Tool for installing or removing wire thread inserts and method of manufacture

A technology for wire threaded inserts and tools, applied in the manufacture of tools, screwdrivers, hand-held tools, etc., can solve the problems of material fatigue, maintenance costs, shorten tool life, etc., and achieve the effect of reducing mechanical stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

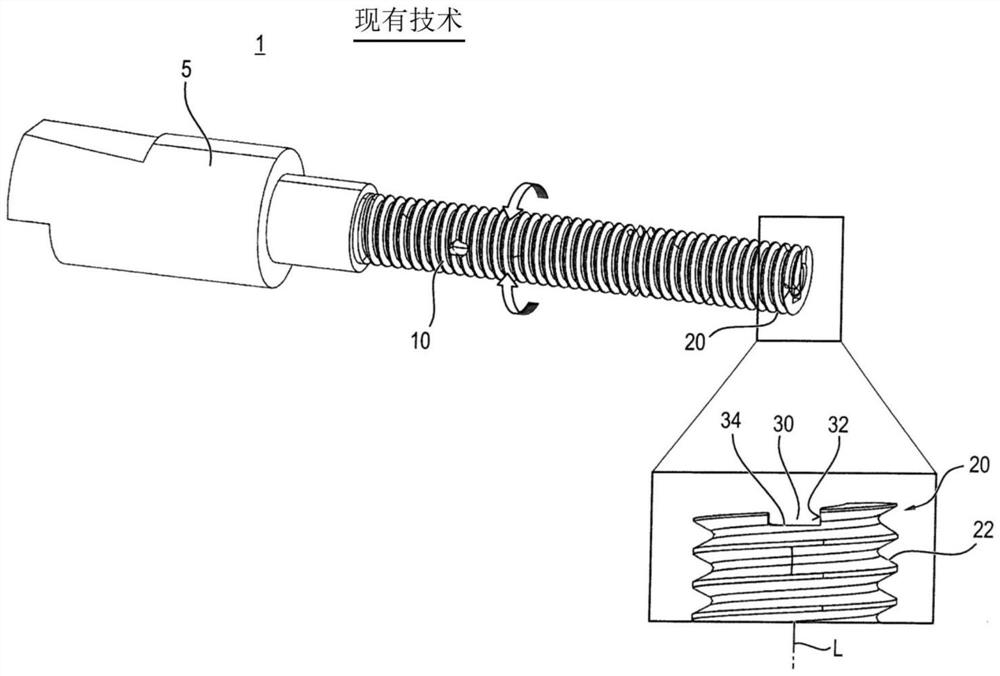

[0028] As mentioned above, various tools for installing or removing wire thread inserts are known in the prior art. figure 1 An example of such a tool 1 is shown. The tool 1 comprises a spindle body 10 which can be rotated automatically and / or manually by means of a drive 5 . figure 1 The drive part 5 is shown which can be fastened in a suitable chuck of the drive. For turning the tool 1 manually, a lever or arm (not shown) is preferably provided transverse to the longitudinal axis L of the tool 1 .

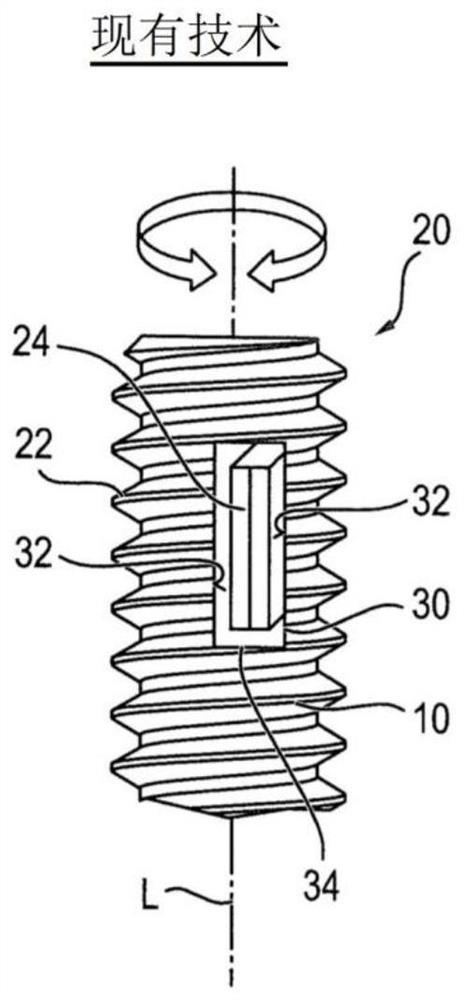

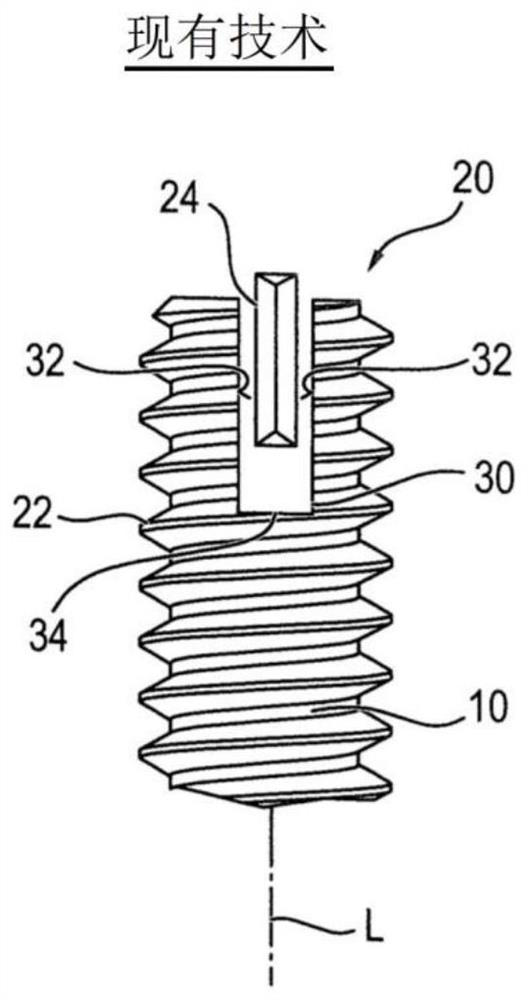

[0029] The spindle body 10 has a seat 20 for a wire threaded insert (not shown) at an end opposite to the drive portion 5 . Seat 20 can be in figure 1 See the partial enlargement in Fig.

[0030] The seat 20 includes threads 2 for turning or screwing on a wire thread insert, or a non-threaded face (not shown) for inserting a wire thread insert.

[0031] In the spindle body 10 there is generally provided an axial opening (not shown) in which a mounting insert (also not shown)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com