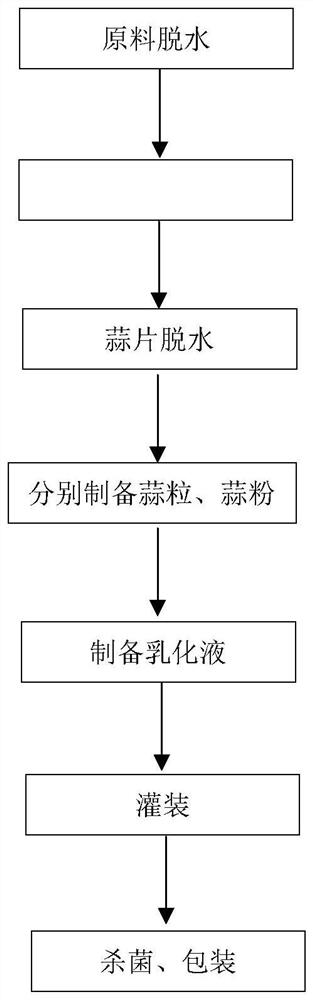

A preparation method of oil-water emulsification and rehydration canned garlic and a special garlic cutting device

A technology of oil-water emulsification and garlic granules, which is applied in the direction of food ingredients as emulsifiers, applications, and preservation of fruits and vegetables. It can solve the problems of affecting the nutritional content of products, not being easy to mass-produce and process, and affecting the taste of finished products, so as to achieve oil-water emulsification Homogenization effect, guaranteed storage period, and shortened action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Comparative example of preparation process of garlic clove slices

[0039] Treatment group:

[0040] (1) Raw material processing: Peel garlic cloves, select fresh, white color, no rot and no moldy garlic cloves, peel off the skin and remove the roots, and then wash with water and sodium sulfite solution (at room temperature);

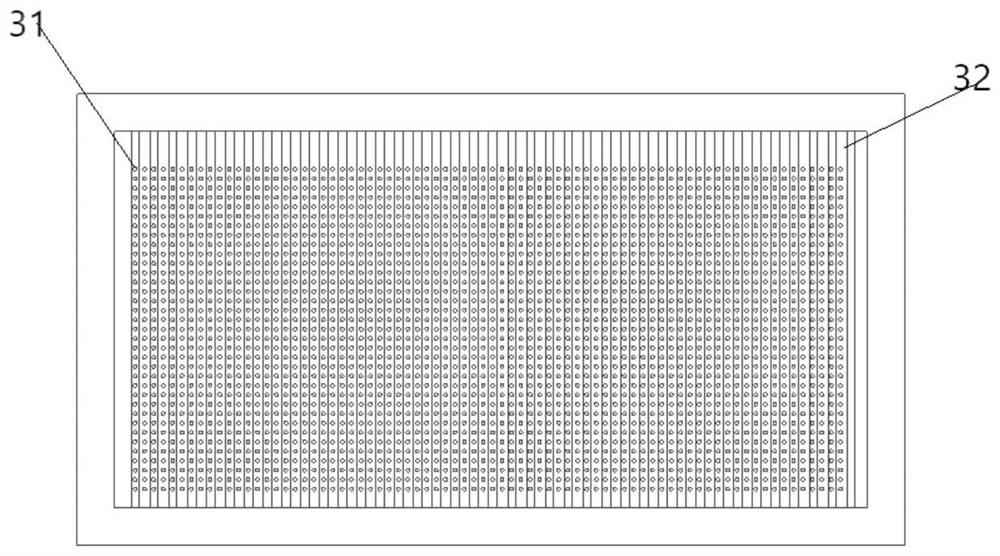

[0041] (2) Slicing: adopt the garlic cutting device of the present invention to cut the garlic cloves after step (1) into 3mm thick slices (carry out at room temperature);

[0042] (3) Preparation of dehydrated garlic slices: the garlic slices prepared in step (2) are dehydrated with hot air at a temperature of about 65° C. to obtain dehydrated garlic slices with a water content of 8%.

[0043] Three gradients of 1200mg / L, 1400mg / L, and 1500mg / L were respectively selected from the sodium sulfite solution used above as treatment group 1, treatment group 2, and treatment group 3 for the preparation of dehydrated garlic slices.

[0044] Comparison...

Embodiment 2

[0057] Dehydrated garlic slices preparation process comparison example

[0058] Sliced garlic:

[0059] (1) Raw material processing: Peel garlic cloves, select fresh, white color, no rot and no moldy garlic cloves, peel off the skin and remove the roots, and then wash with water and sodium sulfite solution (at room temperature);

[0060] (2) Slicing: using the garlic cutting device of the present invention to cut the garlic cloves treated in step (1) into thin slices with a thickness of 3 mm (at room temperature).

[0061] The sodium sulfite solution concentration that adopts in the above-mentioned steps is 1400mg / L.

[0062] Hot air, freeze drying combined dehydration treatment:

[0063] a. Take garlic slices and dry them in hot air at 45°C for 2.5 hours;

[0064] b. Spread the hot-air-dried garlic slices to cool to room temperature, and then freeze-dry them: put them in a freeze dryer, and when the temperature reaches -45°C, turn on the vacuum pump to an absolute pressu...

Embodiment 3

[0069] The preparation process of oil-water emulsification and rehydration garlic grain can of the present invention:

[0070] (1) Raw material processing: Peel garlic cloves, select fresh, white color, no rot and no moldy garlic cloves, peel off the skin and roots, and clean with water and 1200mg / L sodium sulfite solution in turn;

[0071] (2) slice: adopt garlic cutting device of the present invention to cut the garlic clove after step (1) into 5mm thick thin slices; Wherein the flowing sodium sulfite solution concentration on blade surface is 1200mg / L;

[0072] (3) Preparation of dehydrated garlic slices: the garlic slices prepared in step (2) are dehydrated: first place them in hot air at 45°C for 2.5 hours; Freeze drying: put it in a freeze dryer, when the temperature reaches -45°C, turn on the vacuum pump to an absolute pressure of 85Pa, set the maximum temperature of the heating plate to 50°C, and the minimum temperature to 30°C, until the water content of the garlic sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com