Vehicle cable filling and sealing method

A technology for cables and vehicles, which is applied in the field of cable potting for vehicles. It can solve problems such as open soldering of solder joints, short circuit of wire core welding, and affecting normal operation of the system, so as to improve reliability, reliable connection, and prevent external The effect of interference signal stringing in

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

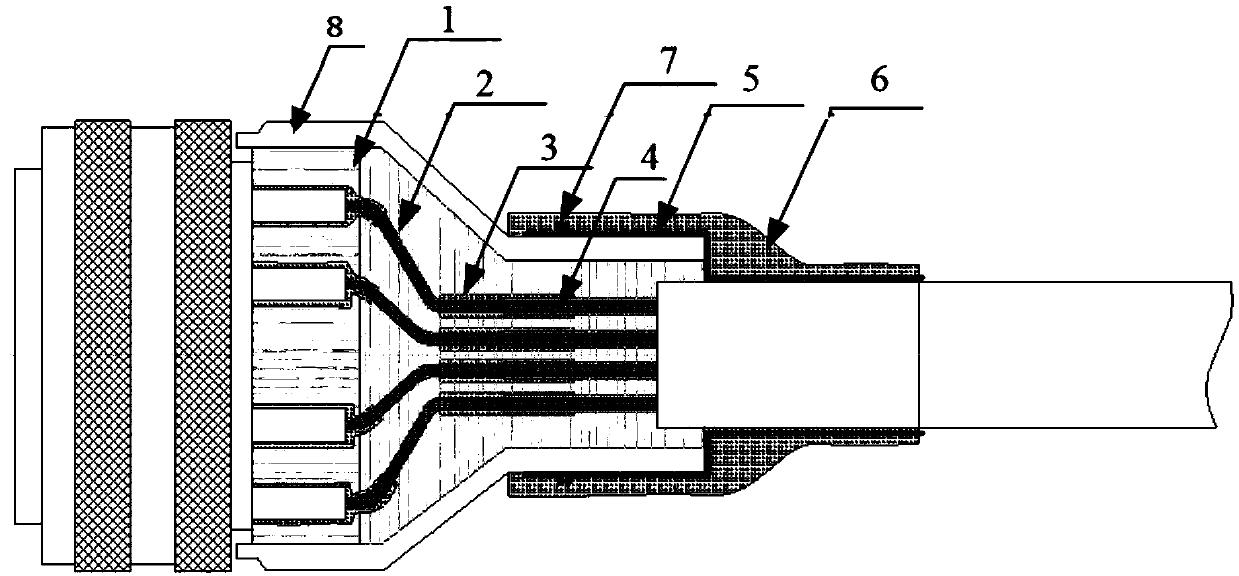

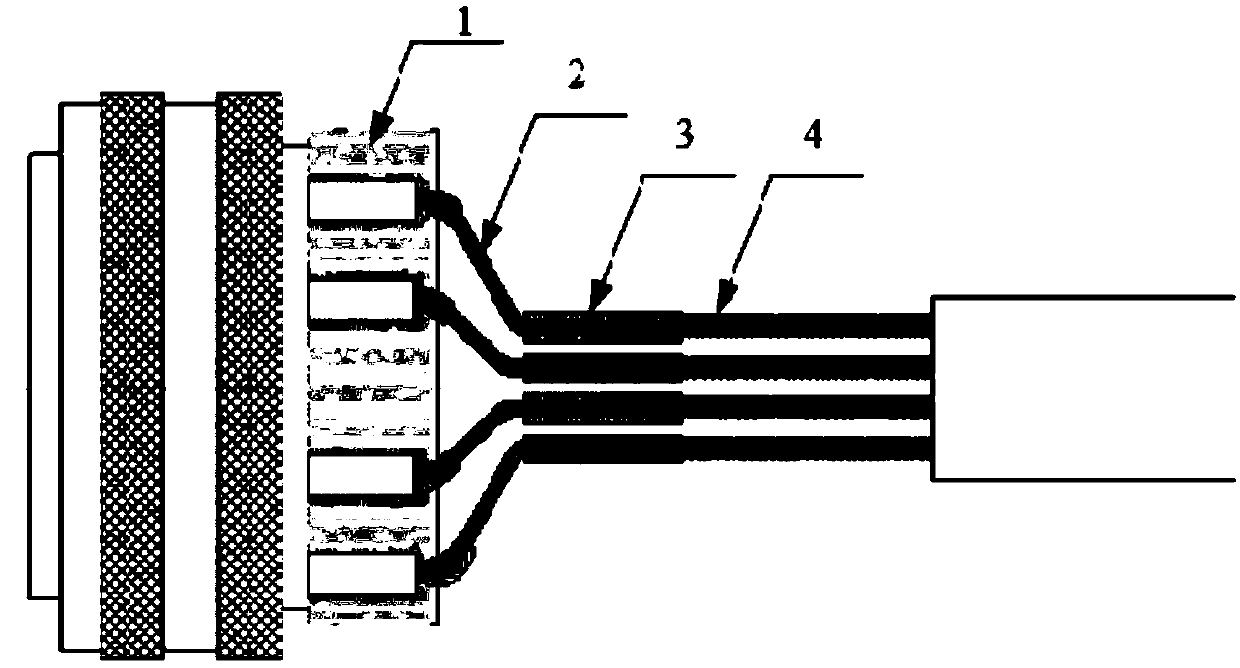

[0023] A kind of automotive cable potting method, such as figure 1 , 2 shown, including the following steps:

[0024] After the wire core 2 is welded, use the heat shrinkable tube 3 to heat shrink it, pour 704 adhesive 1 in the welding place, and solidify to form a protection for the solder joint, ensure the reliability of the connection, and make the connection place withstand a certain pulling force;

[0025] After the 704 adhesive 1 is completely cured, use the heat-shrinkable tube 3 to heat-shrink and fix the core 2 and the single-core wire shielding layer 4 to prevent the single-core wire shielding layer 4 from moving and being damaged, thereby puncturing the wire core 2 and causi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com