Bismuth phosphate/cerium phosphate composite lithium battery positive electrode material and preparation method

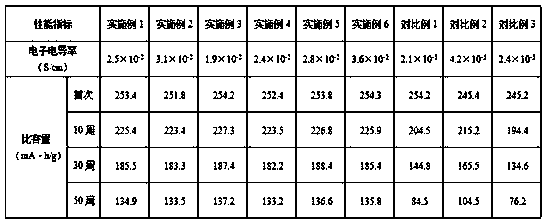

A battery cathode, cerium phosphate technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor conductivity, low specific capacity retention, unsatisfactory cycle performance of cathode materials, etc., to improve cycle performance and reduce energy. Barrier, the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Add graphene oxide into deionized water, ultrasonically disperse for 5.5 hours, then add reducing agent ascorbic acid, ultrasonically disperse for 26 minutes, seal and put in an oven to make a hydrogel, then wash with deionized water, and finally freeze-dry to prepare Obtain hydrophobic graphene airgel; in the preparation process of hydrophobic graphene airgel, graphene oxide 4 weight parts, deionized water 83 weight parts, ascorbic acid 13 weight parts; Heating temperature is 88 ℃, time is 14h; The freeze-drying temperature is -35°C and the time is 2.5 hours;

[0025] (2) Disperse the hydrophobic graphene airgel prepared in step (1) in deionized water, add bismuth nitrate pentahydrate and cerium nitrate hexahydrate, and keep ultrasonic dispersion, so that the precipitate produced by hydrolysis is adsorbed on the graphene air condensation In the micropores of the glue;

[0026] (3) Add diammonium hydrogen phosphate to deionized water to make a solution, then add it...

Embodiment 2

[0029] (1) Add graphene oxide into deionized water, ultrasonically disperse for 5 hours, then add reducing agent ascorbic acid, ultrasonically disperse for 22 minutes, seal and put in an oven to make a hydrogel, wash with deionized water, and finally freeze-dry to obtain Hydrophobic graphene airgel; in the preparation process of hydrophobic graphene airgel, 3 parts by weight of graphene oxide, 85 parts by weight of deionized water, and 12 parts by weight of ascorbic acid; the heating temperature is 88 ° C, and the time is 13 hours; freezing The drying temperature is -32°C and the drying time is 3 hours;

[0030] (2) Disperse the hydrophobic graphene airgel prepared in step (1) in deionized water, add bismuth nitrate pentahydrate and cerium nitrate hexahydrate, and keep ultrasonic dispersion, so that the precipitate produced by hydrolysis is adsorbed on the graphene air condensation In the micropores of the glue;

[0031] (3) Add diammonium hydrogen phosphate to deionized wate...

Embodiment 3

[0034] (1) Add graphene oxide into deionized water, ultrasonically disperse for 6 hours, then add reducing agent ascorbic acid, ultrasonically disperse for 28 minutes, seal and put in an oven to make a hydrogel, wash with deionized water, and finally freeze-dry to obtain Hydrophobic graphene airgel; in the preparation process of hydrophobic graphene airgel, 5 parts by weight of graphene oxide, 82 parts by weight of deionized water, and 13 parts by weight of ascorbic acid; the heating temperature is 92 ° C, and the time is 13 hours; freezing The drying temperature is -37°C and the drying time is 2 hours;

[0035] (2) Disperse the hydrophobic graphene airgel prepared in step (1) in deionized water, add bismuth nitrate pentahydrate and cerium nitrate hexahydrate, and keep ultrasonic dispersion, so that the precipitate produced by hydrolysis is adsorbed on the graphene air condensation In the micropores of the glue;

[0036] (3) Add diammonium hydrogen phosphate to deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com