Preparation method and application of barrier hydrophobic paper-based paint

A coating and paper-based technology, applied in the field of preparation of barrier hydrophobic paper coatings, can solve the problems of environmental pollution, complex operation process, toxic and harmful organic solvents, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

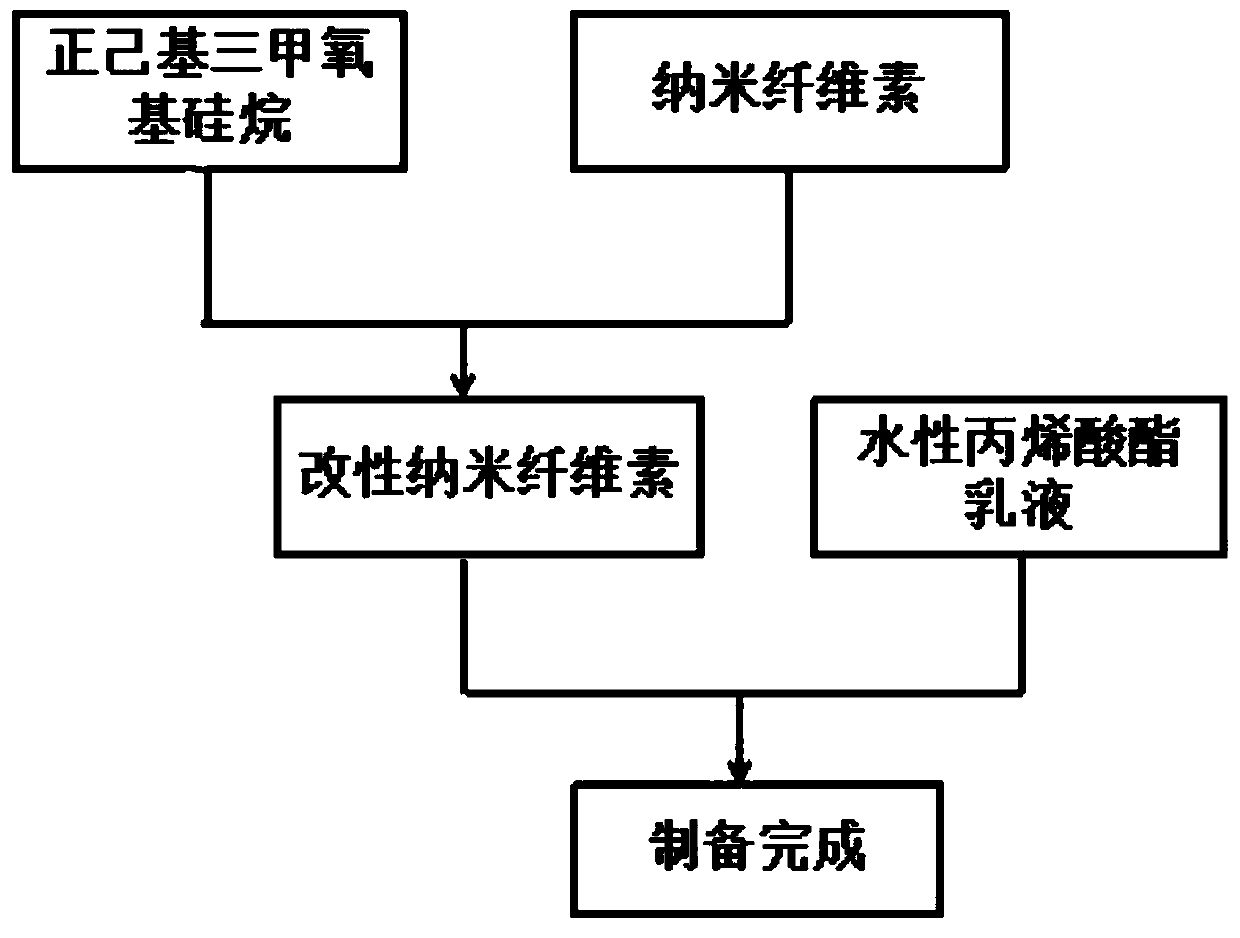

[0048] see figure 1 , the preparation method of a kind of barrier hydrophobic paper-based coating provided by the invention, it comprises the following steps:

[0049] (1) Preparation of modified nanocellulose:

[0050] (1.1) Prepare the raw materials of following components according to weight percentage:

[0051] Nanocellulose fibers: 5-40%

[0052] n-Hexyltrimethoxysilane: 20-60%

[0053] Alcohol solvent: 15-30%

[0054] Water: 10-25%;

[0055] (1.2) Preparation of hydrolyzate: first stir the alcohol solvent and water at high speed, when heated to a certain temperature, add n-hexyltrimethoxysilane, condense and reflux, react at constant temperature, the speed of high-speed stirring is 800-1500 rpm, heat The temperature is 30-80°C, and the constant temperature reaction time is 2-5 hours to obtain a hydrolyzate;

[0056] (1.3) Preparation of modified nanocellulose: After step (1.2) is completed, add nanocellulose fibers dropwise to the above solution, then start the mag...

Embodiment 2

[0088] Present embodiment is substantially the same as embodiment 1, and the weight percent of its concrete component is:

[0089] Modified Nanocellulose: 16.7%

[0090] Water-based acrylate emulsion: 83.3%;

[0091] The modified nanocellulose described therein comprises the following components by weight percentage:

[0092] Nanocellulose fibers: 16%

[0093] n-Hexyltrimethoxysilane: 48%

[0094] Alcohol solvent: 15%

[0095] Water: 21%;

[0096] The finished product of the barrier hydrophobic paper-based coating includes the following components in weight percent: 2.7% of nanocellulose fibers, 8.0% of n-hexyltrimethoxysilane, 2.5% of isopropanol, 3.5% of water, and 83.3% of pure acrylic emulsion.

[0097] The specific steps are: first stir 2.5% isopropanol and 3.5% water at a high speed, and when heated to a certain temperature, add 8.0% n-hexyltrimethoxysilane, condense and reflux, and keep the temperature constant For the reaction, the rotating speed of the high-spee...

Embodiment 3

[0106] The method and product provided in this embodiment are basically the same as those in Examples 1 and 2, the difference being that the weight percent of its components is:

[0107] Modified Nanocellulose: 9.1%

[0108] Water-based acrylate emulsion: 90.9%;

[0109] The modified nanocellulose described therein comprises the following components by weight percentage:

[0110] Nanocellulose fibers: 10%

[0111] n-Hexyltrimethoxysilane: 40%

[0112] Alcohol solvent: 26%

[0113] Water: 24%;

[0114] The finished product of the barrier hydrophobic paper-based coating includes the following components in weight percent: 1.5% of nanocellulose fiber, 4.3% of n-hexyltrimethoxysilane, 1.4% of isopropanol, 1.9% of water, and 90.9% of pure acrylic emulsion.

[0115] The specific steps are: first stir 1.4% isopropanol and 1.9% water at high speed in parts by mass, and then add 4.3% n-hexyltrimethoxysilane in parts by mass when heated to a certain temperature, condense and reflux, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com