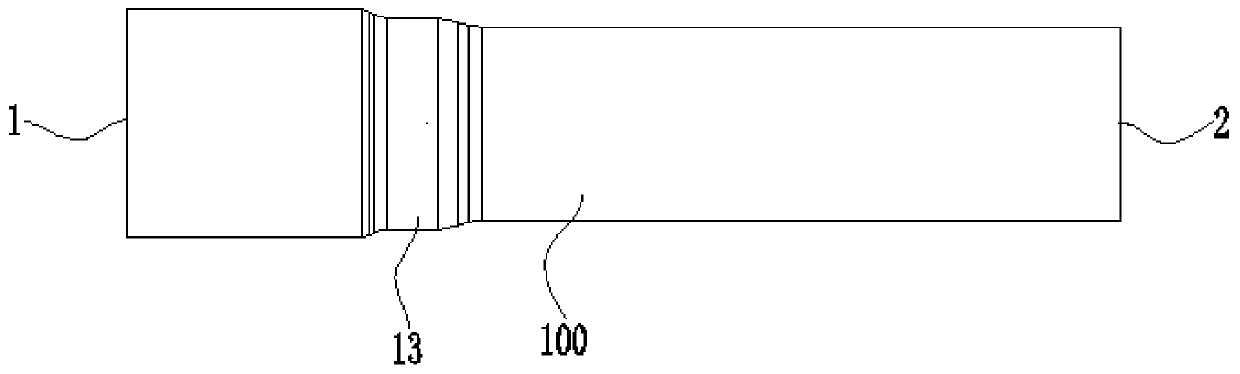

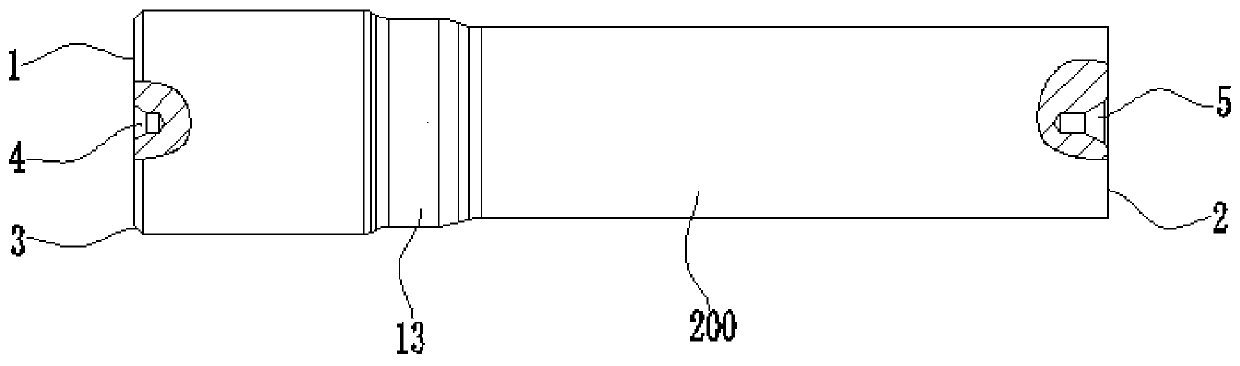

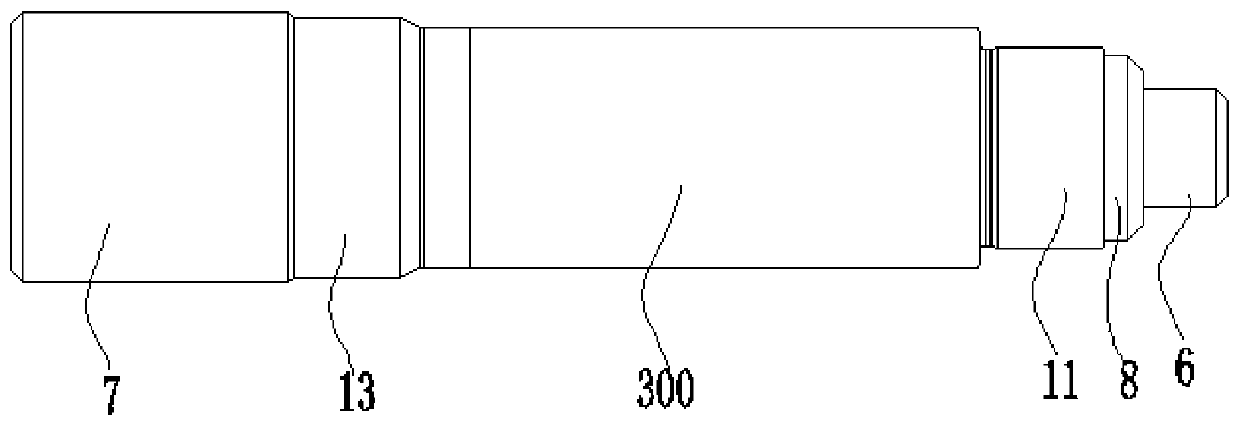

A washing machine shaft and its processing method

A processing method and washing machine technology, which can be applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of time-consuming and material-consuming washing machine shaft strengthening process, unstable production quality, and low processing accuracy, so as to reduce heat loss, The effect of saving raw materials and prolonging the life of the sealing position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063]In this implementation, when cutting the material, the 45 steel bar stock is selected, which has the following advantages: the surface of the 45 steel bar stock has less oxide layer, and reducing the grinding layer is also conducive to reducing the use of raw materials and reducing production costs; the length of the bar stock used It is 130mm and the diameter is 36mm. When grinding, since there is less oxide layer on the surface of the 45 steel bar, the linear velocity of the abrasive belt during rough grinding is 15m / s, the linear velocity of the abrasive belt during fine grinding is 25m / s, and the feed speed of the workpiece is 2m / min. The total depth is 0.12mm, which can make the surface of the ground bar material free of rust, which meets the requirements of use, and also reduces the grinding time, which is conducive to improving production efficiency; when dipping, spray the bar material with a hot water pipe to preheat The temperature of the bar material reaches 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com