Turning over method of cutter head of super large diameter shield machine

A technology of super-large diameter, shield machine, applied in the direction of transportation and packaging, load hanging components, etc., can solve problems such as difficulty in turning over, and achieve the effect of reducing workload, reducing construction costs, and speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

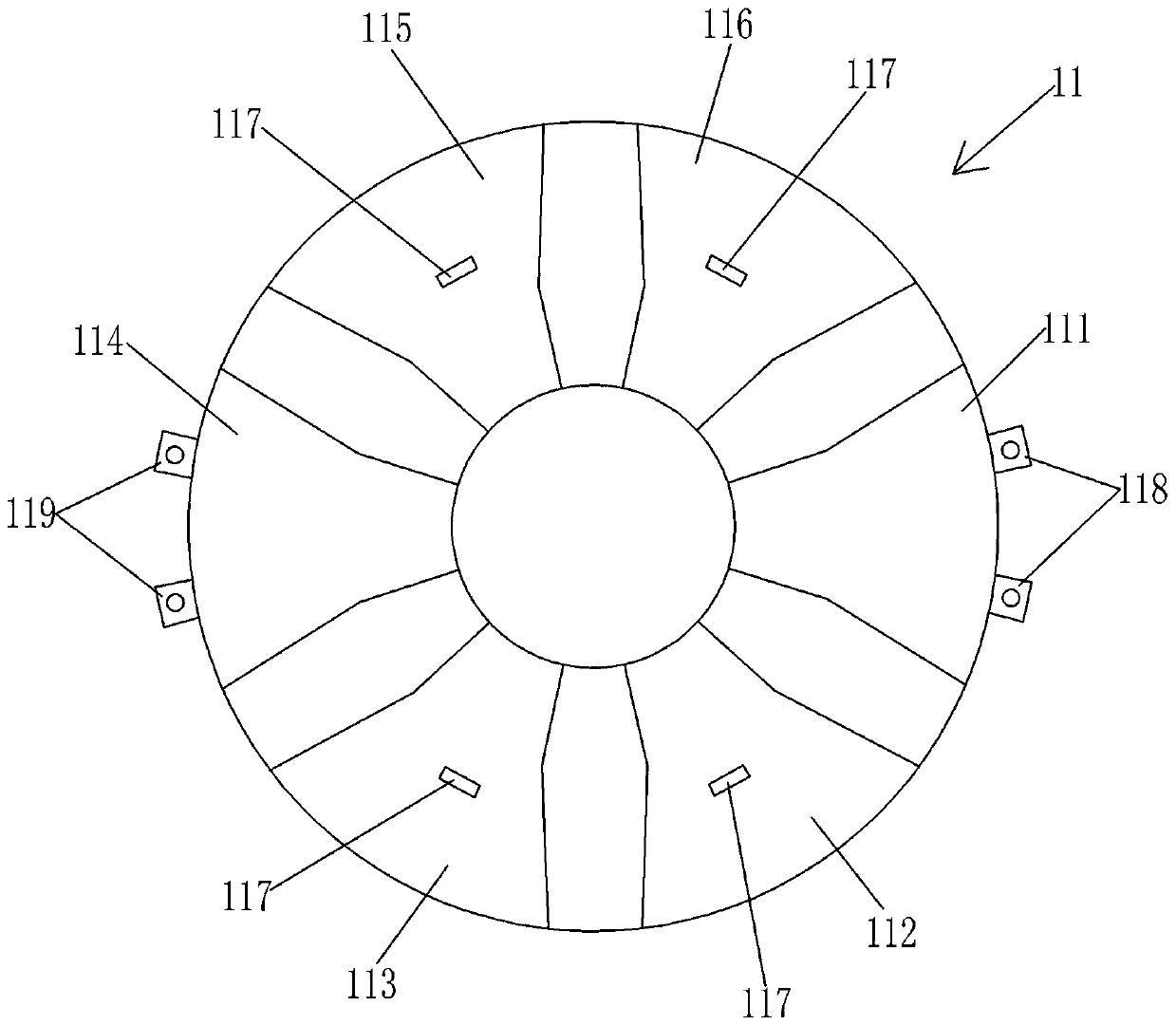

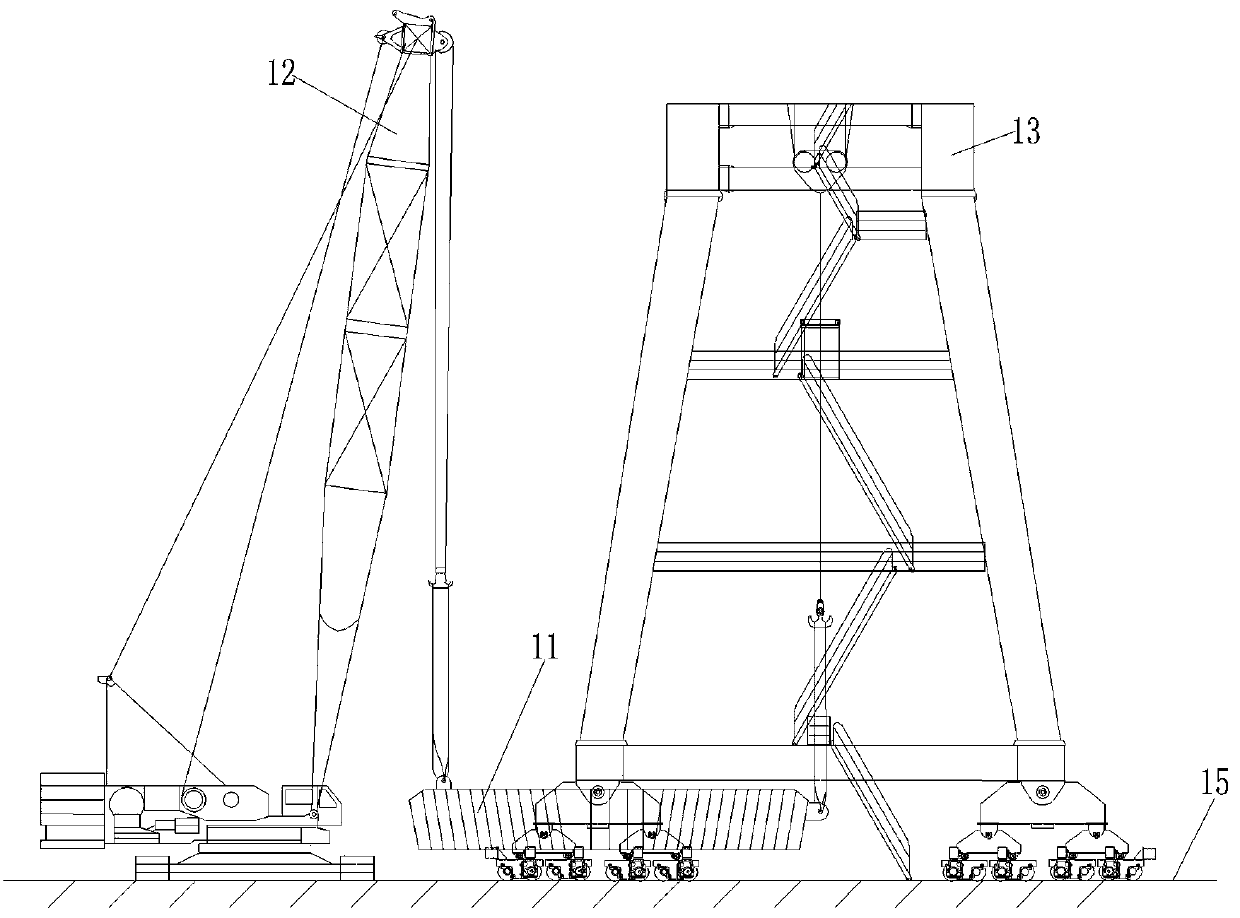

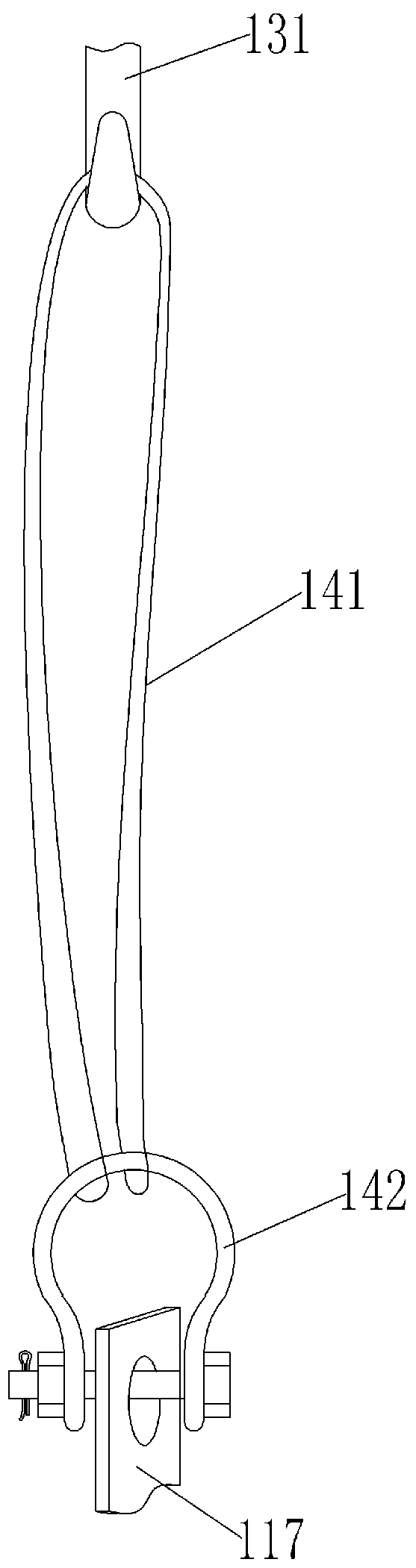

[0042] Please also refer to Figure 1 to Figure 6 .

[0043] The method for turning over the cutter head of the ultra-large diameter shield machine provided by the embodiment of the present invention is used for figure 1 The shown shield machine cutter head 11 is turning over. The shield machine cutter head 11 weighs more than 