Apparatus for mounting evaporative piping of a liquefied gas fuel system to a vehicle

A liquefied gas fuel and fuel system technology, applied in the field of vehicles, can solve the problem that the evaporation pipe is not allowed to protrude horizontally or upward

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the term "liquefied gas" refers to liquefied natural gas (LNG) or liquefied biogas (LBG).

[0029] Hereinafter, the term "liquefied gas fuel system" refers to a fuel system for liquefied natural gas (LNG) or for liquefied biogas (LBG).

[0030] Hereinafter, the term "flexible pipe" refers to any flexible pipe, such as a hose, configured to convey fluid for use in a liquefied gas fuel system, which is bendable to a certain extent and has a certain flexibility in order to facilitate Handles the relative motion of the vehicle cabin relative to the liquefied gas fuel tank.

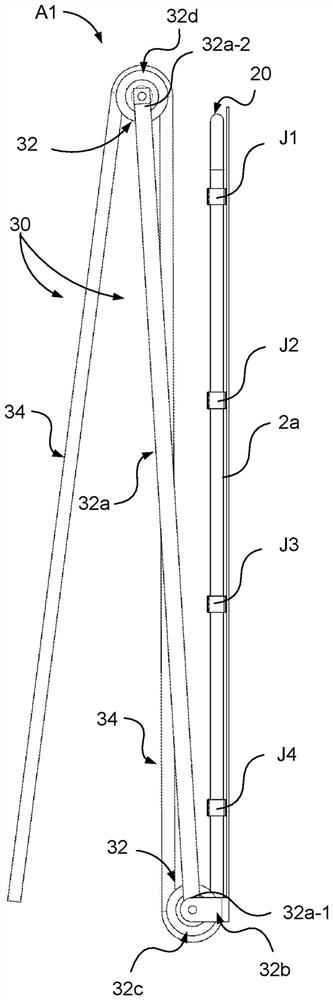

[0031] Hereinafter, the term "evaporation duct" refers to a duct, preferably a rigid duct, configured to discharge boil-off gas from a liquefied gas fuel tank of a liquefied gas fuel system. According to an embodiment, the pipe is made of stainless steel. Optionally, the evaporation conduit may be flexible, such as a flexible hose.

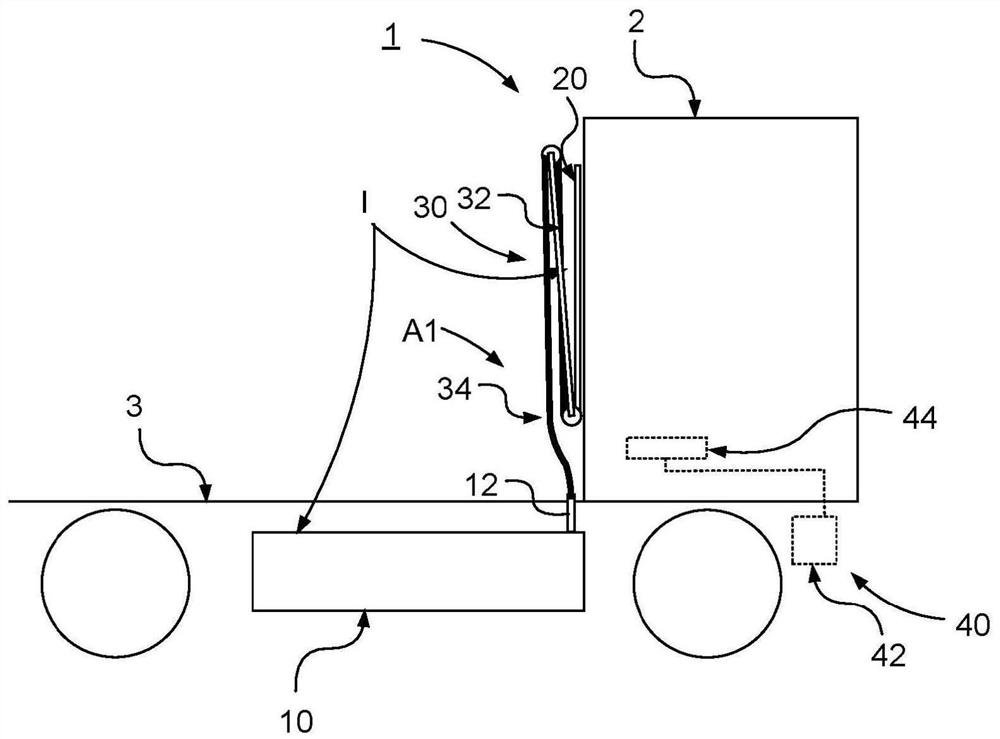

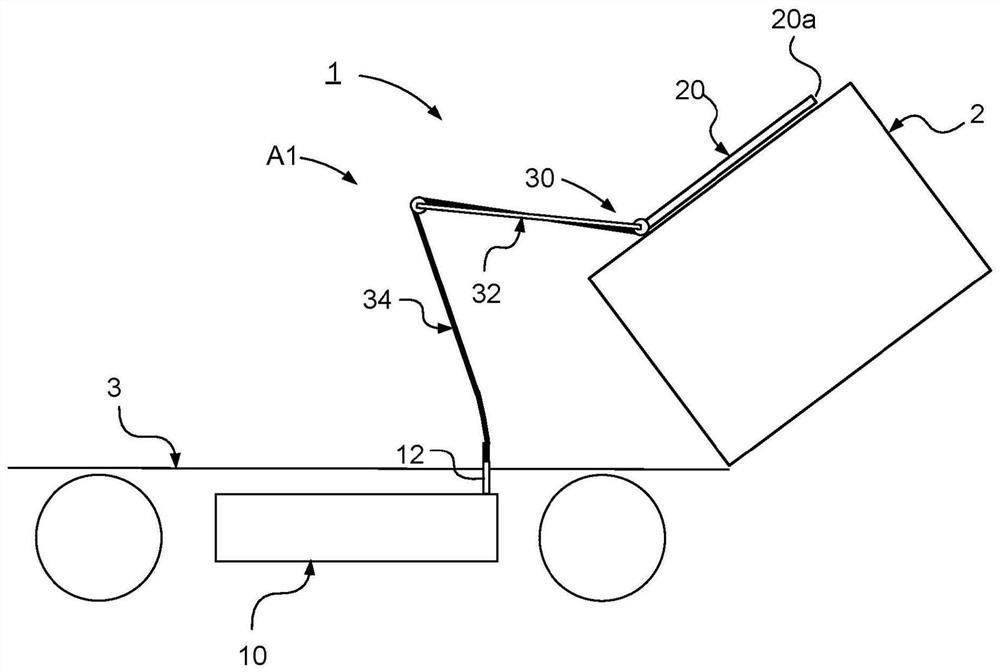

[0032] Figure 1a Schematically shows a side view of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com