a wheel reducer

A wheel-side reducer and reducer technology, applied in control devices, vehicle parts, transportation and packaging, etc., can solve the problems of high noise, low speed, time-consuming and labor-intensive disassembly and maintenance, etc., to achieve convenient installation, reduce costs, Effect of reducing machining workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

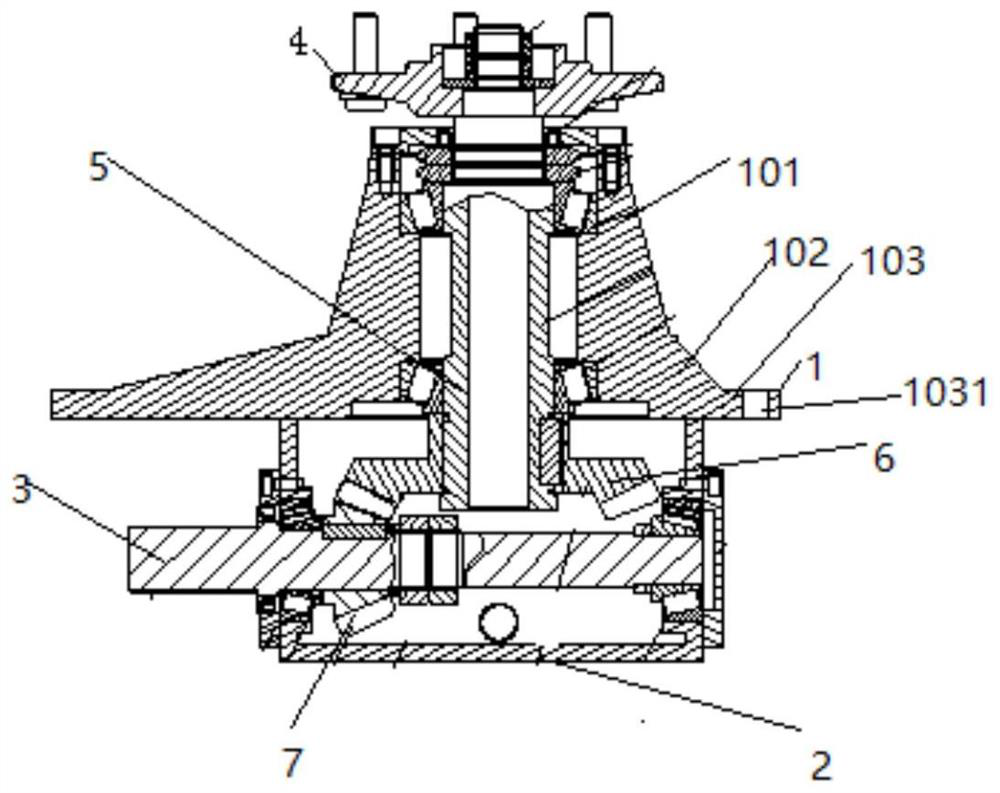

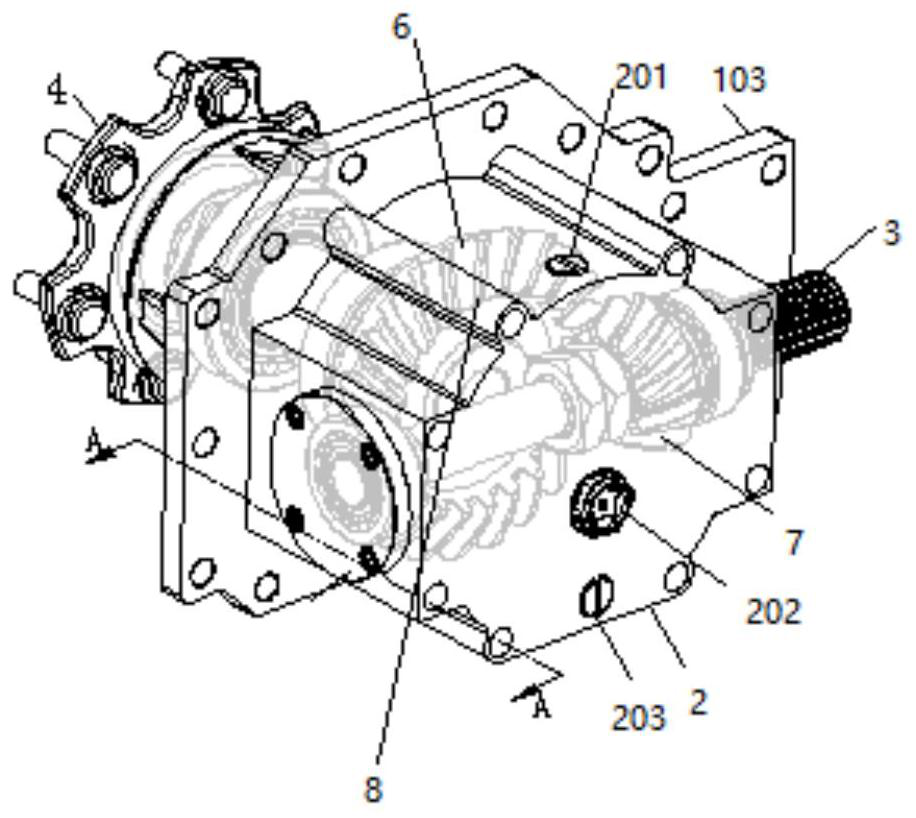

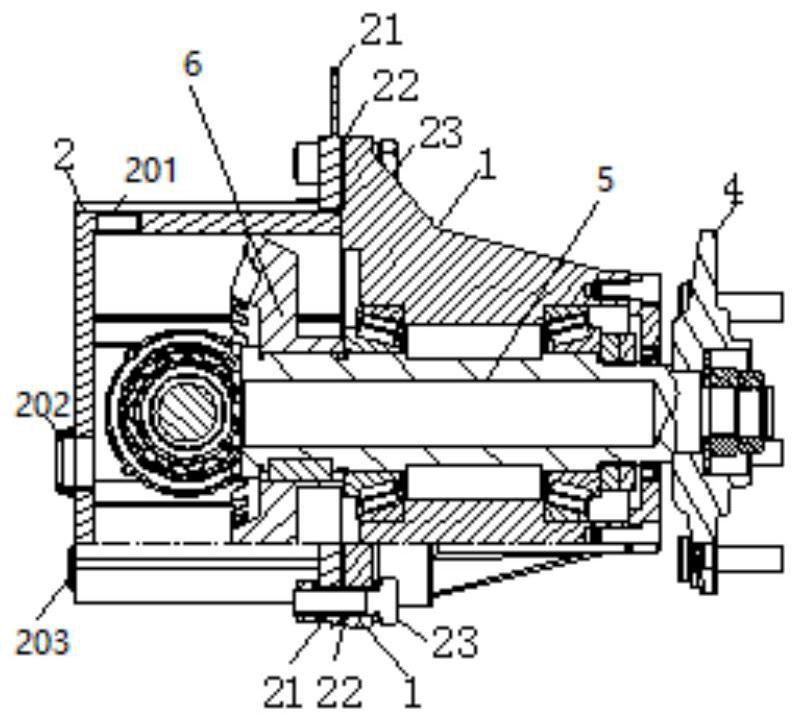

[0027] A wheel-side reducer, the wheel-side reducer includes a reducer housing, the reducer housing is provided with a transmission assembly for power transmission; the reducer housing includes an outer shell 1 and an inner shell 2, The outer shell 1 is connected to the inner shell 2; the present invention adopts a split design, which is beneficial to the forming of precision alloy casting molds, reduces the workload of machining, and is suitable for mass production and reduces costs; at the same time, it facilitates the installation of subsequent parts, At the same time, preferably, the transmission assembly in the present invention includes an input shaft system installed inside the inner housing 2 and an output shaft system installed inside the outer housing 1, and the input shaft system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com