A kind of preparation method of polyurethane solid tire for mining vehicle

A solid tire and polyurethane technology, applied in the field of polyurethane materials, can solve the problems of good compression resilience of tires, small load deformation, and heavy load of mining vehicles, so as to improve tear strength and wear resistance, and reduce load shape. Effect of variable, good hydrolysis resistance and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

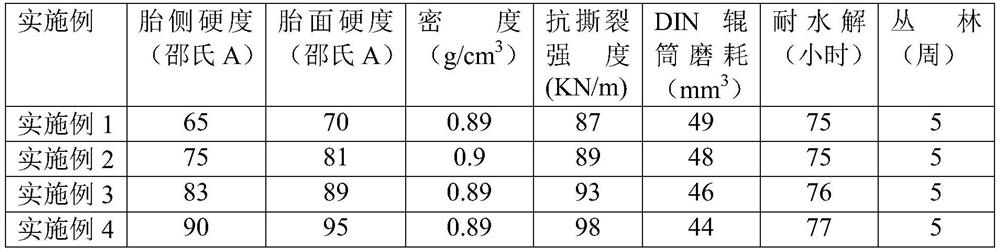

Examples

preparation example Construction

[0010] The steps of the preparation method of this polyurethane solid tire for mining vehicles are as follows:

[0011] (1) Preparation of polyester polyol: mixing dibasic acid and polyol with a mass ratio of 100: (65~80), carrying out polyesterification reaction under the action of catalyst A to obtain polyester polyol, Wherein the dibasic acid is a mixture of sebacic acid and adipic acid in a mass ratio of 100:(0-100), and the polyhydric alcohol is 1,6-hexanediol, neopentyl glycol and trimethylolpropane A mixture with a mass ratio of 100:(10~50):(0~0.5);

[0012] (2) Preparation of component A: mix the polyester polyol prepared in step (1) with the chain extender and p-phenylene diisocyanate in a mass ratio of 100:(12~20):(8~14), Carry out the prepolymerization reaction, make the oligomer a with hydroxyl terminated, then oligomer a and hydroxyl terminated liquid rubber, organosilicon foam stabilizer, catalyst B, foaming agent with mass ratio 100: (20~50): (0.4~1):(1.8~3.5)...

Embodiment 1

[0029] (1) Mix 113kg of sebacic acid, 67.8kg of 1,6-hexanediol, 7.1kg of neopentyl glycol, 0.33kg of trimethylolpropane, and 0.8kg of tetraisopropyl titanate, and heat to 230°C under nitrogen protection Carry out the polyesterification reaction, and stop the reaction when the acid value is 0.8 mgKOH / g and the hydroxyl value is 112 mgKOH / g, and polyester polyol is obtained.

[0030] (2) Preparation of component A: Put 150kg of the polyester polyol prepared in step (1) into the reactor, heat it to 95°C, add 14.4kg of 3,3'-dichloro-4,4'-diaminodiphenyl Methyl methane, 3.6kg ethylene glycol, mix evenly, after the chain extender is completely dissolved, add 12kg p-phenylene diisocyanate, mix well, after the p-phenylene diisocyanate is completely dissolved, cool down with water bath, quickly drop to 70°C, react For one hour, add 85kg of hydroxyl-terminated polybutadiene acrylonitrile, 0.68kg of DC-3042, 3.1kg of catalyst triethylenediamine, and 0.34kg of water, and mix well to obtai...

Embodiment 2

[0034] (1) Mix 79.7kg of sebacic acid, 33.3kg of adipic acid, 63.3kg of 1,6-hexanediol, 15.8kg of neopentyl glycol, 0.19kg of trimethylolpropane, and 0.8kg of tetraisopropyl titanate, Under the protection of nitrogen, heat to 233°C for polyesterification reaction, stop the reaction when the acid value is 0.8 mgKOH / g, and the hydroxyl value is 86 mgKOH / g, to obtain polyester polyol.

[0035] (2) Preparation of component A: Put 150kg of the polyester polyol prepared in step (1) into the reactor, heat it to 95°C, add 16.2kg of 3,3'-dichloro-4,4'-diaminodiphenyl Methyl methane, 4.8kg ethylene glycol, mix evenly, after the chain extender is completely dissolved, add 15kg p-phenylene diisocyanate, mix well, after the p-phenylene diisocyanate is completely dissolved, cool down with water bath, quickly drop to 70°C, react For one hour, add 75.6kg of hydroxyl-terminated hydrogenated polybutadiene, 0.9kg of DC-3042, 4.2kg of catalyst triethylenediamine, and 0.34kg of water, and mix well...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com