Ultrahigh-strength magnesium alloy preparation method adopting prestretching composite two-stage ageing technology

A composite two-stage, magnesium alloy technology, applied in the field of magnesium alloy processing, can solve the problems of inability to prepare large components and structural diversification, limited processing size, low production efficiency, etc., to shorten the aging treatment time and improve the yield strength. , reducing the effect of grain boundary precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

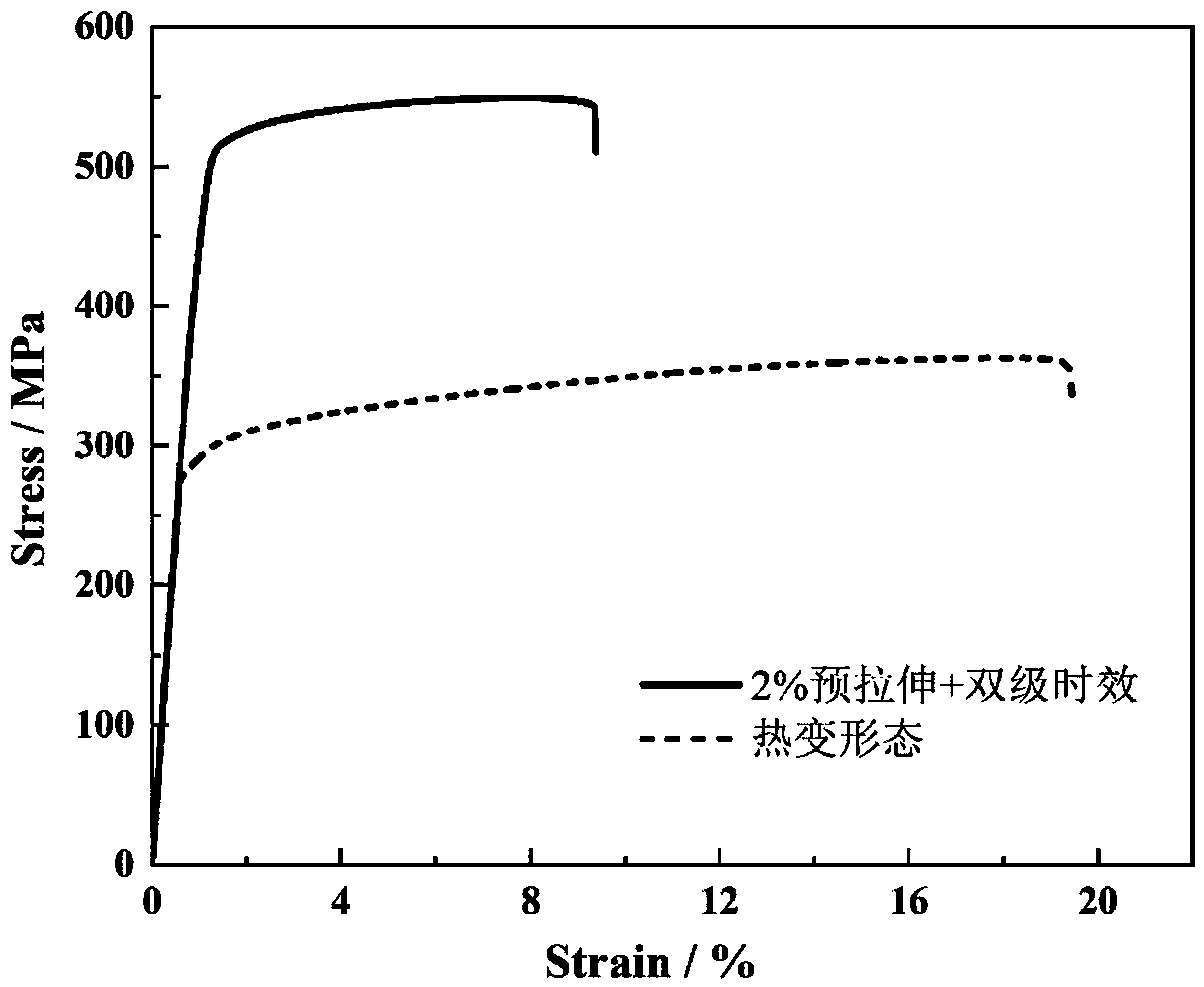

[0020] The hot-extruded Mg-10Gd-1Er-1Zn-0.6Zr (wt.%) magnesium alloy was pre-stretched at room temperature, pre-stretched parallel to the extrusion direction to produce 2% deformation, and then double-stage aging: first Heat preservation at 100°C for 1 hour for first-stage aging, water quenching and cooling, then aging at 200°C for 36 hours, water quenching and cooling to room temperature. Carry out tensile test on the alloy after the above treatment until it breaks, and obtain the stress-strain curve, such as figure 1 As shown, the yield strength is 454MPa, the tensile strength is 483MPa, and the elongation is 11.1%.

Embodiment 2

[0022] The hot-extruded Mg-10Gd-1Er-1Zn-0.6Zr (wt.%) magnesium alloy was pre-stretched at room temperature, pre-stretched parallel to the extrusion direction to produce 5% deformation, and then double-stage aging: first Heat preservation at 100°C for 1 hour for first-stage aging, water quenching and cooling, then aging at 200°C for 34 hours, water quenching and cooling to room temperature. The alloy after the above treatment is subjected to a tensile test until it breaks, and a stress-strain curve is obtained. The yield strength is 469MPa, the tensile strength is 488MPa, and the elongation is 9.8%.

Embodiment 3

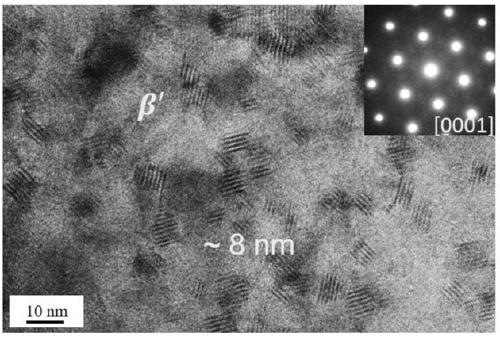

[0024] The hot-extruded Mg-12Gd-1Er-1Zn-0.6Zr (wt.%) magnesium alloy was pre-stretched at room temperature, pre-stretched parallel to the extrusion direction to produce 2% deformation, and then double-stage aging: first Heat preservation at 100°C for 1 hour for first-stage aging, water quenching and cooling, then aging at 200°C for 40 hours, water quenching and cooling to room temperature. Carry out tensile test on the alloy after the above treatment until it breaks, and obtain the stress-strain curve, such as figure 2 As shown, the yield strength is 506MPa, the tensile strength is 549MPa, and the elongation is 8.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com