Online measuring method of metallurgical gas calorific valuebased on combustion system running parameters

A technology of operating parameters and combustion system, which is applied in the field of online measurement of the calorific value of metallurgical gas based on the operating parameters of the combustion system, can solve the problem of running without an online gas calorific value analyzer, interfering with the operation judgment of operators, affecting the optimal operation of combustion equipment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

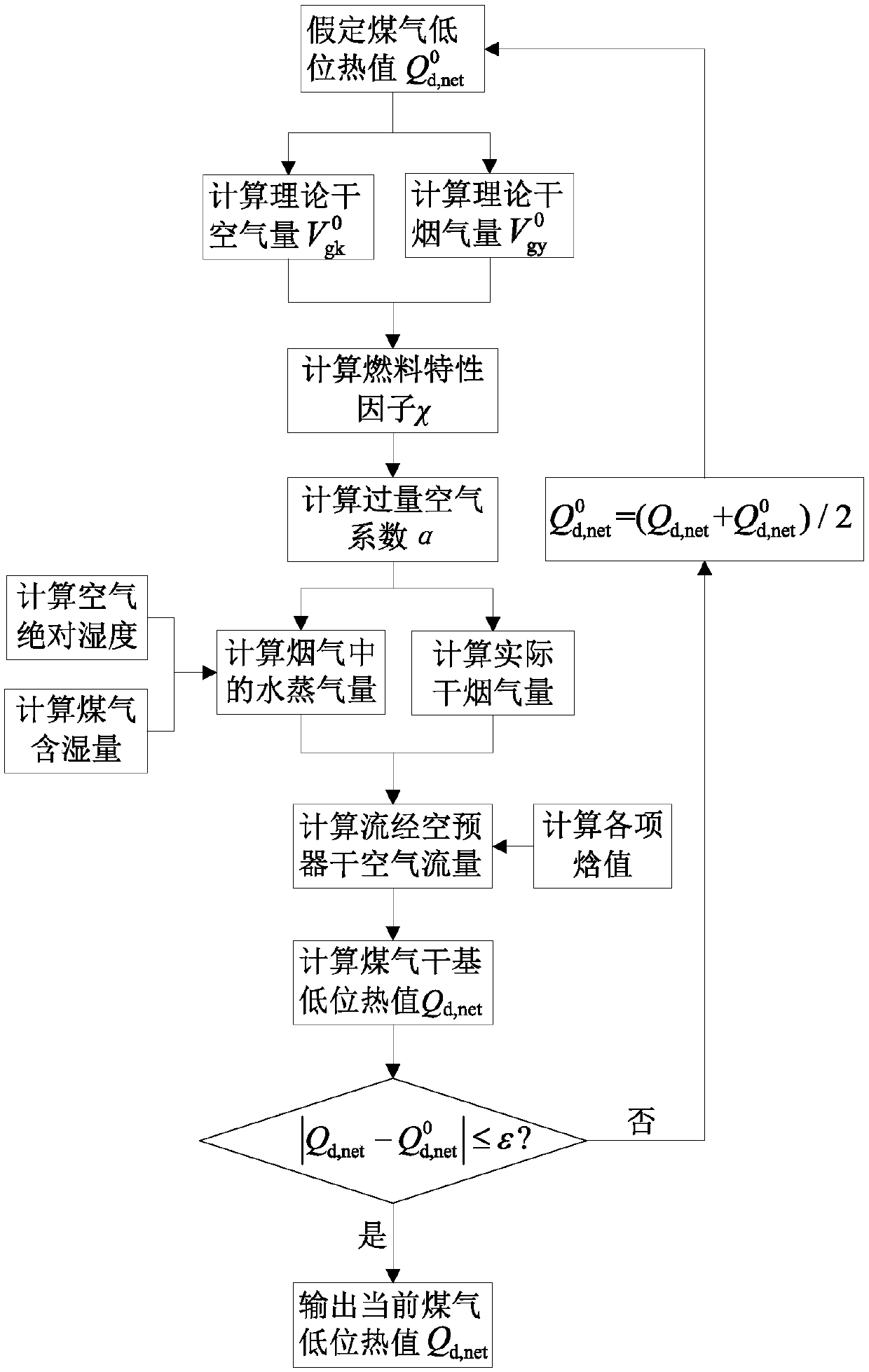

[0082] The present invention is described in further detail now in conjunction with accompanying drawing.

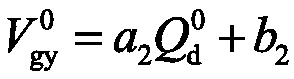

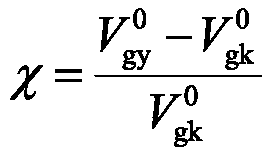

[0083] Such as figure 1 As shown, in this embodiment, the specific implementation steps of the online calculation method for the calorific value of metallurgical gas based on the operating parameters of the combustion system are as follows:

[0084] Step 1. Obtain real-time data on the operating parameters of the combustion system; the obtained operating parameters of the combustion system include but are not limited to: flue gas oxygen content, local atmospheric pressure, relative atmospheric humidity, ambient temperature, gas pressure, gas temperature, and air preheating The inlet temperature of the flue gas side of the air preheater, the outlet temperature of the flue gas side of the air preheater, the inlet temperature of the air side of the air preheater and the outlet temperature of the air side of the air preheater;

[0085] The measuring point of the flue gas ox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com