High-efficiency full-automatic tablet packaging machine

A packaging machine, fully automatic technology, applied in the field of pharmaceutical production and packaging, can solve the problems of packaging bags affecting the trimming process, packaging bag twisting and displacement, packaging machine stop working, etc., to improve the working conditions of workers, automatic and fast packaging, and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

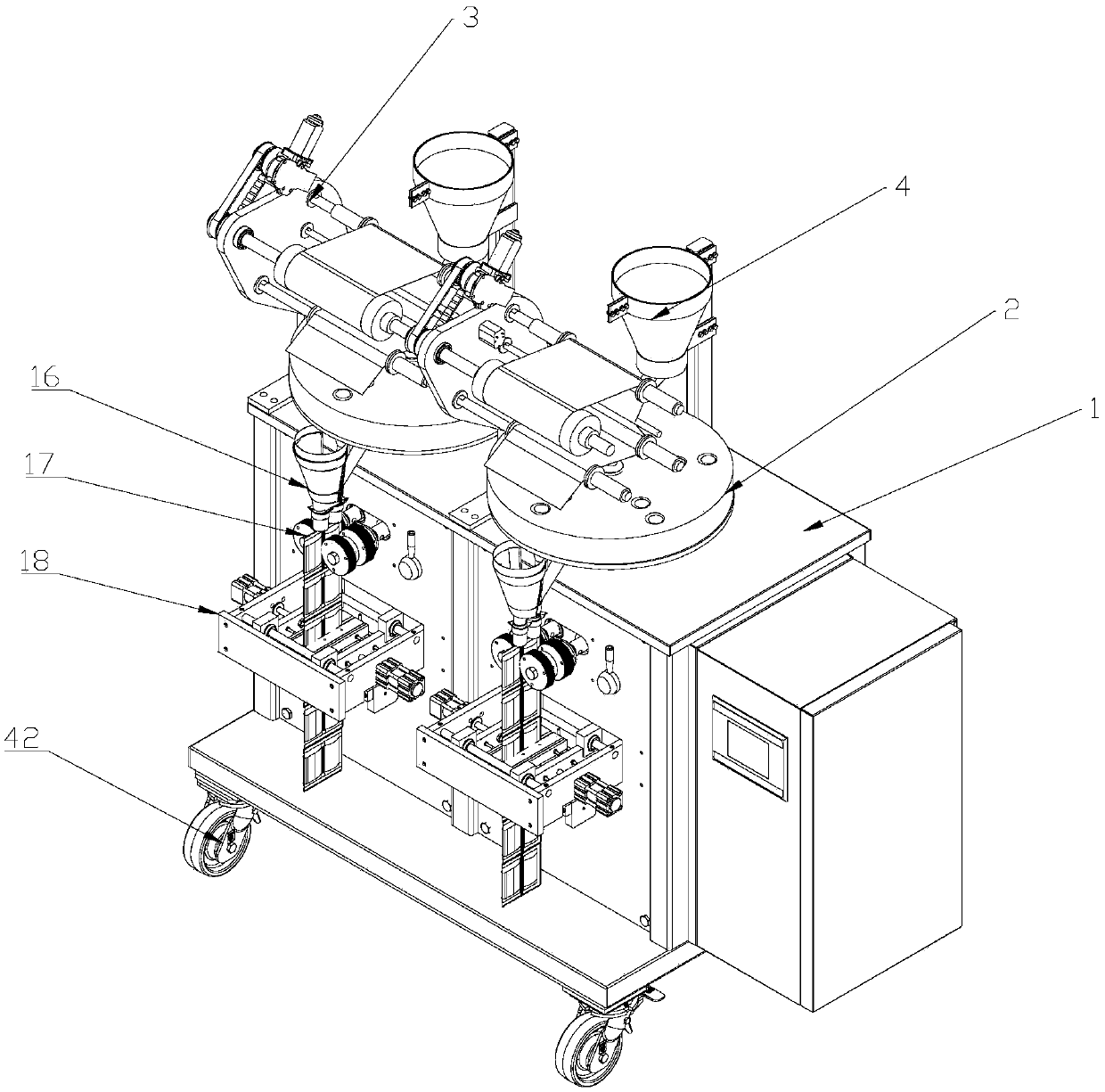

