Preparation method for smolder distillers' grain soil for mushroom material and cow dung self-propagation mushroom material

A technology of mushroom material and shochu, which is applied in the field of cow dung self-breeding mushroom material, the preparation of smoked distiller's grain soil for mushroom material, and the cultivation of self-breeding mushrooms, which can solve the problems of cow manure pollution, economic added value, low utilization rate of straw, etc. , to achieve the effect of broadening the source of raw materials, increasing the degree of looseness and fertility, and increasing the emergence rate and growth speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

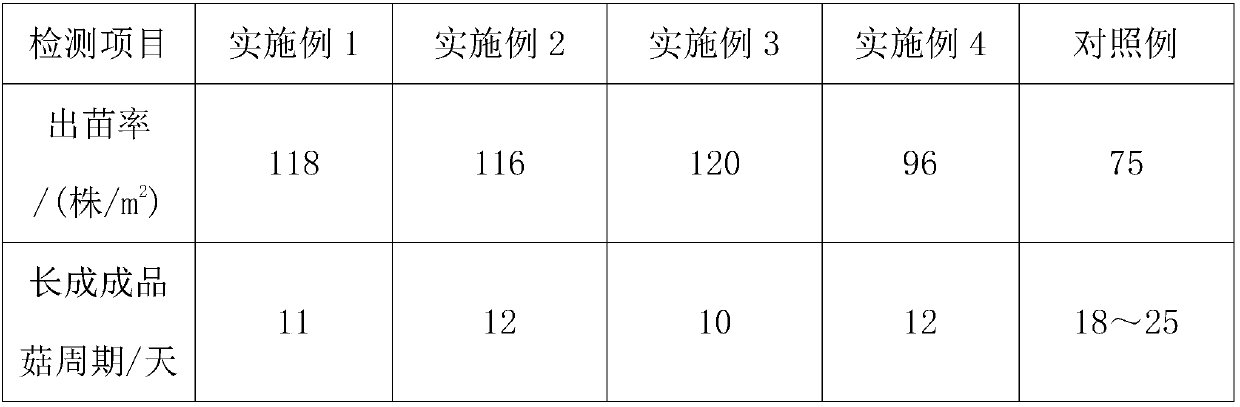

Embodiment 1

[0038] A method for planting self-propagating mushrooms, comprising the steps of: using cow dung self-propagating mushroom material to flatten a flat soil ridge with a width of 1 m and a thickness of 300 mm, the spacing between two adjacent flat soil ridges is 300 mm, and the flat soil ridge is flattened. The humidity is 20% and the temperature is 25℃; when the diameter of the mushroom umbrella head on the upper end of the mushroom reaches 50-60mm, it can be harvested;

[0039] The cow dung self-propagating mushroom material is composed of the following components by weight: 100 parts of fresh cow dung, 200 parts of smoked shochu lees soil for mushroom material, and 10 parts of straw material;

[0040] The preparation method of the smoked shochu lees soil for mushroom material comprises the following steps:

[0041] S1, 40 parts by weight of straw materials are obtained, and 200 parts by weight of the floating soil in the bamboo forest are taken to raise a ridge, the height of...

Embodiment 2

[0047] A method for planting self-propagating mushrooms, comprising the following steps: using cow dung self-propagating mushroom material to flatten a flat soil ridge with a width of 1.5 m and a thickness of 400 mm, the spacing between two adjacent flat soil ridges is 400 mm, and the flat soil ridge is 400 mm apart. The humidity of the ridge is 22% and the temperature is 28°C; the mushrooms can be harvested 7 days after the emergence of the mushrooms;

[0048] The cow dung self-propagating mushroom material is composed of the following components by weight: 110 parts of fresh cow dung, 250 parts of smoked shochu lees soil for mushroom material, and 12 parts of straw material;

[0049] The preparation method of the smoked shochu lees soil for mushroom material comprises the following steps:

[0050] S1, 50 parts by weight of straw materials are obtained, and 250 parts by weight of the floating soil in the bamboo forest are taken to raise a ridge, the height of the ridge is 400...

Embodiment 3

[0056] A method for planting self-propagating mushrooms, comprising the following steps: using cow dung self-propagating mushroom material to flatten a flat soil ridge with a width of 1.2 m and a thickness of 400 mm, the spacing between two adjacent flat soil ridges is 400 mm, and the flat soil ridges are flattened. The humidity of the ridge is 22% and the temperature is 28°C; when the diameter of the mushroom umbrella head on the upper end of the mushroom reaches 50-60mm, it can be harvested;

[0057] The cow dung self-propagating mushroom material is composed of the following components by weight: 100 parts of fresh cow dung, 250 parts of smoked shochu lees soil for mushroom material, and 12 parts of straw material;

[0058] The preparation method of the smoked shochu lees soil for mushroom material comprises the following steps:

[0059] S1, 50 parts by weight of straw materials are obtained, and 200 parts by weight of floating soil in the bamboo forest are taken to raise a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com