Hot blast type wind power generating set blade deicing device

A technology of wind power generating set and hot air blast, which is applied in the direction of wind power engine, wind power engine monitoring, wind power generation, etc. It can solve the problems of power drop, broken unit, shutdown, etc., and achieve the effect of high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

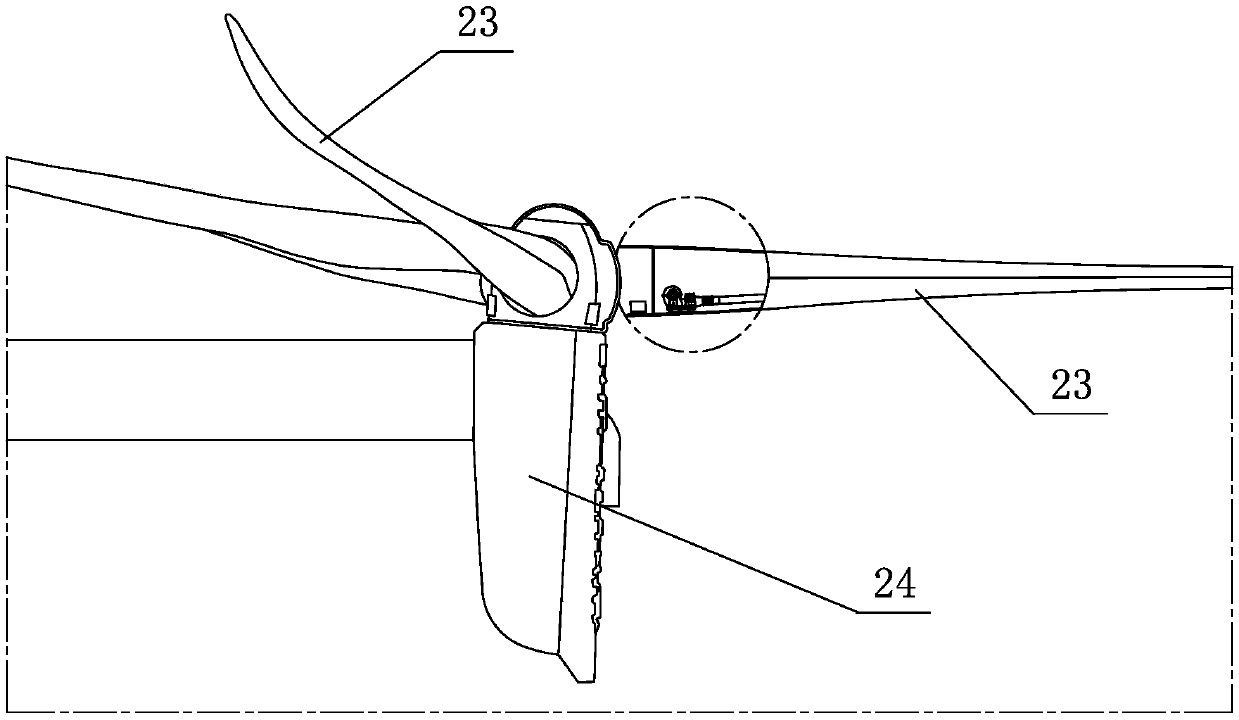

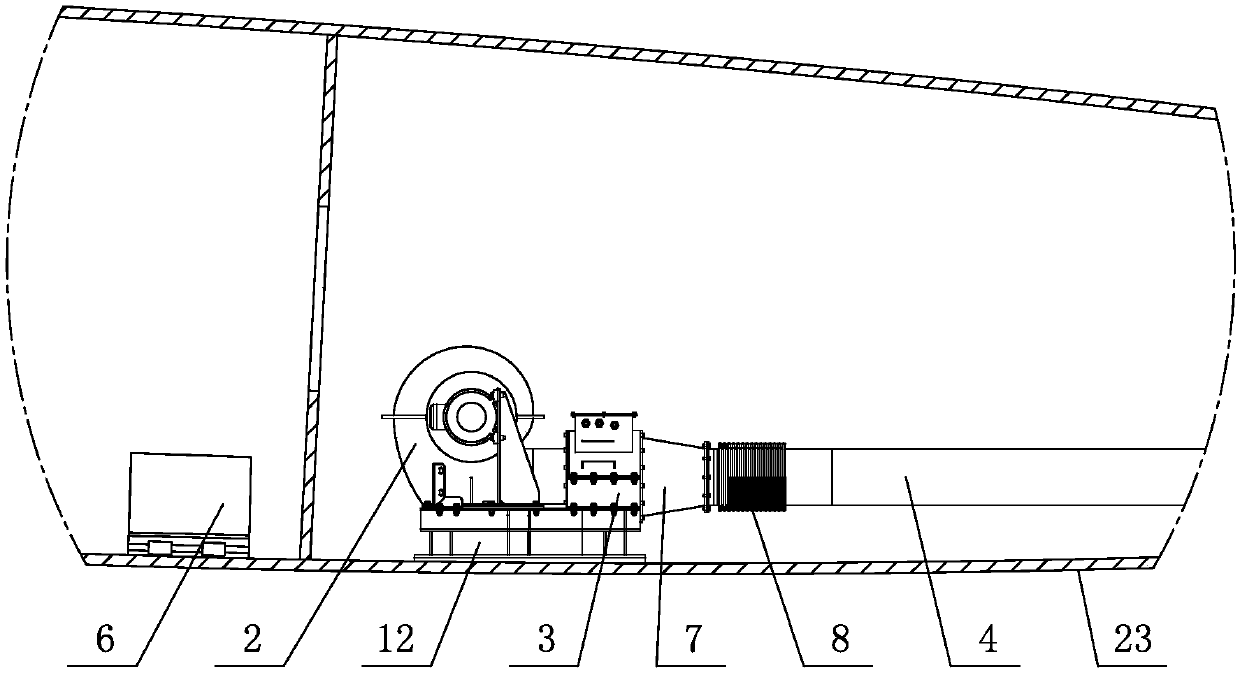

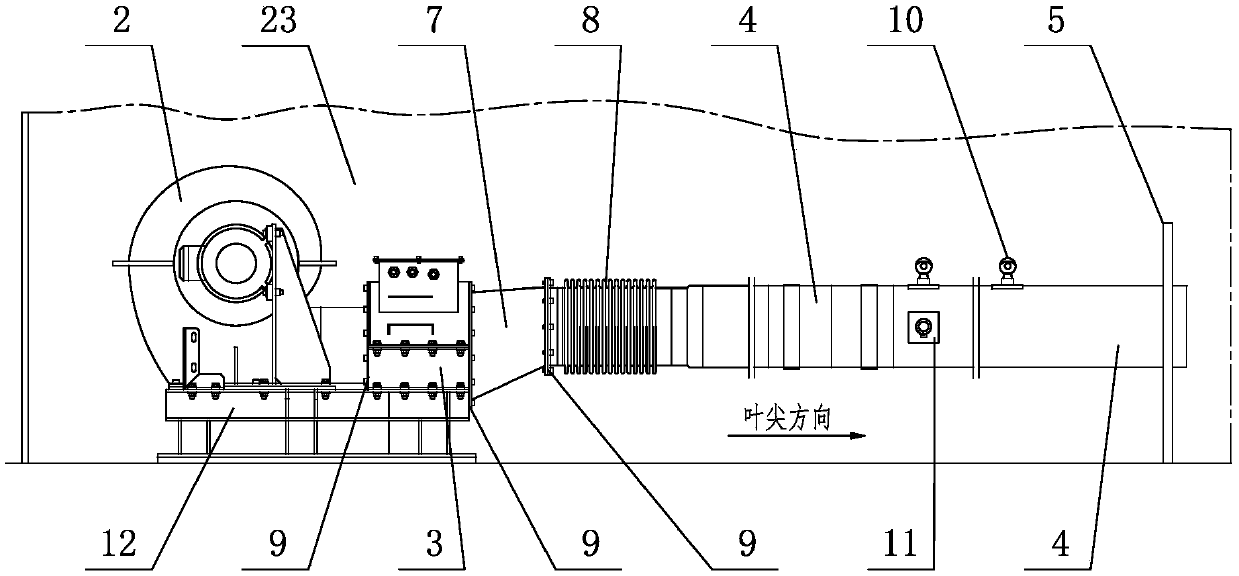

[0024] exist figure 1 figure 2 In the shown embodiment 1, a deicing device for blades 23 of a hot blast type wind power generating set 24 includes a heating device and a ventilation duct arranged in the inner cavity of the blade, and the heating device and ventilation duct are arranged in the Inside the blade leading edge cavity 1 (see Figure 4 , the oblique dotted line in the figure is the center line of the blade web), the heating device includes a blower 2 and a heater 3 connected to the outlet end of the blower, the output end of the heater is connected to the air pipe 4, and the air outlet of the air pipe The end wears on the windshield 5 provided in the inner cavity of the blade (see image 3 ), the edge shape of the windshield matches the cross-sectional shape of the blade at the installation position, the distance between the windshield and the root of the blade is greater than one tenth of the total length of the blade, and the air outlet of the air duct The end ...

Embodiment 2