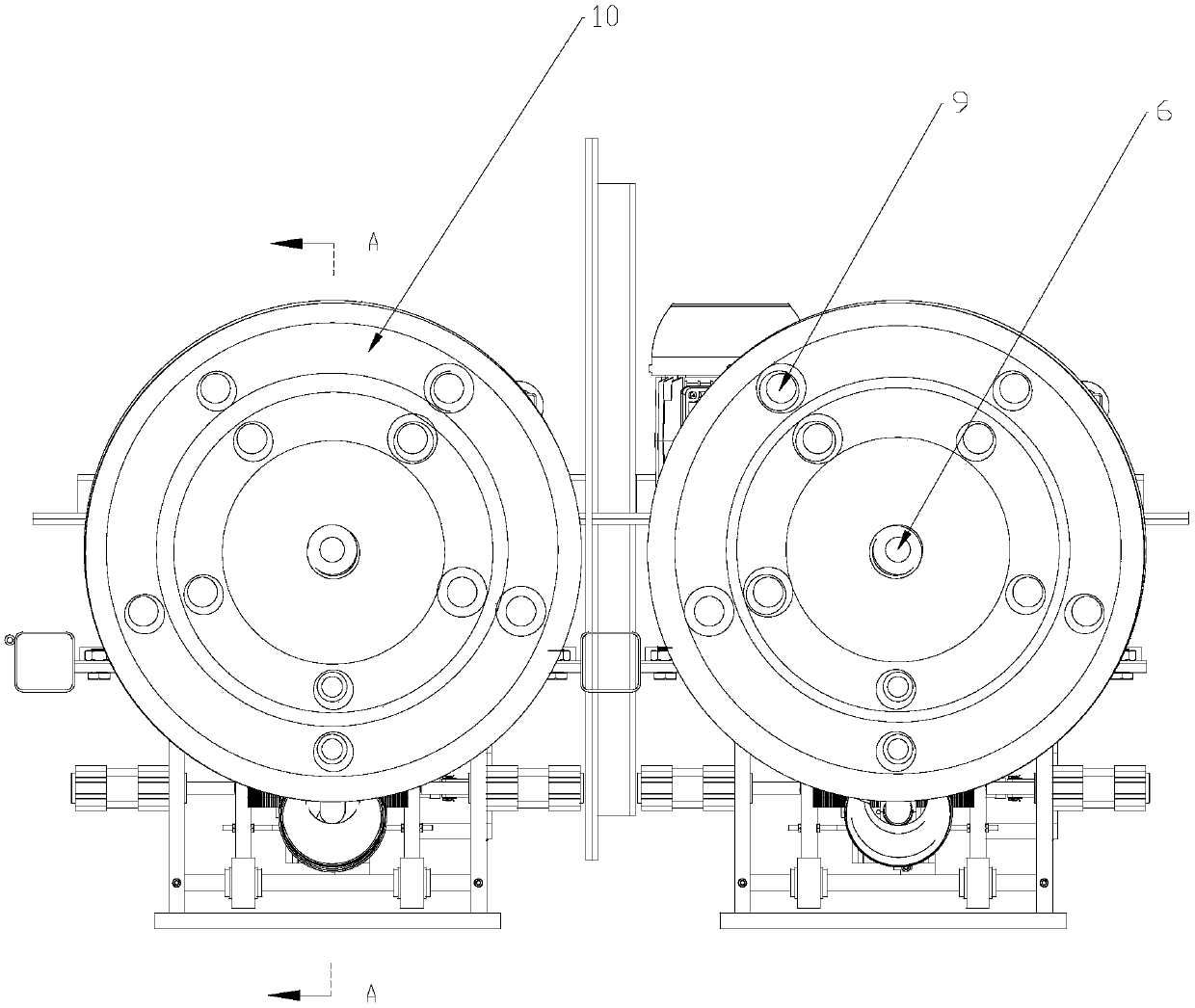

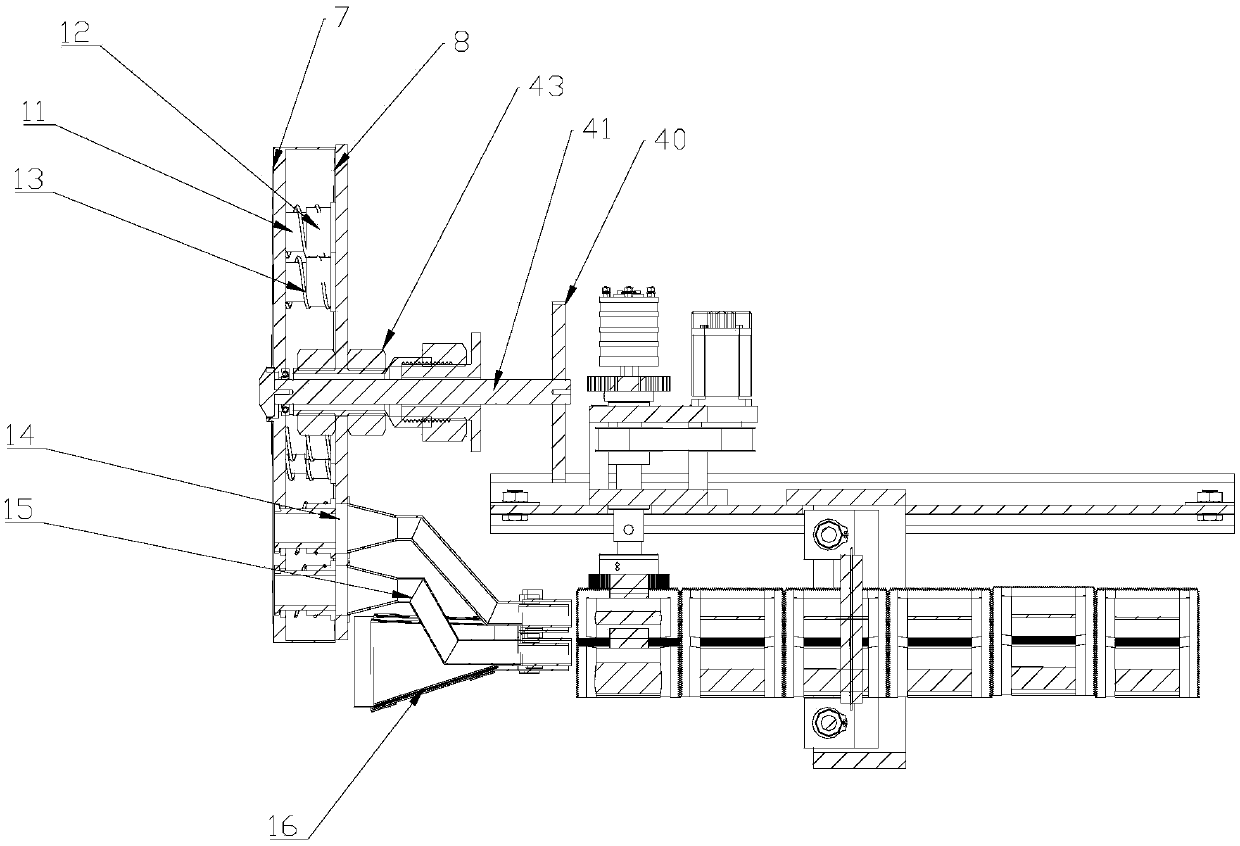

[0027] like Figure 1-5 As shown, a high-efficiency automatic tablet packaging machine includes a frame 1 with a built-in cavity, and two tablet delivery devices 2 and film delivery devices 3 are arranged on the frame 1. The tablet delivery device 2 Including a tablet storage funnel 4, two discharge holes are arranged at the bottom of the storage funnel 4, and the discharge holes are connected to the tablet rotating disk 6 by setting a conveying pipe 5, and the tablet rotating disk 6 It includes an upper rotating disk 7 and a lower fixed disk 8, five feed inlets 9 are arranged on the upper circumference of the upper rotating disk 7, and conveying pipe sliding grooves 10 are arranged on the upper circumference of the upper rotating disk 7, and the plurality of inlets The feed openings 9 are respectively placed in the sliding grooves 10 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com