Cleaning roller brush of belt conveyor

A belt conveyor and wool roller technology, applied in conveyor objects, cleaning devices, transportation and packaging, etc., can solve problems such as inability to clean the belt, and achieve the effect of improving the effect and avoiding spillage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

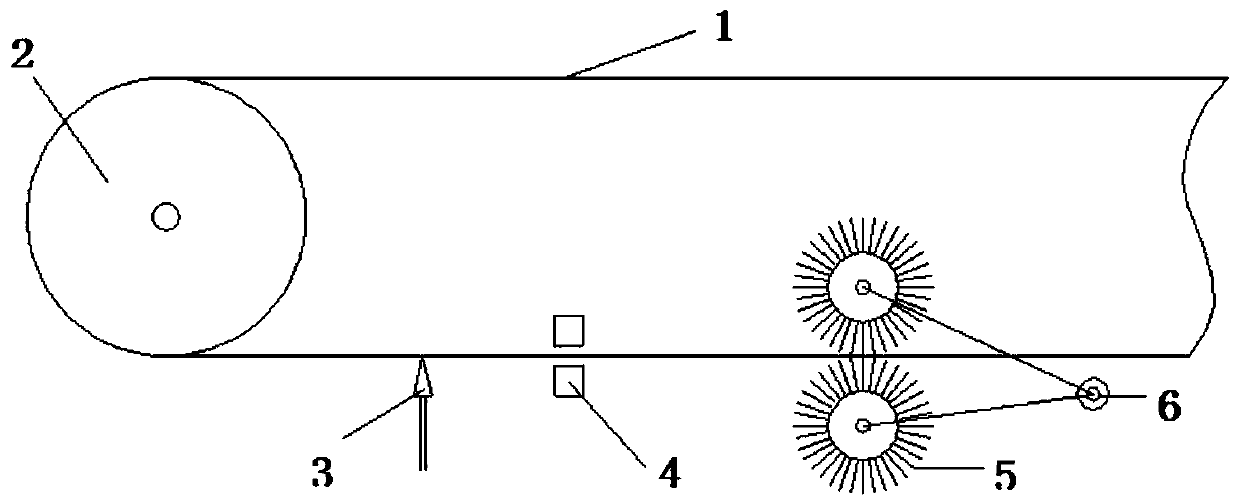

[0022] Such as figure 1 Shown, a kind of cleaning hair roller brush of belt conveyor, it comprises belt 1, driving roller 2, driven roller, scraper 3, dryer 4, hair roller brush 5, wherein scraper 3, dryer 4 , hair roller brush 5 are all arranged on the return journey of belt 1, and its sequence is scraper 3, dryer 4, hair roller brush 5 successively, and wherein, dryer 4 is provided with two, is used for drying belt 1 up and down. Dry, two hair roller brushes 5 are provided, including an upper hair roller brush and a lower hair roller brush, both of which have the same structure, and are driven by a motor 6 to rotate.

