Shutdown reel-changing type round-press-round die cutting machine for lithium battery positive and negative substrate unwinding and winding

A positive and negative electrode, lithium battery technology, applied in the direction of winding strip, thin material processing, transportation and packaging, etc., can solve the hidden danger of the stability of energy storage index parameters, the improvement of lithium battery production efficiency has a bottleneck effect, production Long cycle and other problems, to achieve the effect of protecting the workshop environment and working environment, avoiding damage to the substrate coating density, and scientific and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below through specific examples. The following examples are only descriptive and not restrictive, and cannot limit the protection scope of the present invention.

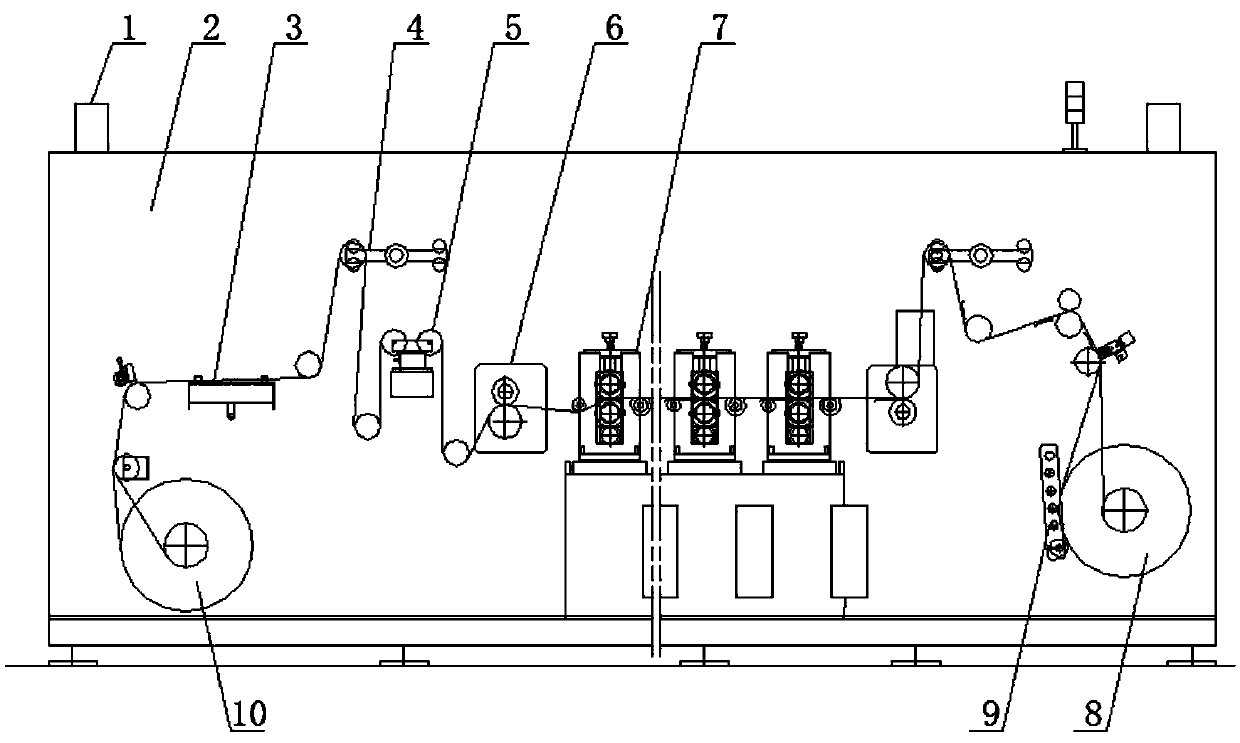

