Water-permeable asphalt pavement structure capable of suppressing road surface reflection cracks

A technology for asphalt pavement and reflective cracks, which is applied to roads, roads, pavement details, etc., can solve problems such as reflective cracks that are prone to occur, and achieve the effects of inhibiting the generation and extension of reflective cracks, good adhesion, and improved shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

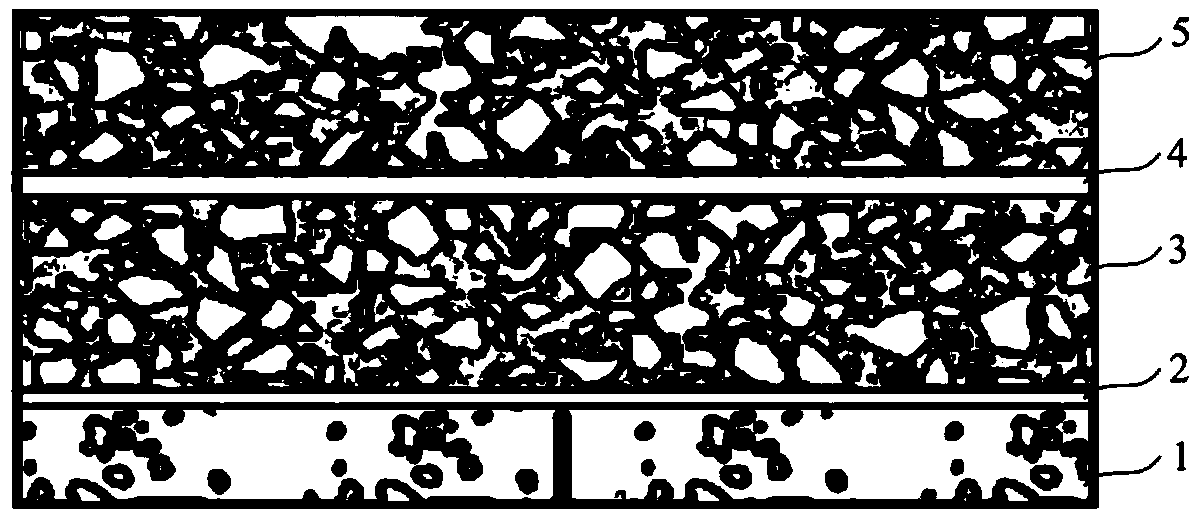

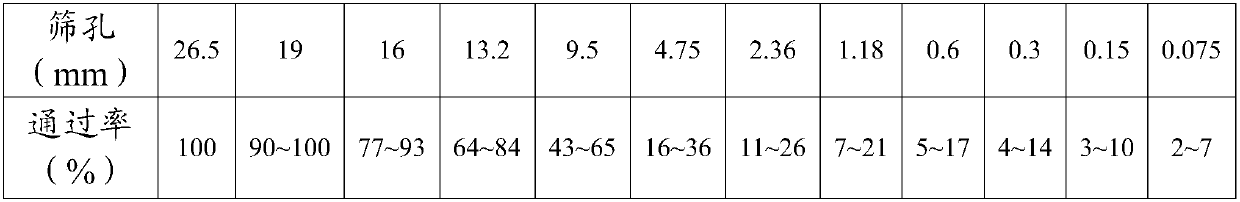

[0048] When the nominal maximum particle size of the special graded modified asphalt mixture layer is 19mm, or 13.2mm, the thickness of the high-viscosity asphalt mixture is 30mm-50mm, the void ratio is 8%-12%, and it is stabilized by aggregates, fillers, and fibers. The high-viscosity modified asphalt binder is composed of No. 70 asphalt and modifier, and the modifier accounts for 10% to 13% of the total mass of the high-viscosity modified asphalt binder; aggregate It is composed of coarse aggregate and fine aggregate. The coarse aggregate is made of diabase, basalt or limestone, the fine aggregate is made of limestone; the filler is made of limestone slag; It is 0.1%-0.6% of the mass of the mixture. The sealing layer 4 adopts SBS modified emulsified asphalt slurry sealing layer, the thickness is 0.5mm~1.0mm.

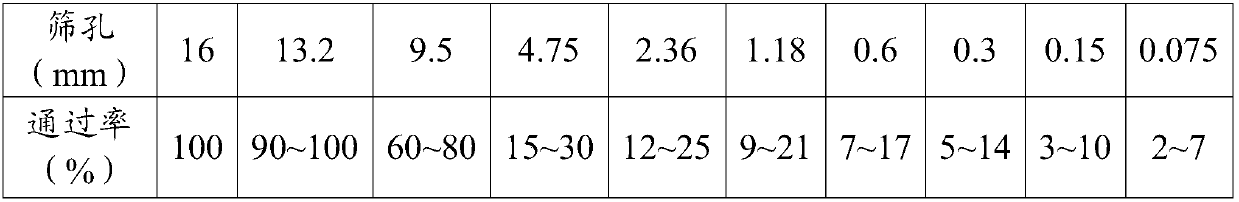

[0049] The permeable asphalt mixture layer adopts OGFC-13 type open graded asphalt mixture layer, the thickness is 40mm~50mm, and the void ratio is 18%~22%. The mass o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com