[0030] exist Figure 5 In the shown embodiment 2, a telescopic tube 13 is sleeved inside the air duct, and the outer diameter of the telescopic tube is compatible with the inner diameter of the air duct. The outlet end of the telescopic tube is provided with a sliding support plate 14, and a pulley is fixed on the sliding support plate. Rope 15, a stay rope motor 16 and a stay rope drive wheel 17 are arranged on the windshield, and a reversing pulley 18 is arranged on the blade inner wall away from the windshield, and the stay rope is wound around the stay rope drive wheel and the pulley , the inner wall of the paddle is also provided with a telescopic limit switch; the rope motor and the telescopic limit switch are both connected to the control cabinet. A telescopic tube is set in the air duct, and the length of the telescopic tube protruding from the air duct is adjusted by driving the cord motor, and the telescopic tube is pulled out or retracted from the air duct by the fo...

Embodiment 3

[0032] exist Figure 6 In the shown embodiment 3, the outlet end of the telescopic tube is connected with a guide tube 19, and the guide tube is an elastic corrugated tube, and the outer circumference of the guide tube is fixed with a guide plate 20 (see Figure 7 ), on the guide plate there are four adjusting screws 21 symmetrically centered on the axis of the telescopic tube, one end of the adjusting screw is screwed to the guide plate through a nut hinged with the guide plate, and the other end of the adjusting screw is hinged to a sliding support plate The adjusting motor 22 is connected, and the adjusting motor is connected to the control cabinet. A guide tube is set at the air outlet end of the telescopic tube, and the outlet of the guide tube is deflected in a specific direction (for example, deflected to the windward side of the blade) by controlling and adjusting the number of rotations and the direction of rotation of the motor, so that the hot air can be aligned wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com