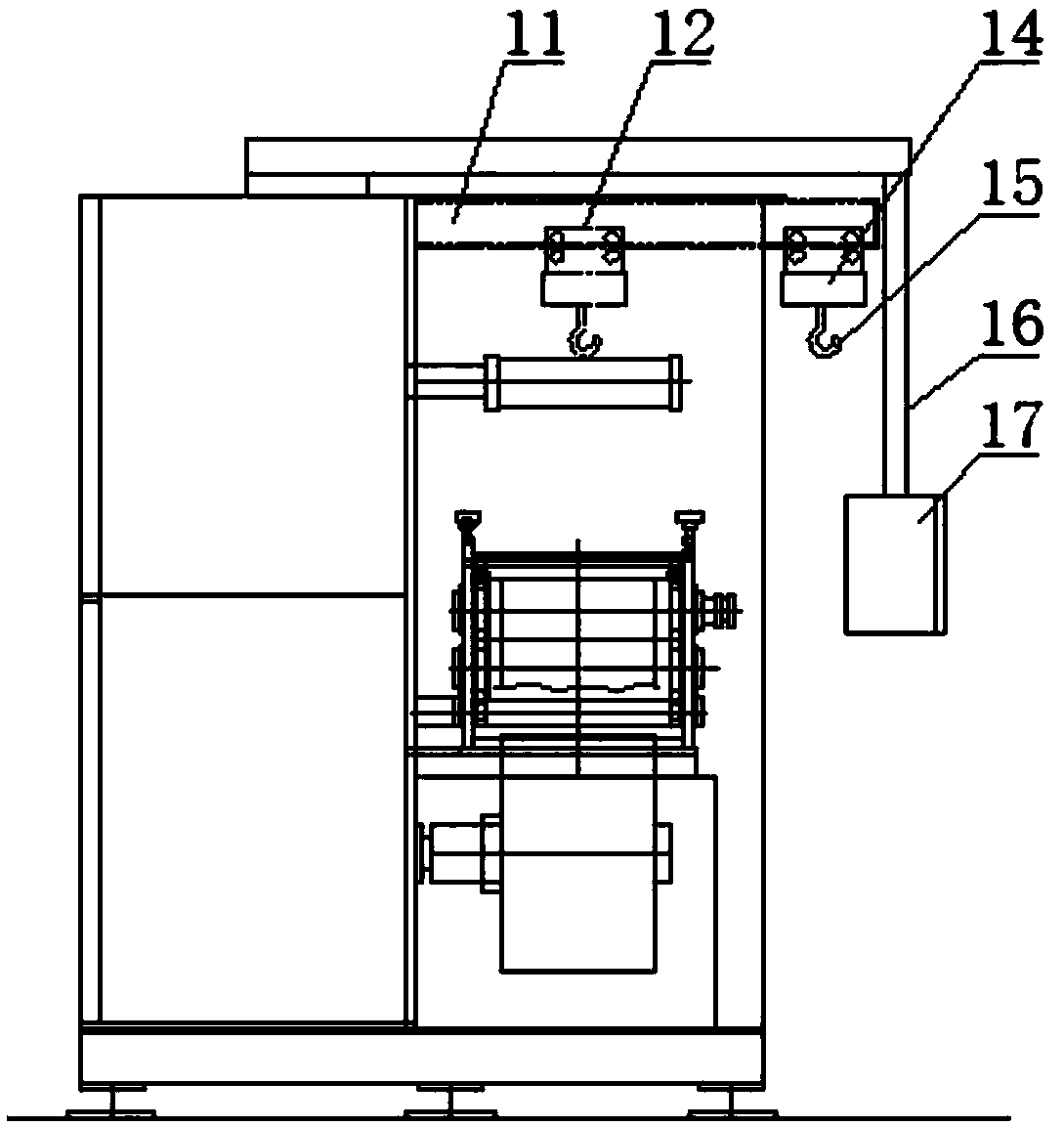

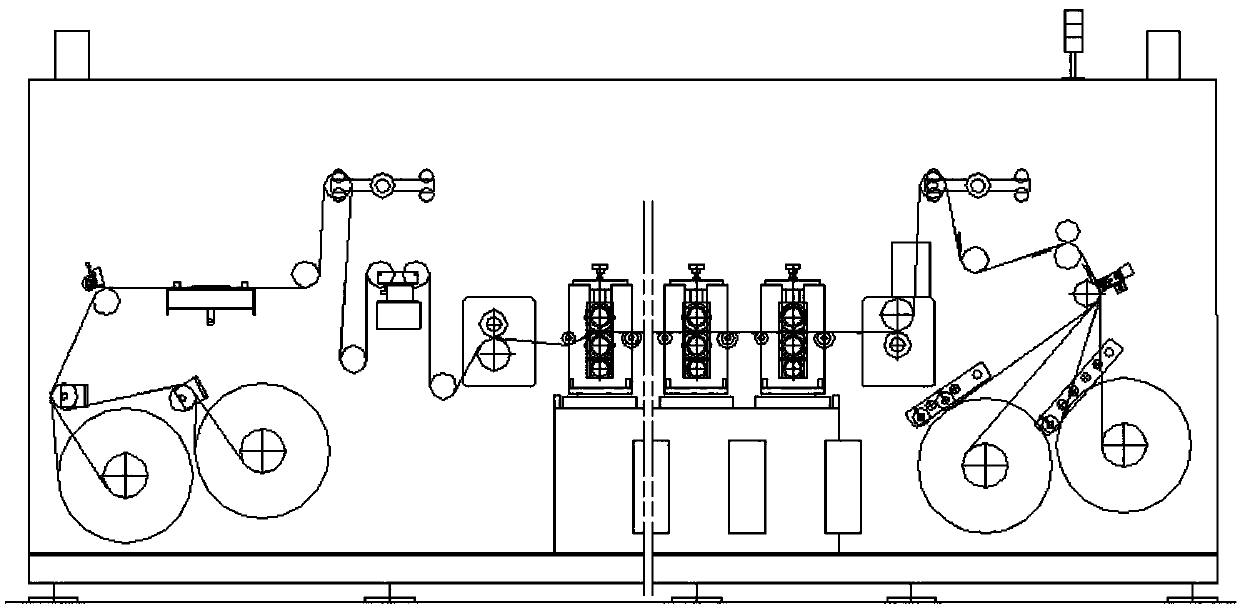

[0037] A shut-down roll-changing circular die-cutting machine used for charging and rewinding lithium battery positive and negative substrates. Its innovation lies in: including frame 2, unwinding shaft 10, material receiving mechanism 3, and tension regulator 4 , Traveling corrector 5, traction mechanism 6, die-cutting mechanism 7, split dust removal mechanism, combined dust removal mechanism, winding shaft 8 and central control box 17, on the frame from left to right are arranged with unwinding shaft, The material receiving mechanism, the tension regulator, the traveling rectifier, the traction mechanism, the die cutting mechanism, the traction mechanism, the tension regulator and the winding shaft, the separate dust removal mechanism is arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com