Visual measurement experiment device of critical heat flux density of integrally sintered rectangular narrow slit channel

A critical heat flux and experimental device technology, which is applied in the field of experimental devices for visual measurement of critical heat flux in rectangular narrow slit channels, can solve the problems that no experimental devices have been found, achieve simple structure, ensure safety, and solve axial expansion and extrusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

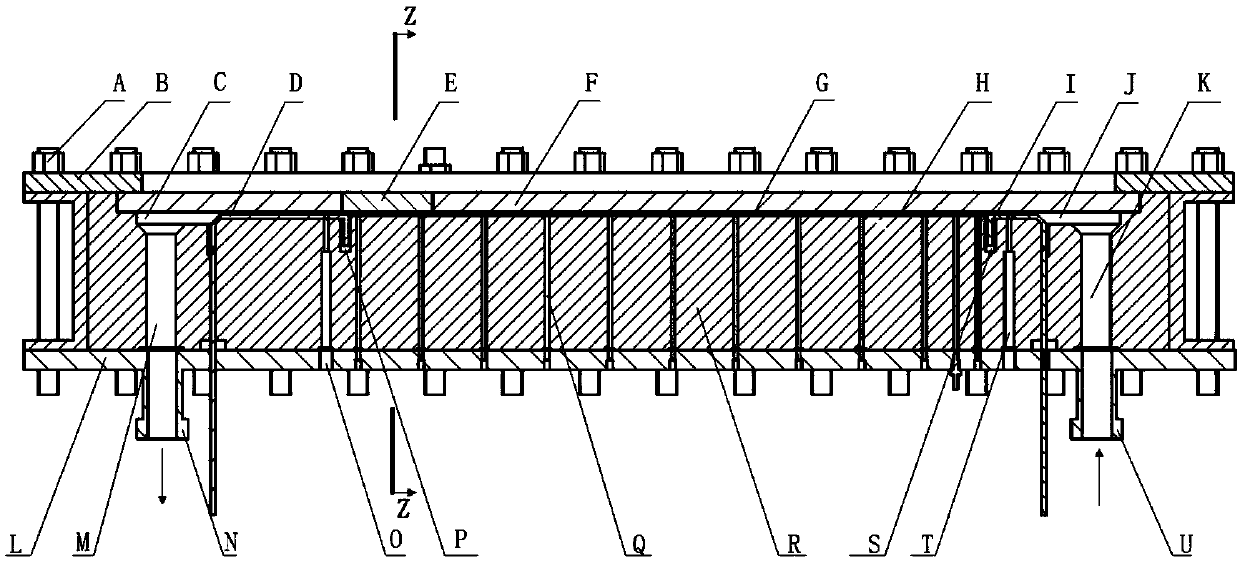

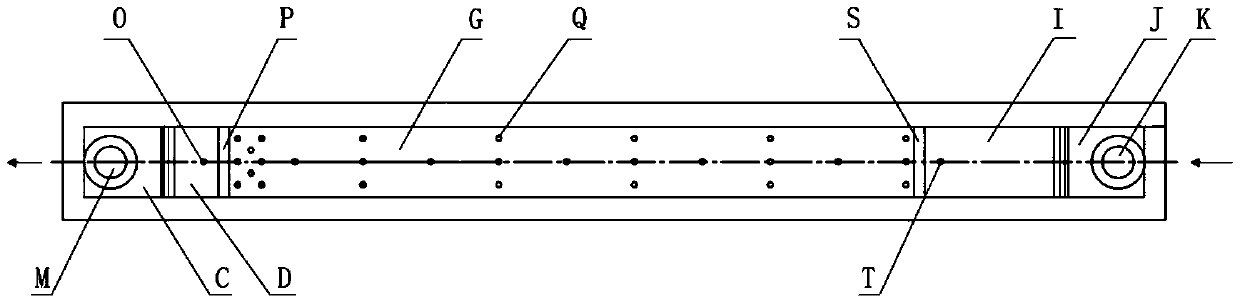

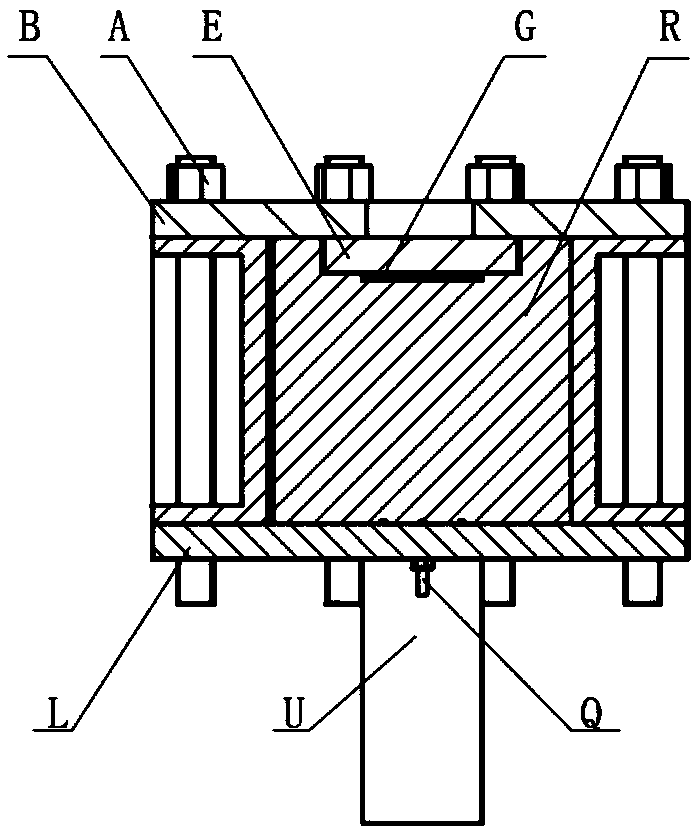

[0037] Such as figure 1 , figure 2 and image 3 As shown, the present invention is an integrally sintered rectangular narrow slit channel critical heat flux visual measurement experimental device, which includes an integrally sintered ceramic substrate R, a heating plate G inserted into the concave channel on one side of the integrally sintered ceramic substrate R, and pressed on There is a gap between the concave channel and the heating plate G, the stainless steel plate F embedded with quartz glass E, the width of the heating plate G and the width of the concave channel are fastened by tolerance fit, and the length of the heating plate G is shorter than that of the concave channel length, with cavities left on both sides; it also includes a conductive circuit composed of conductive devices embedded in the integral sintered ceramic substrate R, that is, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com