Method for preventing breakage in rice noodle sterilization process

A technology of process interruption and rice noodles, applied in food science and other directions, can solve the problems of reducing the broken rate of rice noodles, food safety risks, poor effect, etc., and achieve the effect of high application and promotion value, strengthening gel network, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

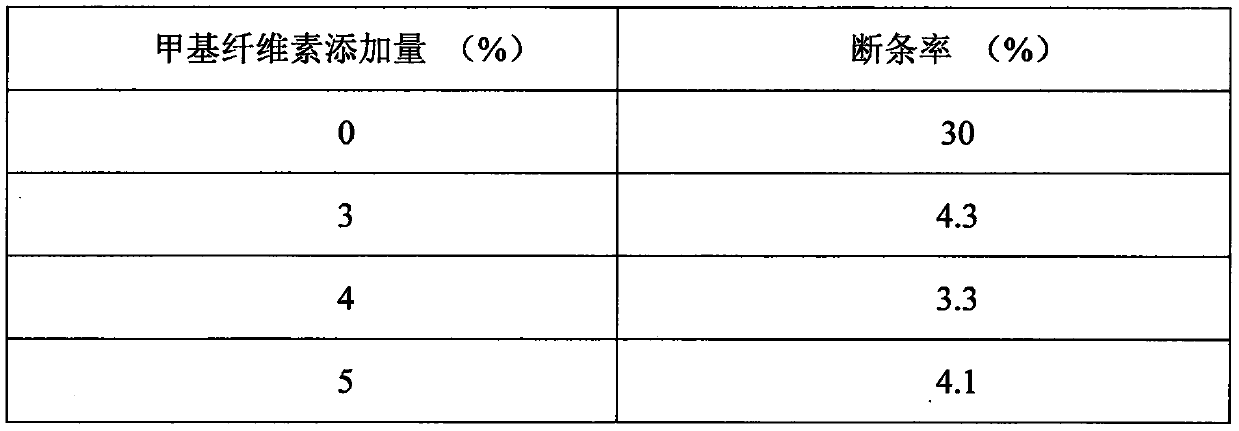

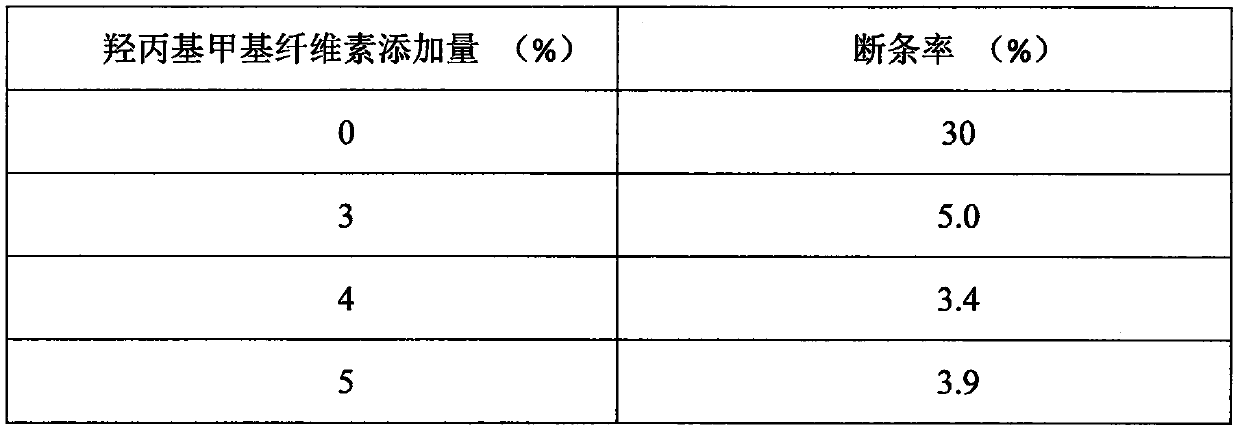

[0028] See figure 1 with figure 2 , The present invention provides a technical solution:

[0029] In this embodiment, the addition amount of methyl cellulose accounts for 3% of the starch weight.

[0030] Take 100 kg of cleaned rice, soak it for 1 hour, grind it into a rice slurry with a refiner, pass it through an 80-mesh sieve, and then partially dewater the rice slurry. Add 3 kg of methyl cellulose to the dehydrated rice noodles, mix them thoroughly, and adjust the moisture content of the mixture to 35%. 0.1MPa steam is passed into the mixture for initial steaming for 6 minutes, so that the gelatinization degree of the rice flour reaches 70%. The gelatinized mixture is extruded into a sheet with an extruder, and then extruded into a strip, and then steamed with 0.1MPa steam. The steaming time is 2min. The obtained rice noodles are showered with cold water at 0℃. Wash for 2 minutes, and finally sterilize the rice noodles with low vacuum packaging. The sterilization temperatu...

Embodiment 2

[0032] See figure 1 with figure 2 , The present invention provides a technical solution:

[0033] In this embodiment, the addition of methyl cellulose accounts for 4% of the weight of starch.

[0034] Take 100 kg of cleaned rice, soak it for 2 hours, grind it into rice slurry with a refiner, pass through a 100-mesh sieve, and then partially dewater the rice slurry. Add 4 kg of methyl cellulose to the dehydrated rice noodles, mix them thoroughly, and adjust the moisture content of the mixture to 40%. Pass 0.2MPa steam into the mixture for initial steaming for 7 minutes to make the gelatinization degree of the rice flour reach 75%. The gelatinized mixture is extruded into a sheet with an extruder, and then extruded into a strip, and steamed with 0.2MPa steam. The steaming time is 2.5min, and the rice noodles obtained are cold water at 5℃. Rinse for 2 minutes, and finally sterilize the rice noodles with low vacuum packaging. The sterilization temperature is 95℃, and the time is 4...

Embodiment 3

[0036] See figure 1 with figure 2 , The present invention provides a technical solution:

[0037] In this embodiment, the addition of methyl cellulose accounts for 5% of the weight of starch.

[0038] Take 100kg of cleaned rice, soak it for 2h, grind it into rice slurry with a refiner, pass through an 80-mesh sieve, and then partially dewater the rice slurry. Add 5 kg of methyl cellulose to the dehydrated rice noodles, mix them thoroughly, and adjust the moisture content of the mixture to 45%. Pass 0.2MPa steam into the mixture for initial steaming for 8 minutes to make the gelatinization degree of the rice flour reach 80%. The gelatinized mixture was first extruded into a sheet with an extruder, and then extruded into a strip, and steamed with 0.2MPa steam. The steaming time was 3min. The obtained rice noodles were showered with cold water at 10℃. Wash for 2 minutes, and finally sterilize the rice noodles with low vacuum packaging. The sterilization temperature is 95℃, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com