Open type lock catch for automobile sliding door clamp

An open, locking technology, applied in the direction of building fastening devices, injection devices, construction, etc., can solve the problems that affect the installation and operation of the sliding door fixture, the linkage shaft 2 is stuck, easy to crack or even break, and reduce the The effect of rework cost, increase cleaning effect, and reduce maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and specific embodiments.

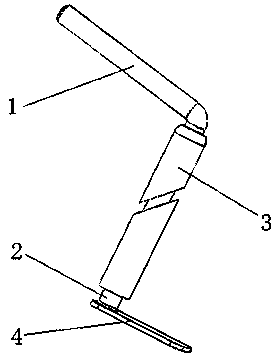

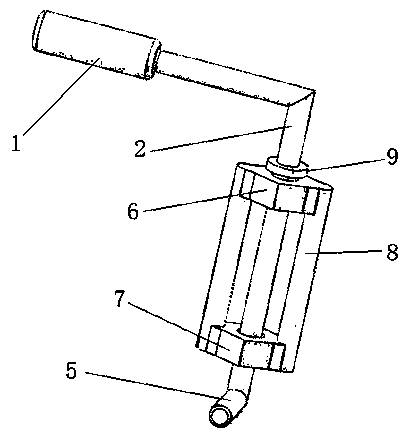

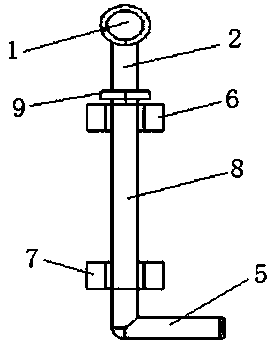

[0023] See attached figure 2 Attached Figure 5 , An open lock for automobile sliding door fixtures, including a rotating handle 1, a linkage shaft 2, a lock catch 5, a first support ring 6, a second support ring 7 and several support links 8; a rotating handle 1 One end is connected to one end of the linkage shaft 2, and the lock 5 is connected to the other end of the linkage shaft 2. The first support ring 6 and the second support ring 7 are provided with through holes in the middle, and the linkage shaft 2 penetrates the first support through the through holes The ring 6 and the second support ring 7; a number of support links 8 are respectively connected between the first support ring 6 and the second support ring 7 to form a shaft fixing seat sleeved on the linkage shaft 2.

[0024] The upper part of the linkage shaft 2 is provided with a flange 9. The li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com