Membrane preparation device and method for continuously preparing composite membrane with separation layer of PDMS

A technology of membrane devices and composite membranes, which is applied in semipermeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of long curing and drying time of coatings, damage to the health of operators, and high water content, so as to shorten the curing time Effects of drying time, increasing curing drying rate, and reducing crosslinking rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0061] As mentioned earlier, the existing membrane-making process has three disadvantages. One is to use a large amount of n-hexane (≥64.6%) to dissolve PDMS, resulting in a large amount of organic waste gas in the membrane-making process. At the same time, the post-treatment of organic waste gas is further Increased production costs. The second is that due to the flammable and explosive properties of n-hexane, it needs to be dried naturally to volatilize n-hexane, resulting in the curing and drying time of the composite film being much longer than the allowed time of continuous production equipment. The third is that the water content in the casting liquid system is large and the polymer content is low, resulting in a long curing and drying time of the coating. For a long time, the above problems have become difficult technical problems in the art.

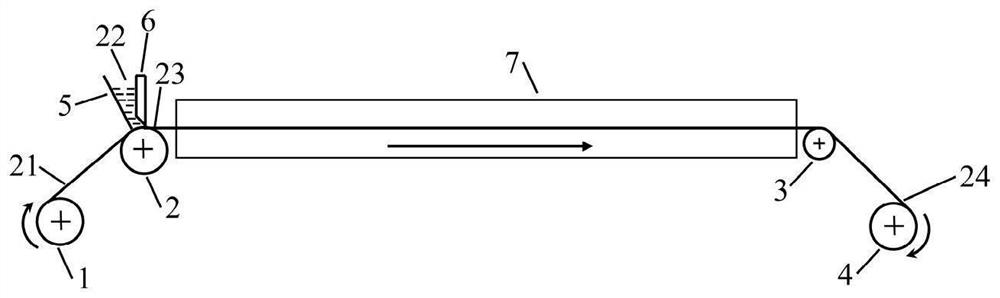

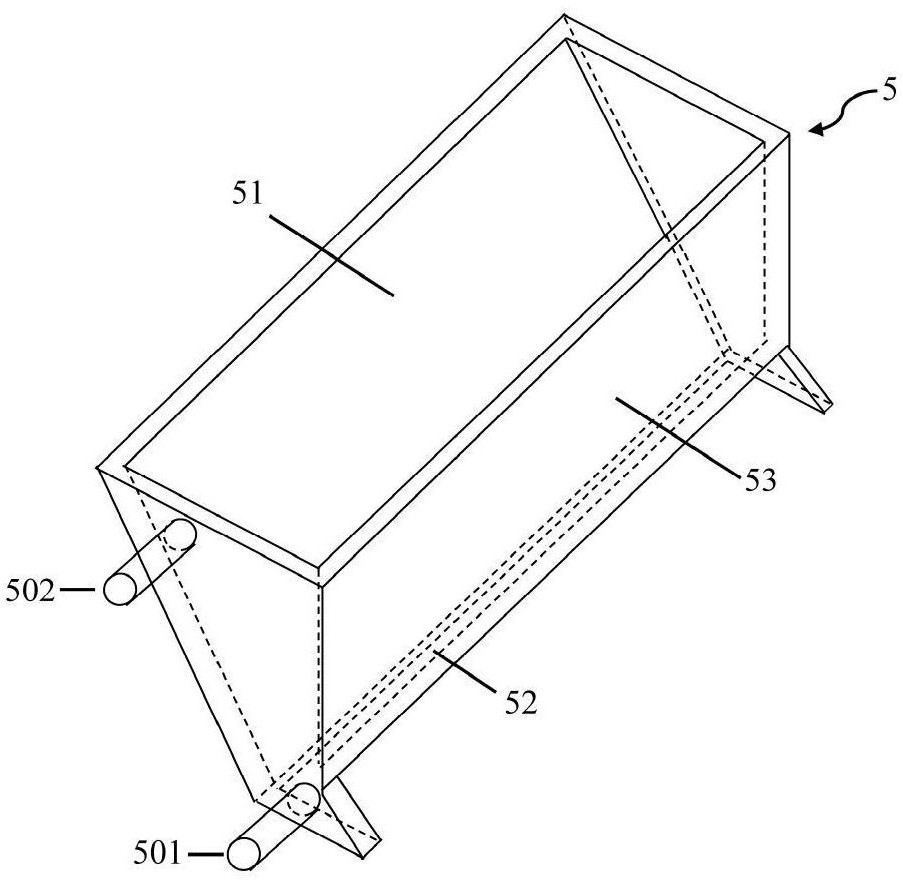

[0062] figure 1 It is a schematic diagram of a typical flat film continuous production device. Under the traction of the mot...

Embodiment 1

[0106] (1) The polytetrafluoroethylene ultrafiltration membrane is installed on the base film roll 1 as the base film 21, and one end of the base film 21 is pulled out to be wound on the scraping film roll 2 and the first winding roll 3 successively, and finally fixed On the second winding roller 4.

