Processing method and application of medicinal slices prepared from radix angelicae sinensis and salt

A processing method and technology of Guan Huangbai, applied in the processing field of Yanguan Huangbai decoction pieces, can solve the problems of failing to exert the optimal performance of equipment, low processing temperature, long processing time, etc., to improve product quality, shorten processing time, and improve product quality. good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

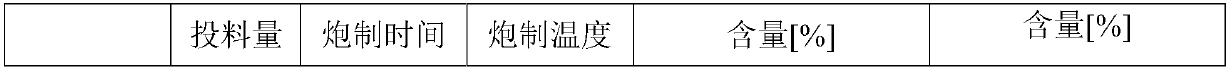

Embodiment 1

[0046] A processing method for decoction pieces of Yanguan Cortex Phellodendri, comprising:

[0047] Selection steps: Put the cork cork into clean plastic baskets in different sizes;

[0048] Washing steps: Spray Guan Phellodendron with drinking water until it is wet, and then moisten it for 12 hours;

[0049] Slicing step: cut the washed material into 10mm wide wire;

[0050] Drying step: place the sliced Cortex Phellodendri in a drying shed to dry naturally until the water content does not exceed 11%;

[0051] Classification steps: classify the dried Guan Phellodendron by size, which is biased towards processing;

[0052] Processing steps: shut off Cortex Phellodendron for every 100kg, use 2kg of salt, feed 8kg in each pot, set the temperature of the frying machine at 360°C, and fry for 16 minutes.

Embodiment 2

[0054] A processing method for decoction pieces of Yanguan Cortex Phellodendri, comprising:

[0055] Selection steps: Put the cork cork into clean plastic baskets in different sizes;

[0056] Washing steps: Spray Guan Phellodendron completely with drinking water until moistened, and moisten for 14 hours;

[0057] Slicing step: cut the washed material into 10mm wide wire;

[0058] Drying step: dry the sliced Cortex Phellodendri at 60°C in a dryer until the water content does not exceed 11%;

[0059] Classification steps: classify the dried Guan Phellodendron by size, which is biased towards processing;

[0060] Processing steps: shut off Cortex Phellodendron for every 100kg, use 2kg of salt, feed 8kg in each pot, set the temperature of the frying machine at 390°C, and fry for 12 minutes.

Embodiment 3

[0062] A processing method for decoction pieces of Yanguan Cortex Phellodendri, comprising:

[0063] Selection steps: Put the cork cork into clean plastic baskets in different sizes;

[0064] Washing steps: Spray Guan Phellodendron completely with drinking water until moistened, and moisten for 20 hours;

[0065] Slicing step: cut the washed material into 5mm wide wires;

[0066] Drying step: drying the sliced Cortex Phellodendri at 80°C with a dryer until the water content does not exceed 11%;

[0067] Classification steps: classify the dried Guan Phellodendron by size, which is biased towards processing;

[0068] Processing steps: shut off Phellodendron per 100kg, use 2kg of salt, feed 8kg in each pot, set the temperature of the medicine frying machine at 370°C, and fry the medicine for 14 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com