Sea-crossing water suspended high-speed rail tunnel structure, construction method thereof, and control method

A technology of tunnel structure and water suspension, which is applied to underwater structures, infrastructure engineering, pontoon bridges, etc. It can solve the problems of unfeasible construction, achieve the effect of ensuring horizontal position and stability, and improving the ability of anti-rotation and anti-fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

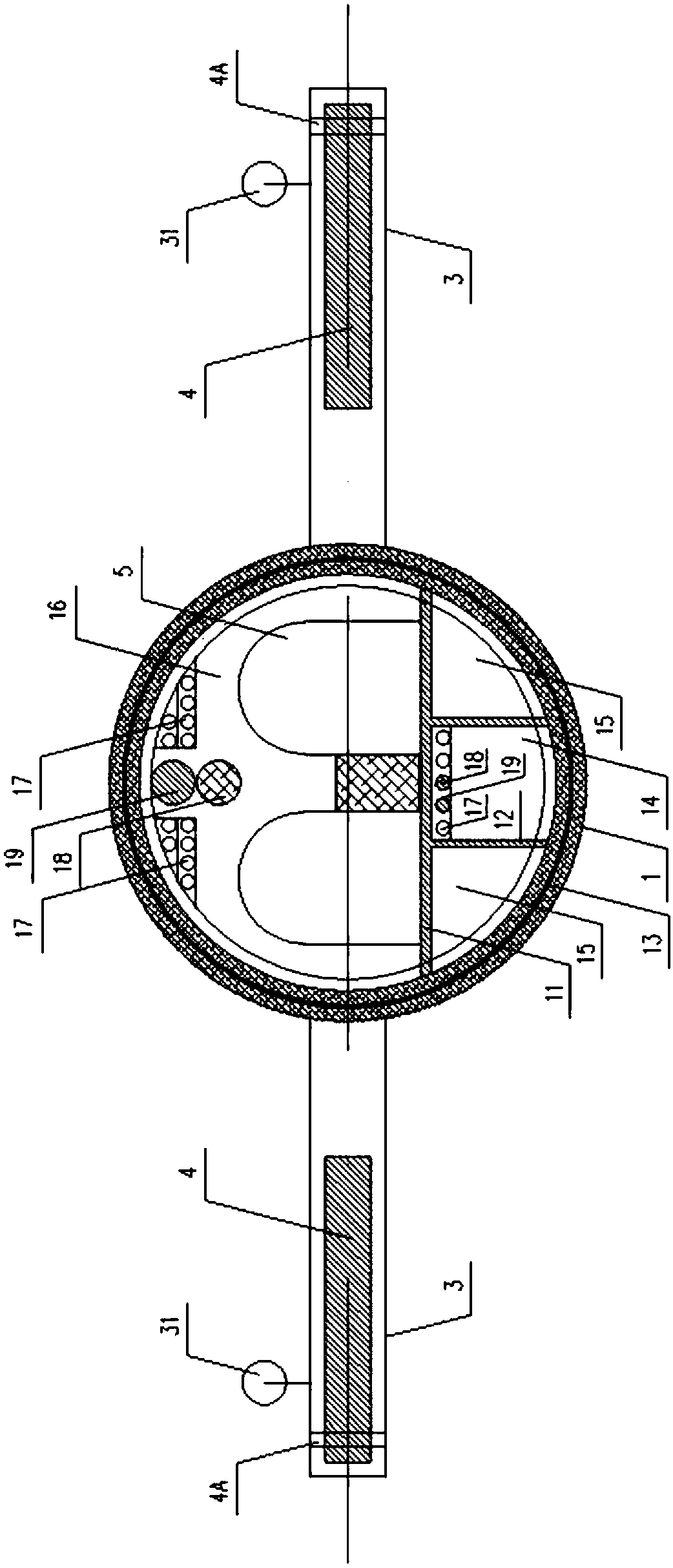

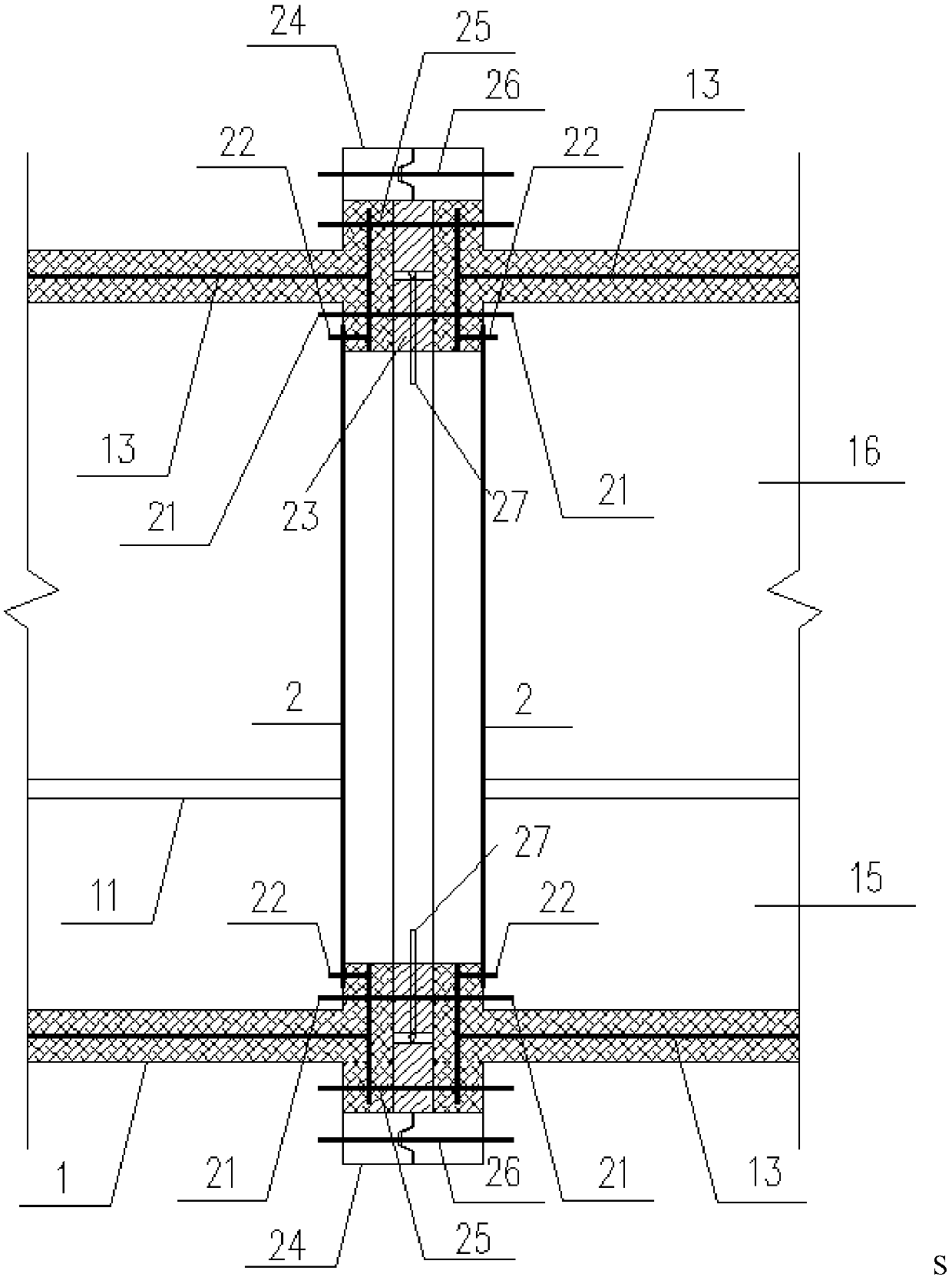

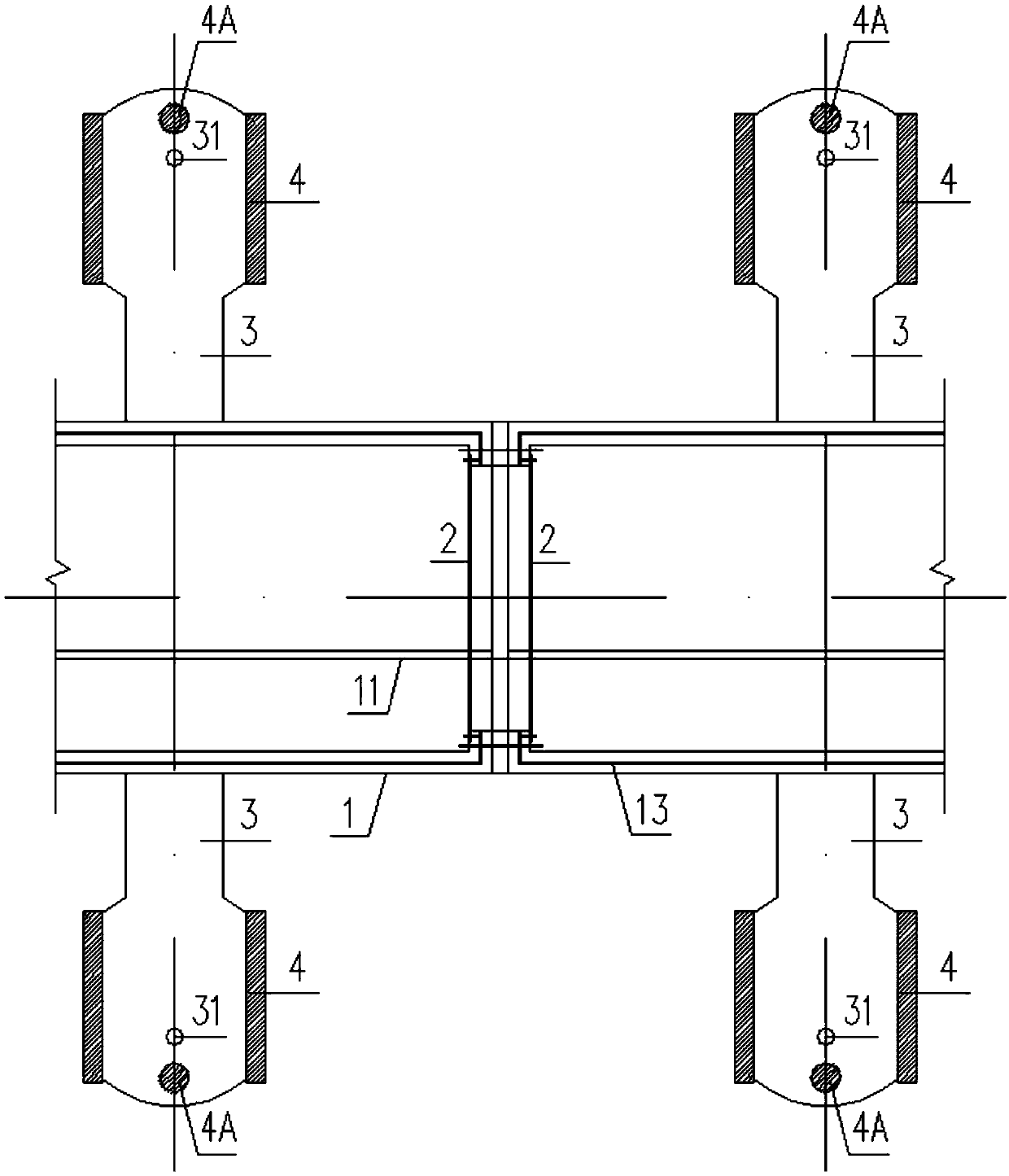

[0066] Such as Figure 1-9 As shown, a high-speed rail tunnel structure suspended in seawater includes a pipe body that can be suspended in water. The pipe body is formed by fixed connection of multiple pipe sections 1, and each pipe section 1 is fixed with a pipe section to separate the pipe sections to form an upper cabin. 16 and the reinforced concrete horizontal partition 11 of the lower compartment, the upper compartment has two high-speed rail airtight tunnels 5 arranged along the length of the pipe body, and the high-speed iron airtight tunnel 5 is provided with a high-speed rail track bed 53, and the pipe joint 1 Reinforced concrete fins 3 are arranged symmetrically in the outer horizontal direction.

[0067] In this embodiment, the two high-speed rail airtight tunnels 5 are surrounded by steel airtight tunnel shells 51 fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com