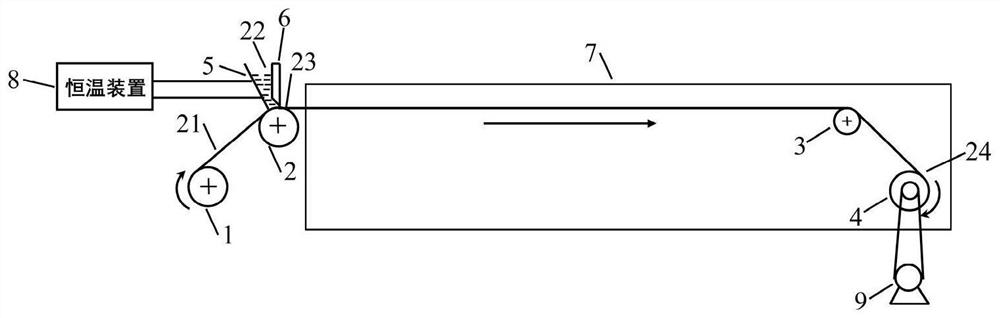

[0107] (2) Adjust the distance between the scraper 6 and the base film 21 to 40 μm, and the width of the base film 21 is 60 cm; start the thermostatic device 8 to keep the temperature of the casting solution tank 5 and the scraper 6 constant at 1° C.; 7. The internal temperature is controlled at 90°C.

[0108] (3) Mix 600g of hydroxyl-terminated polydimethylsiloxane with a viscosity of 10Pa·s, 120g of ethyl orthosilicate and 80g of water at 1°C, and stir mechanically at 800rpm for 1h; add 20g of dibutyltin dilaurate , stirring at room temperature for 5 minutes; vacuum degassing for 5 minutes to obtain casting solution 22.

[0109] (4) pour the casting solution 22 into the casti...

Embodiment 2

[0113] (1) The polytetrafluoroethylene ultrafiltration membrane is installed on the base film roll 1 as the base film 21, and one end of the base film 21 is pulled out to be wound on the scraping film roll 2 and the first winding roll 3 successively, and finally fixed On the second winding roller 4.

[0114] (2) Adjust the distance between the scraper 6 and the base film 21 to 40 μm, and the width of the base film 21 is 60 cm; start the thermostatic device 8 to keep the temperature of the casting solution tank 5 and the scraper 6 constant at 1° C.; 7. The internal temperature is controlled at 80°C.

[0115] (3) 600g of hydroxyl-terminated polydimethylsiloxane with a viscosity of 10Pa·s, 120g of tetraethyl orthosilicate and 80g of 3wt% dodecylbenzenesulfonic acid aqueous solution were mixed at 1°C, and the mixture was mixed at 800rpm Stir mechanically for 1 hour; add 20 g of dibutyltin dilaurate, stir at room temperature for 5 minutes; vacuum defoam for 5 minutes to obtain cas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com