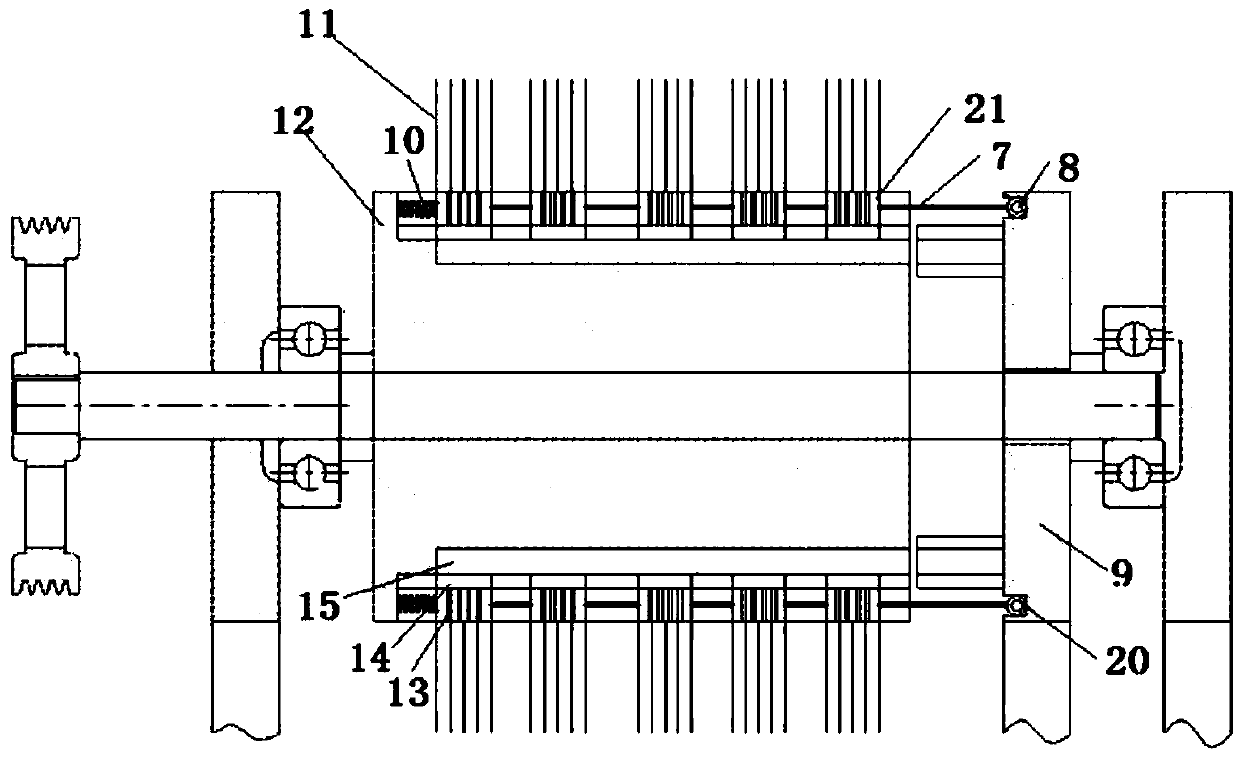

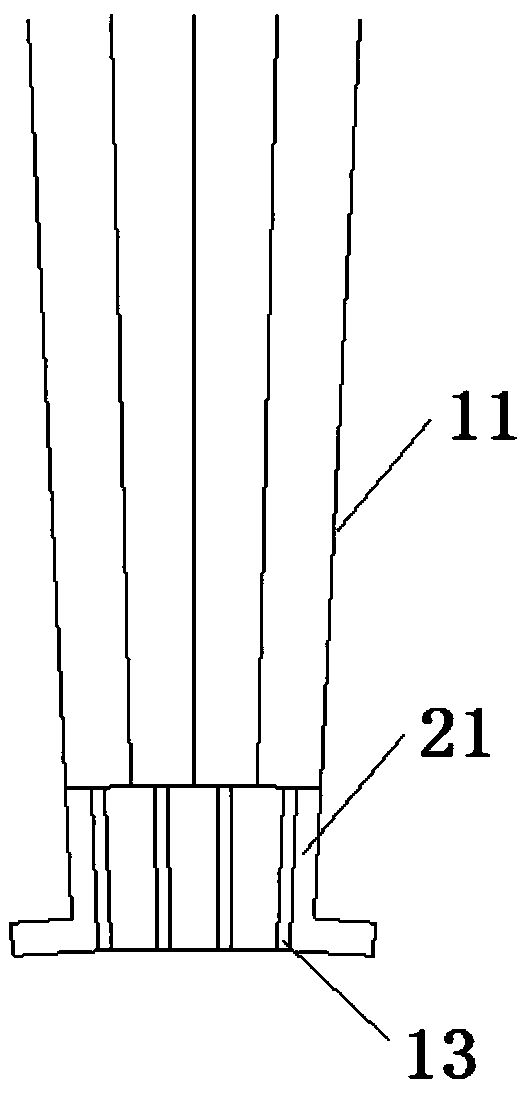

[0023] Such as Figure 2-3 As shown, the hair roller brush 5 includes bristles 11 and a rotating roller 12; wherein, the outer circumference of the rotating roller 12 is provided with a plurality of grooves arranged along the length of the rotating roller 12, and a hair brush block 21 is arranged in the groove, and the hair brush block 21 can slide back and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com