Overflow type hydraulic balance valve with vibration damping function

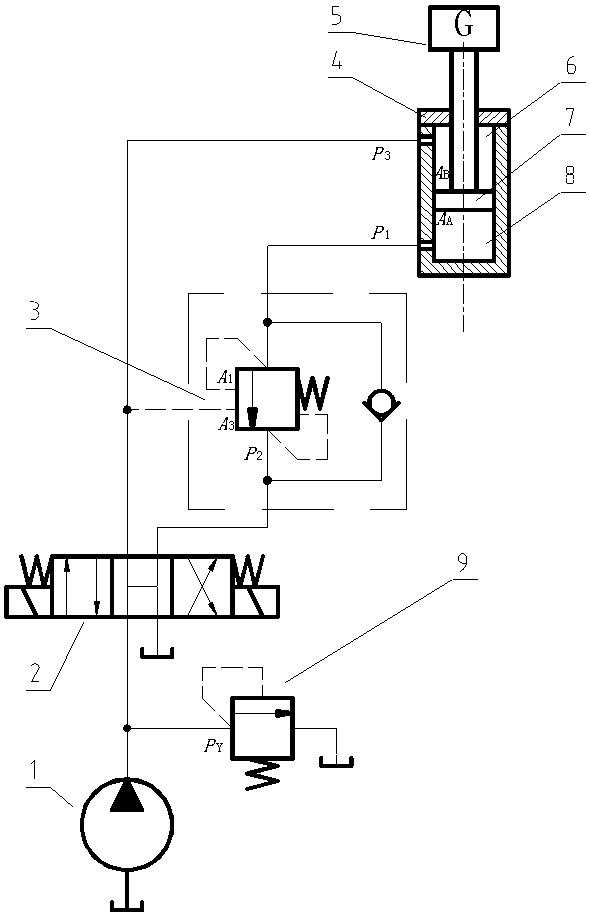

A hydraulically balanced, overflow-type technology, used in fluid pressure actuation devices, servo motors, servo motor components, etc., to solve problems such as the rapid and slow descending of the hydraulic cylinder piston, the vibration of the hydraulic system, and the increase of noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

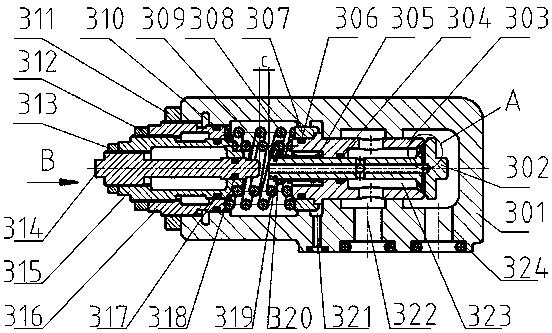

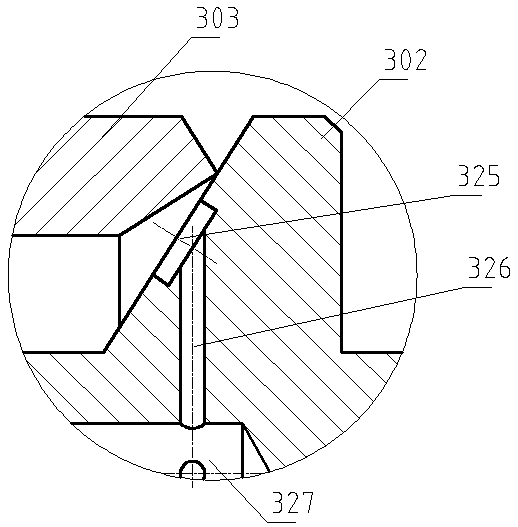

[0063] As shown in the figure, the specific implementation method is as follows:

[0064] A relief type hydraulic balance valve with a vibration damping function, comprising a valve body 301, the valve body 301 is provided with an oil inlet chamber 324, an oil outlet chamber 322 and a control oil chamber 321, and a main valve is slid through the valve body 301 Spool 303, the contact surface between the valve body 301 and the main spool 303 adopts clearance fit, the center of the main spool 303 slides through a check spool 302, and the main spool 303 and the check spool 302 run through the oil inlet chamber 324, the oil outlet chamber 322 and the control oil chamber 321, the control oil chamber 321 is not connected with the oil inlet chamber 324 and the oil outlet chamber 322, and the end of the one-way valve core 302 away from the oil inlet chamber 324 is sleeved with a one-way valve core Spring 305, one end of the one-way spool spring 305 presses against the end face of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com