A preparation method of solid oxygen particles with slow oxygen release function

A technology of oxygen granules and slow-release oxygen, which is applied in chemical instruments and methods, aerobic process treatment, sustainable biological treatment, etc., can solve the problems of sudden aerobic environment and the failure of aerobic microorganisms to be cultivated, so as to ensure long-term effect High performance, strong practicability and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: Preparation of slow-release oxygen particles

[0024] 1. Prepare biochar by vacuum pyrolysis, air-dry the collected rice straw and grind it so that the initial size is less than 0.25mm, then conduct high-temperature pyrolysis in a tube furnace at 350°C for 2 hours with nitrogen gas, and use 0.1mol / Wash with L HCl and ultrapure water until neutral, dry at 105°C, grind, and filter with a 0.25mm sieve to obtain the initial biochar material.

[0025] 2. Calcinate and grind 0.2mg of clay and 1mg of diatomaceous earth at 500°C and mix them with 0.3mg of ferrous sulfate powder to obtain mixture A; Mix 1 mg of the powder with 0.2 mg of biochar evenly, mix with 0.3 mg of polyvinylpyrrolidone solution (PVP, 3%) and stir thoroughly to obtain a mixture B; add the mixture B to the mixture A, and use a rotary press The tablet machine performs tablet compression to obtain the solid oxygen particles to be prepared.

Embodiment 2

[0027] 1. Inject 1L of distilled water that has been boiled, sterilized and cooled down into a cylindrical reactor with a diameter of 10cm and a height of 15cm. Set up a stirring bar and seal it with a sealing plug. Put 0.2gNa into the reactor from the injection port 2 SO 3 and 0.05gCoCl 2 , close the dosing port, and remove the dissolved oxygen in the reactor. When the DO drops to 0mg / L and stabilizes for 0.5h, the next step of the experiment can be carried out.

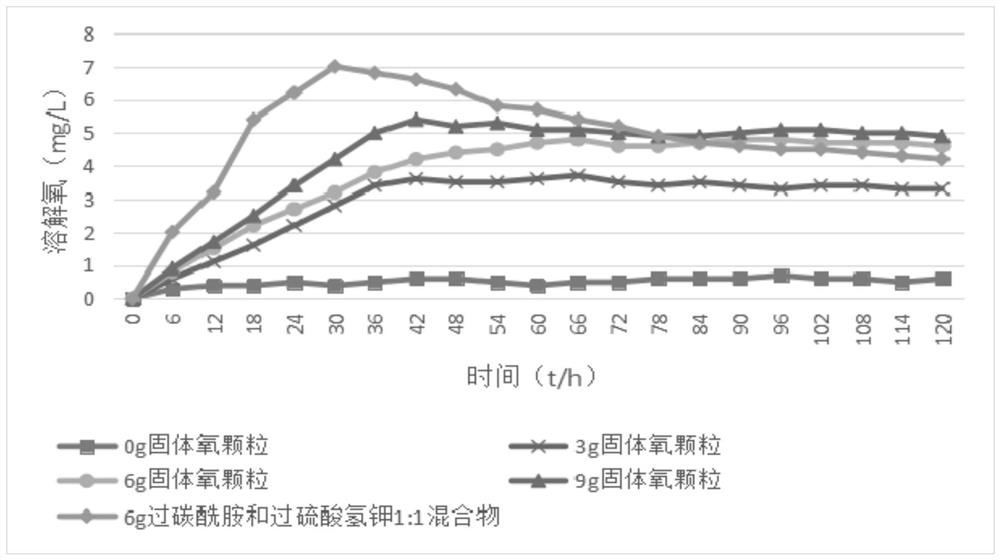

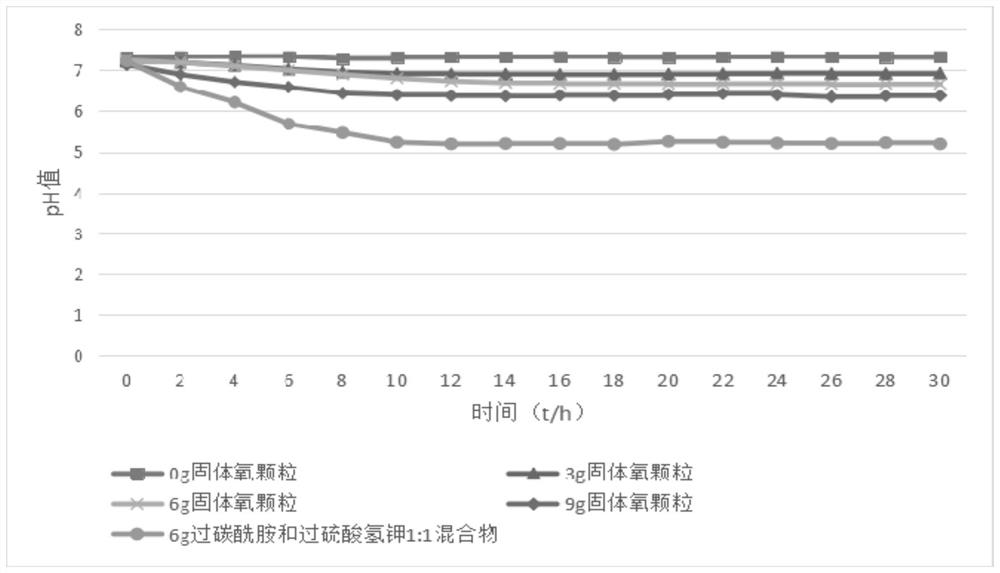

[0028] 2. Place the four reactors treated in the above step 1 on the workbench, add 0g, 3g, 6g, and 9g of the solid oxygen particles prepared in Example 1 to the above four reactors respectively, and then add the solid oxygen particles from the drug inlet Insert dissolved oxygen probe and pH probe.

[0029] 3. Test the dissolved oxygen and pH value in the four reactors every day.

[0030] The solid oxygen particles can slowly release oxygen for a long time, and the dosage of more than 6g in 1L of anaerobic water...

Embodiment 3

[0032] 1. Inject 1L of distilled water that has been boiled, sterilized and cooled down into a cylindrical reactor with a diameter of 10cm and a height of 15cm. Set up a stirring bar and seal it with a sealing plug. Put 0.2gNa into the reactor from the injection port 2 SO 3 and 0.05gCoCl 2 , close the dosing port, and remove the dissolved oxygen in the reactor. When the DO drops to 0mg / L and stabilizes for 0.5h, the next step of the experiment can be carried out.

[0033] 2. Place the three reactors treated in the above step 1 on the workbench, add 6g of solid oxygen particles, 6g of percarbamide and potassium persulfate mixture to the above two reactors respectively, and the other reactor Do not add as a blank group, and then insert a pH probe and a dissolved oxygen probe from the drug inlet.

[0034] 3. Check the pH value and dissolved oxygen in the three reactors every day.

[0035] Compared with the mixture of percarbamide and potassium hydrogen persulfate, the solid o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com