Large container ship wing bridge block integrated construction method

A container ship, large-scale technology, applied in the direction of ship construction, ship parts, ship design, etc., can solve problems such as reasonable arrangement of unfavorable construction sites, difficult to guarantee accuracy requirements, waste of materials, etc., to increase operation safety, improve production efficiency, Avoid the effect of working at heights

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

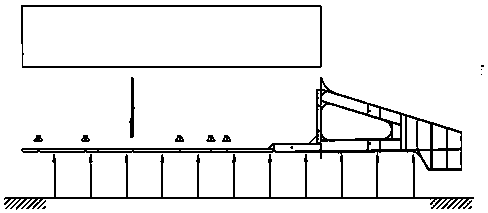

[0021] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

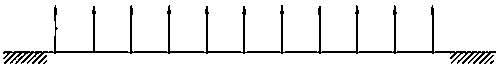

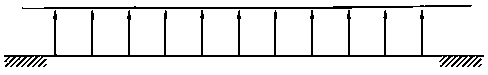

[0022] Such as Figure 1 to Figure 5 As shown, the method for segmentally integrated construction of large container ship wing bridge of the present invention comprises the following steps:

[0023] Step 1: Arrange the flat and general-purpose tire frame; arrange the flat and general-purpose tire frame for the anti-state integrated construction of the superstructure wing bridge segment and the driving deck segment of the large container ship on the general assembly platform. The tire frame is used for segmental jigsaw puzzle;

[0024] Step 2: Lay the steel plates in the reverse state; use the deck surface as the base surface, lay the steel plates used for the construction of the wing bridge section and the left and right deck sections of the driving deck section on the flat general tire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com