500 tons and consists of 1 central block, 6 main blocks, and 6 auxiliary blocks. It is the single block in the shield machine assembly process. The second lifter has the largest diameter and the heaviest weight. Due to the large size and weight of the cutterhead 11, the cutterhead 11 is inconvenient to transport as a whole. Therefore, one central block, six main blocks, and six auxiliary blocks of the cutterhead 11 are directly placed in the foundation pit for assembling the shield machine. Tailor welding is completed at the nearby welding assembly site, and then transferred to the vicinity of the foundation pit to avoid long-distance transportation. ...

Embodiment 2

[0064] see Figure 7 to Figure 9 .

[0065] The method for turning over the cutter head of the super-large-diameter shield machine provided by the embodiment of the present invention is used in the construction occasion of double tunnels side by side. For the corresponding working track of the gantry crane, a traversing track is laid between the two sets of working tracks, so that the gantry crane can walk from one set of working tracks to the other set of working tracks through the traversing track, so as to be used for the installation in the two tunnels. The cutter head of the shield machine is hoisted and turned over separately.

[0066] Specifically, such as Figure 7 As shown, the left working track 161 is laid on the construction site where the tunnel on the left is located, and the left operating track 161 passes through the left welding assembly site 162 for assembling the cutter head and the assembly site 162 for assembling shields on the construction site where th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com