Processing method and application for coked grain sprout decoction pieces

A processing method and technology for grain buds, which are applied in the processing field of Jiaogu bud decoction pieces, can solve the problems of low production efficiency, long frying time and high processing temperature, and achieve the effects of good molded products, improved product quality and short processing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for processing burnt grain bud decoction pieces, comprising:

[0038] Rough selection step: unpack the grain buds and place them on the rough selection workbench, use a 18-mesh sieve to sieve the drug debris and pick out impurities;

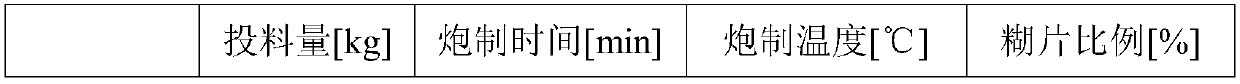

[0039] Processing steps: each pot feeds 20kg, set the temperature of the frying machine to 370°C, and the frying time is 15 minutes, fry until burnt brown, with a burnt aroma, and take out of the pot;

[0040] Fine selection step: use a sieve with a 24-mesh sieve to sieve the drug debris, pick out impurities and pasty flakes, and the product is obtained.

Embodiment 2

[0042] A method for processing burnt grain bud decoction pieces, comprising:

[0043] Rough selection step: unpack the grain buds and place them on the rough selection workbench, use a 18-mesh sieve to sieve the drug debris and pick out impurities;

[0044] Processing steps: each pot feeds 20kg, set the temperature of the frying machine to 350°C, and the frying time is 22min, fry until burnt brown, with a burnt aroma, and take out of the pot;

[0045] Fine selection step: use a sieve with a 24-mesh sieve to sieve the drug debris, pick out impurities and pasty flakes, and the product is obtained.

Embodiment 3

[0047] A method for processing burnt grain bud decoction pieces, comprising:

[0048] Rough selection step: unpack the grain buds and place them on the rough selection workbench, use a 18-mesh sieve to sieve the drug debris and pick out impurities;

[0049] Processing steps: each pot feeds 20kg, set the temperature of the frying machine at 360°C, and the frying time is 20min, fry until burnt brown, with burnt aroma, and take out of the pot;

[0050] Fine selection step: use a sieve with a 24-mesh sieve to sieve the drug debris, pick out impurities and pasty flakes, and the product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com