Non-stop roll-changing type die-cutting machine for winding and unwinding lithium battery positive and negative electrode base materials

A positive and negative electrode, lithium battery technology, applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the problem of time-consuming and laborious, affecting the efficiency of die-cutting, and no published patent documents have been found, so as to ensure the workshop environment. , The effect of saving roll change time and easy loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

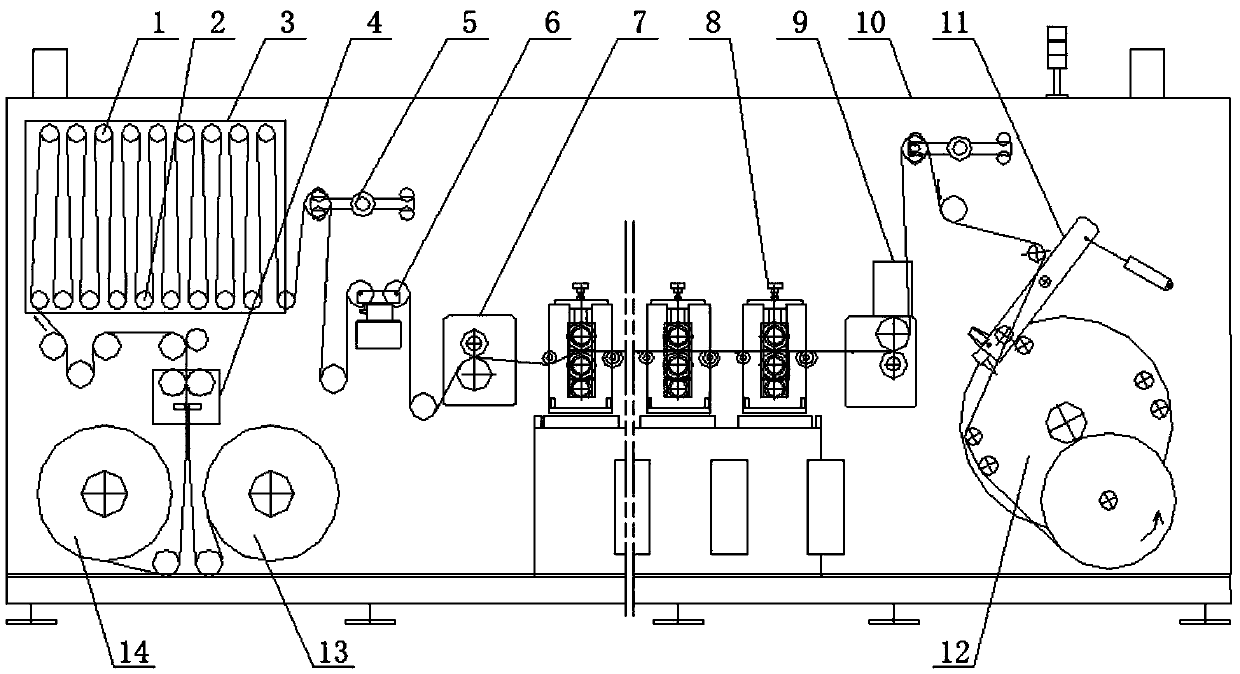

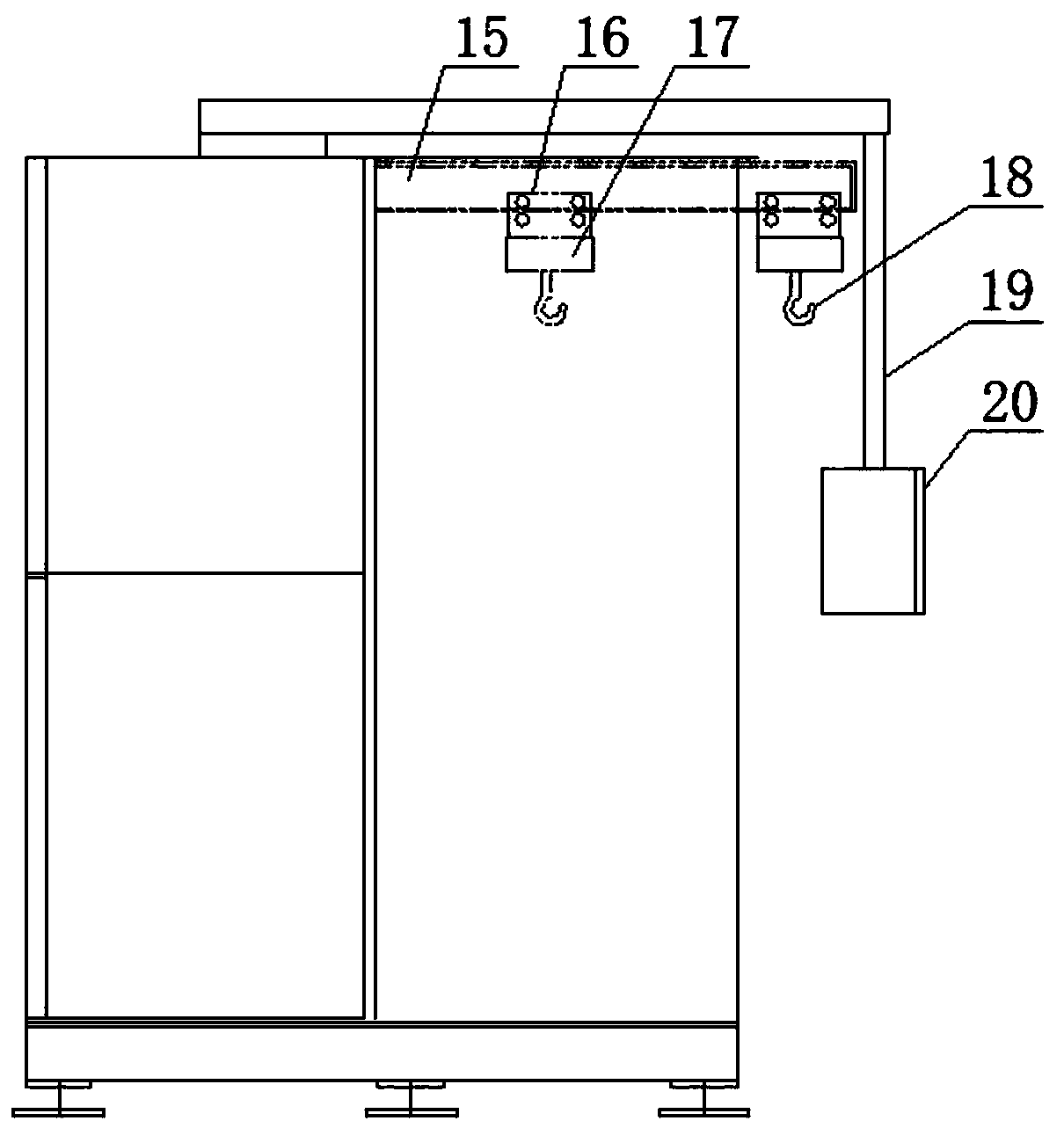

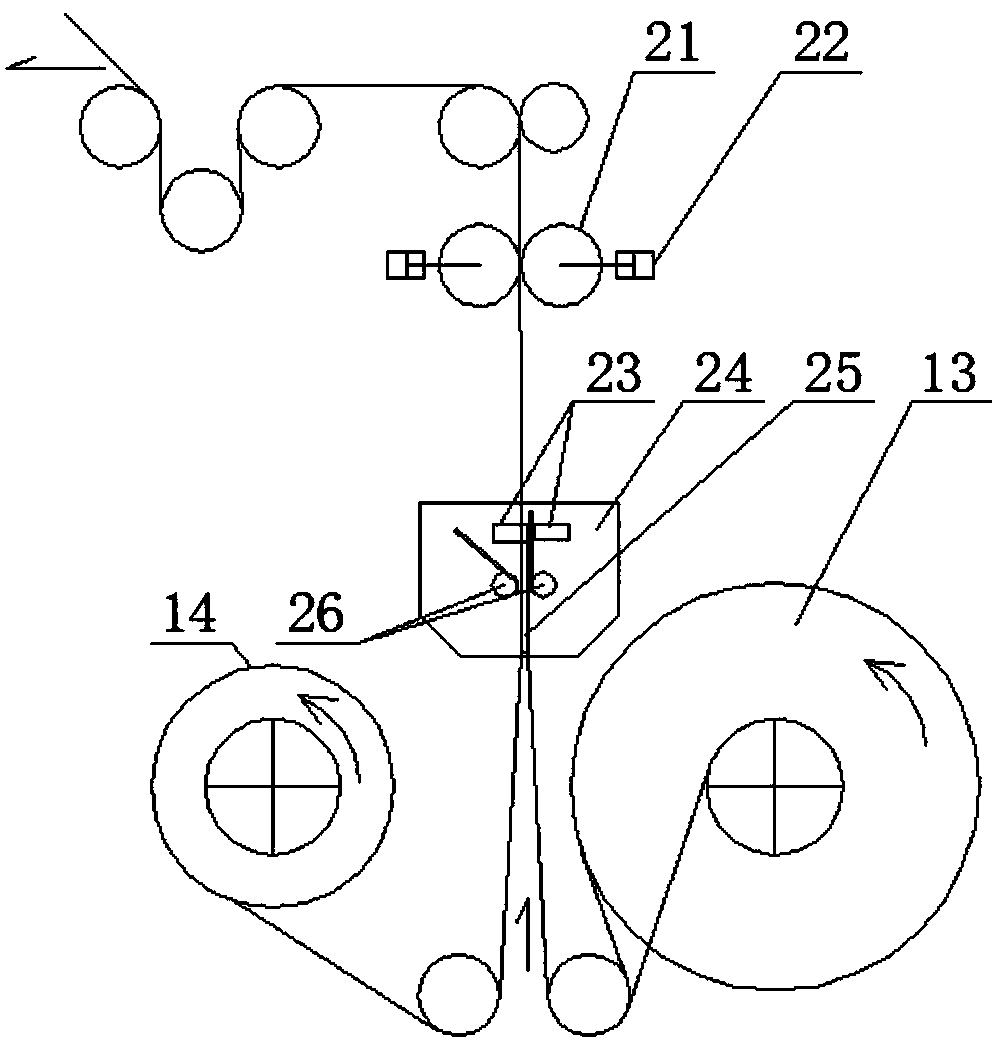

[0038] A non-stop reel-changing die-cutting machine for lithium battery positive and negative base materials. Material mechanism 4, material storage box 3, tension regulator 5, travel correction device 6, traction mechanism 7, die-cutting mechanism 8, constant speed material receiving mechanism 11, dust removal mechanism 9, bracket turntable 12, first rewinding shaft 45, second Two rewinding shafts 49 and the central control box 20 are installed with a material storage box, a zero-speed material receiving mechanism, and the first unwinding shaft and the second unwinding shaft arranged on the left and right from top to bottom at the discharging end of the frame. A tension regulator is installed on the rear frame of the zero-speed splicing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com