A method for predicting the strength of hydration-damaged shale

A shale and strength technology, applied in the field of unconventional oil and gas exploration and development, can solve the problems of shale mechanical strength damage, shale softening, aggravating the difficulty of effective support of deep shale, and achieve the goal of improving work efficiency and rapid prediction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] figure 1 A flow chart of a method for predicting the strength of hydration-damaged shale is provided for the embodiment of the present invention, such as figure 1 As shown, the method of the present embodiment includes the following steps:

[0044] S1: Prepare standard rock samples of the target shale block: prepare N standard rock samples of the target shale block, select one of the standard rock samples without soaking treatment, and soak the other N-1 standard rock samples for t 1 , t 2 ···t n-1 Specifically, considering the influence of shale anisotropy on rock strength and deformation, samples should be taken in the same direction when preparing standard rock samples in the target shale block, and water should be avoided during the processing of standard rock samples, and standard rock samples should not be used during testing. Hydration occurs before. Specifically, the soaking device is as shown in the accompanying drawings figure 2 As shown, the soaking dev...

Embodiment 2

[0063] Taking a certain shale block as an example below, the implementation method of the present invention will be further described in detail, as follows:

[0064] According to step S1, prepare 5 standard rock samples of the target shale block, 1 standard rock sample is not soaked in water, and the remaining 4 standard rock samples are soaked in water for 3 days, 5 days, 10 days and 20 days respectively .

[0065] According to step S2, it is obtained that the closure pressure of the block is 70MPa. After drying the soaked standard rock samples, a triaxial mechanical test is carried out under a confining pressure of 70MPa to obtain the rock elastic modulus E of each standard rock sample. n , Poisson's ratio v n , internal friction angle The measurement results are shown in Table 1.

[0066] Table 1 Triaxial mechanical test parameter list

[0067]

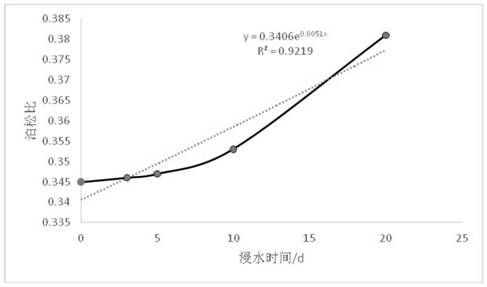

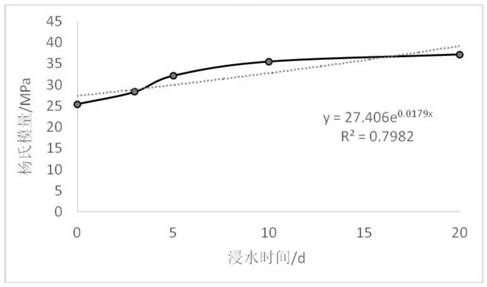

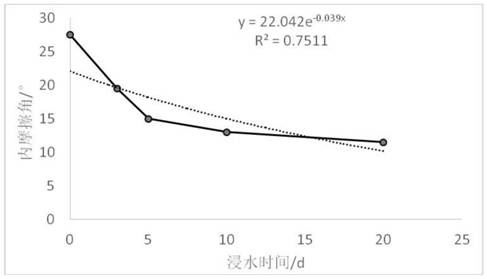

[0068] According to step S3, utilize the result of triaxial rock mechanics experiment, obtain Poisson's ratio-immersion t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com