Fabricated beam-column lead extrusion type energy dissipation joint

An extruded and assembled technology, which is applied in the direction of building types, protected buildings/shelters, building components, etc., can solve the problems of poor reliability of dry connections, achieve clear energy consumption principles, simple node forms, reduce The effect of small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

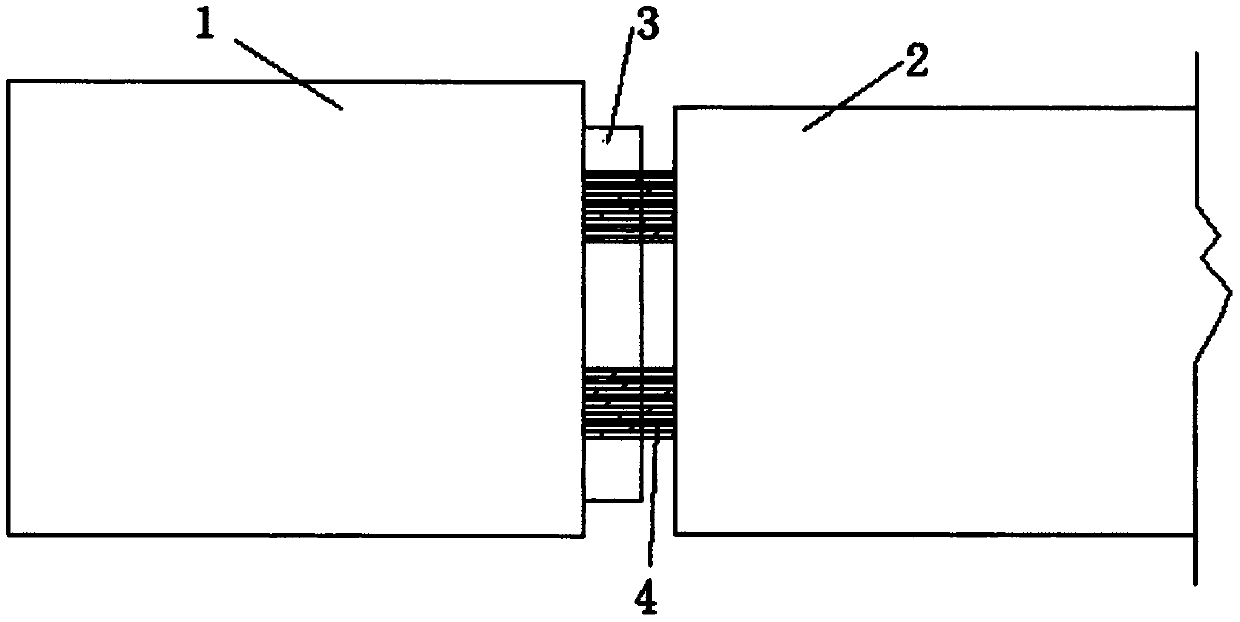

[0021] The invention provides an assembled beam-column lead extrusion type energy dissipation node, such as figure 1 As shown, it includes a precast concrete column 1 and a precast concrete beam 2; a steel plate 3 is preset on the outside of the precast concrete column 1, and a lead block 4 is arranged on the steel plate 3, and the precast concrete column 1 is fixedly connected to the precast concrete beam 2 through the steel plate 3. The lead block 4 is a rectangular block structure, two lead blocks 4 are arranged on the steel plate 3 , and the lead block 4 is located between the prefabricated concrete beam 2 and the steel plate 3 . The steel plate 3 and the prefabricated concrete beam 2 are fixed by riveting.

Embodiment 2

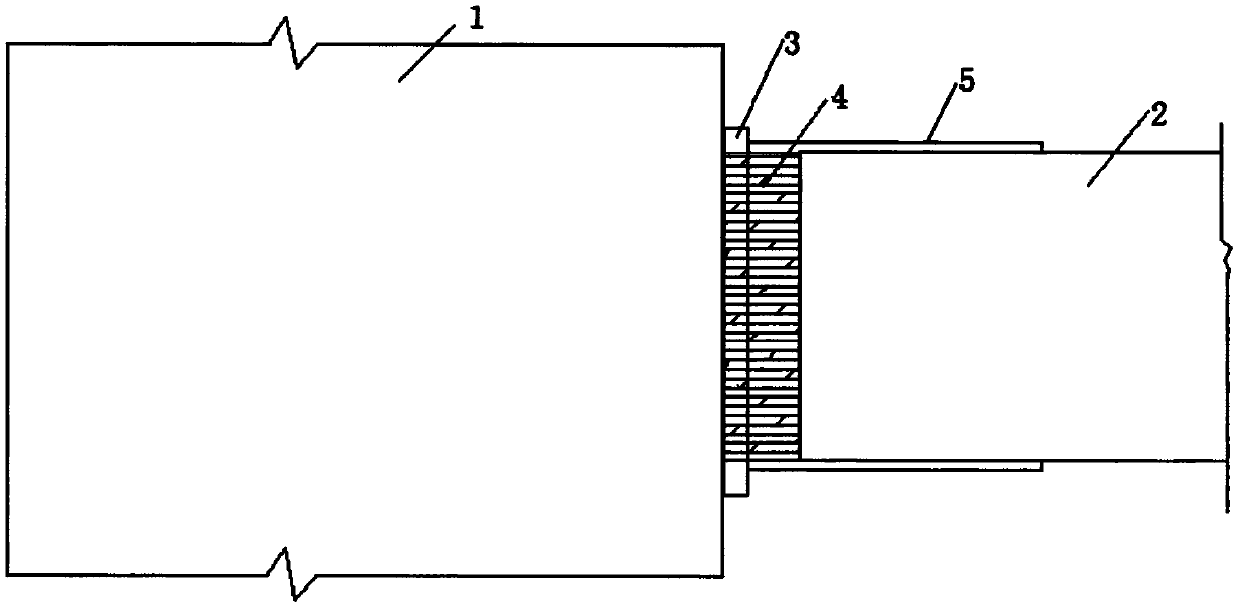

[0023] This embodiment is based on the structural changes and further improvements made on the basis of Embodiment 1. On the basis of Embodiment 1, such as figure 2 As shown, the lead block 4 is changed to a cuboid structure, and a lead block 4 is provided on the steel plate 3, so that the processing is more convenient and the force is more uniform. The lead block 4 is located between the precast concrete beam 2 and the steel plate 3 . The upper and lower ends of the steel plate 3 are respectively provided with a steel side plate 5, and the end of the precast concrete beam 2 close to the precast concrete column 1 is located between the two steel side plates 5, and the precast concrete beam 2 and the steel side plate 5 are respectively fixedly connected, The firmness of the connection between the precast concrete beam 2 and the precast concrete column 1 is further improved, which is safe and reliable.

[0024] When there is an earthquake or strong wind, the two ends of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com