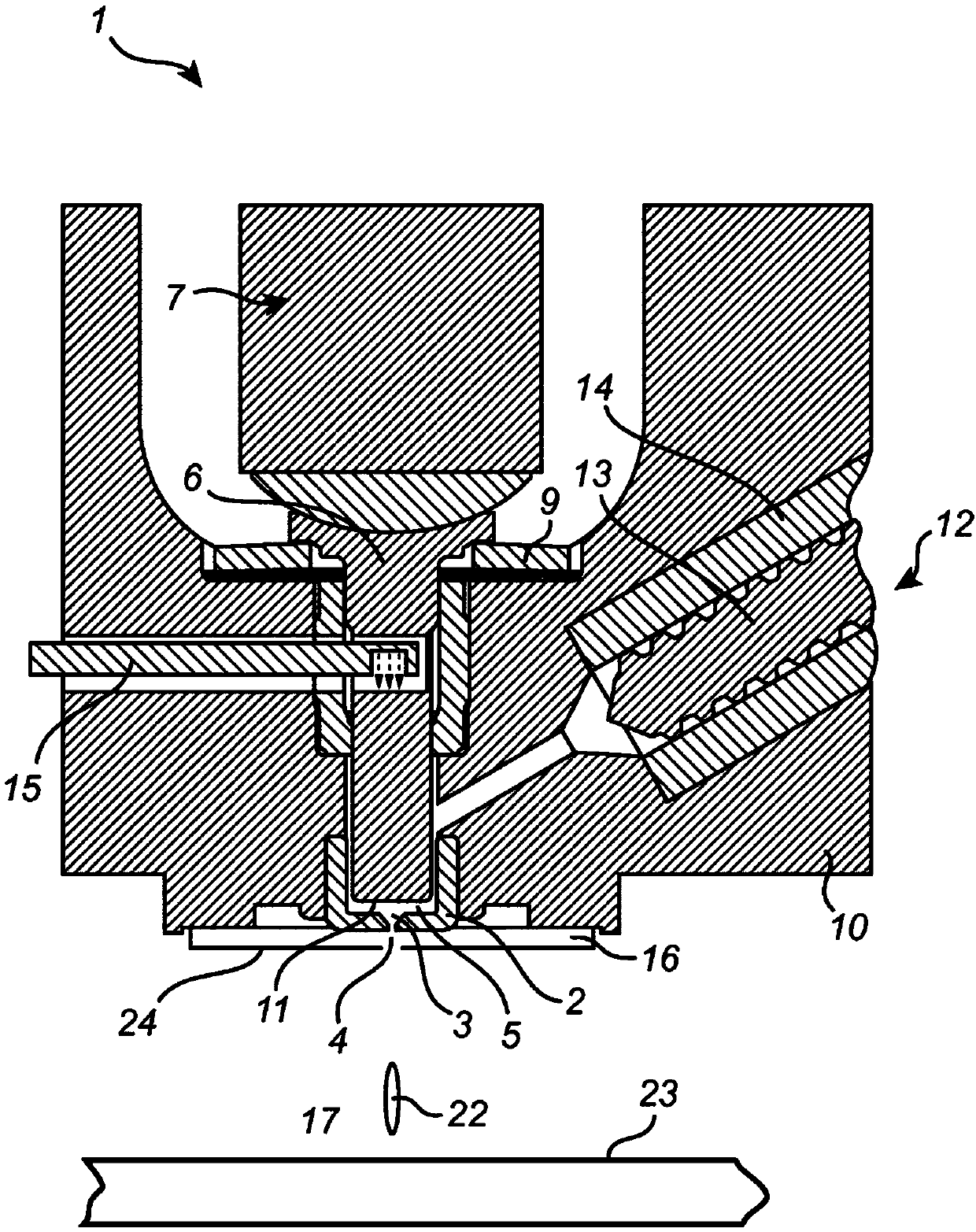

[0100] refer to figure 1 , shows a schematic diagram of an injector according to an embodiment of the technology.

[0101] The injector 1 comprises an assembly housing 10 and an impact device which in this embodiment may comprise a piezoelectric actuator 7 and a plunger or piston 6 operatively connected to the piezoelectric actuator 7 . The plunger 6 is axially movable while slidably extending through a bore in the bushing 8 . A cup spring 9 may be provided to elastically balance the plunger 6 on the assembly housing 10 and to provide a preload for the piezoelectric actuator 7 . A control unit (not shown) may intermittently apply a driving voltage to the piezoelectric actuator 7 to intermittently extend it according to solder pattern printing data, thereby reciprocating the plunger 6 relative to the assembly housing 10 .

[0102] Furthermore, the injector 1 may comprise a spray nozzle 2 operatively directed towards a substrate 23 onto which droplets 22 of the viscous medium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com