Oxygen flame composite plasma torch

A technology of plasma torch and oxygen flame, applied in the direction of plasma, electrical components, etc., can solve the problems of high cost, frequent replacement cycle and short service life of high-power arc equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

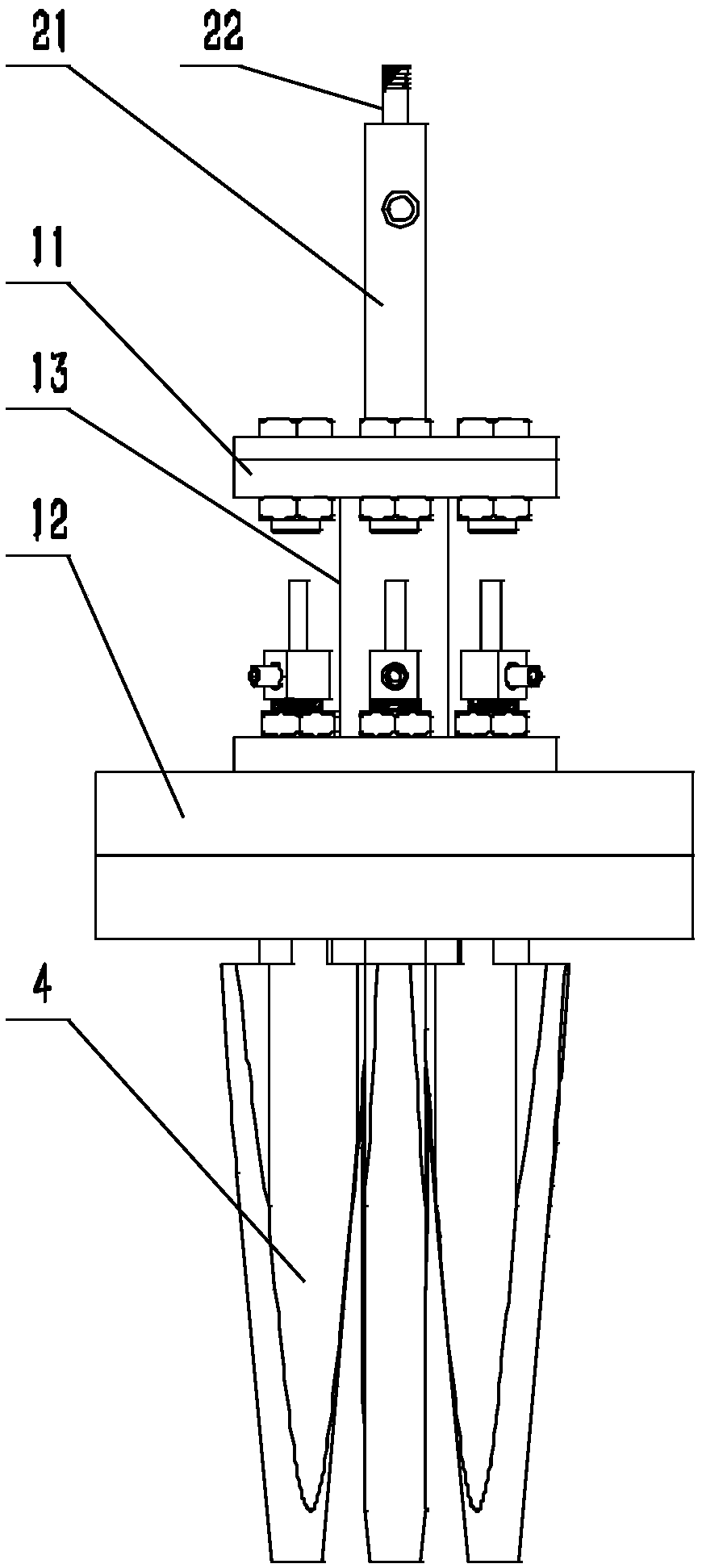

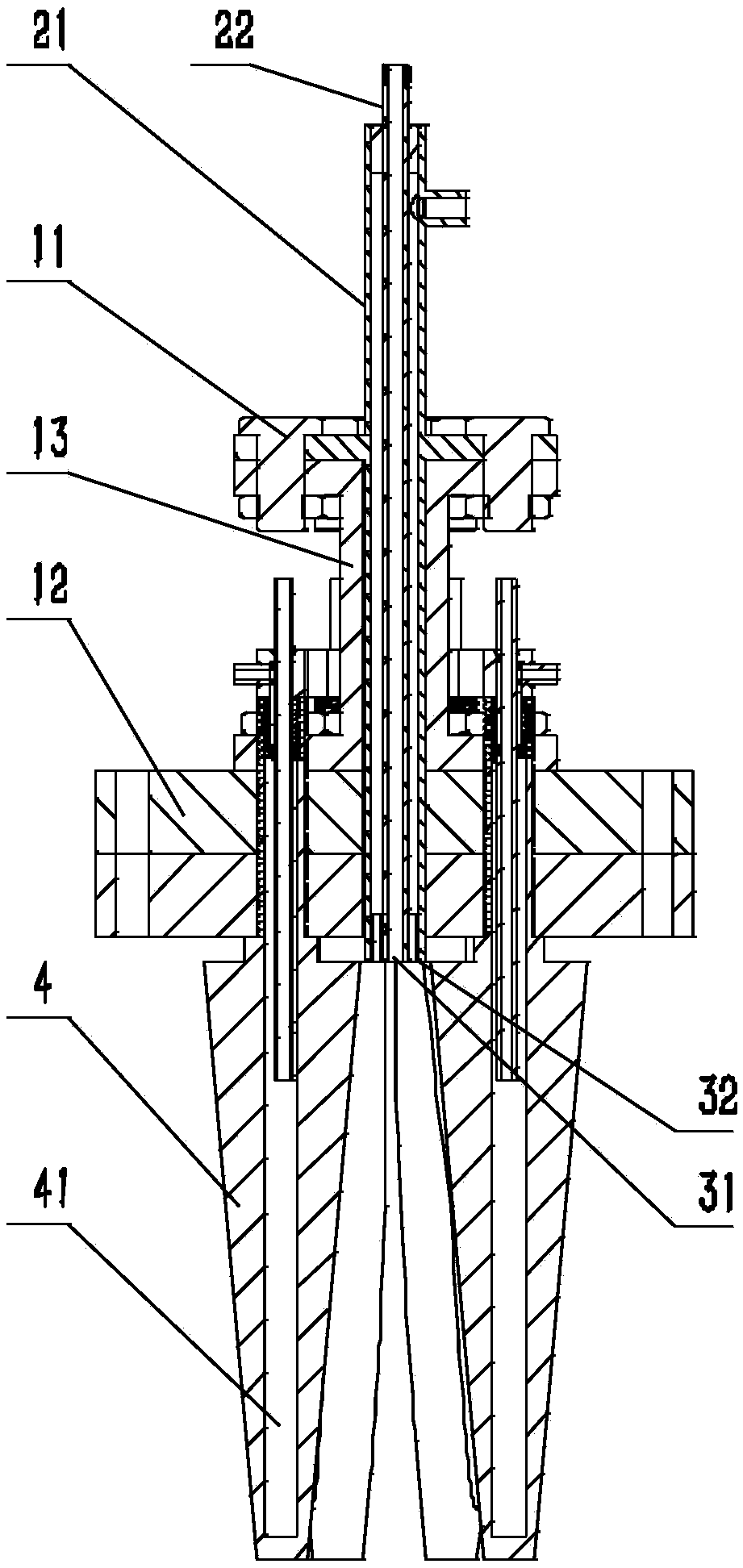

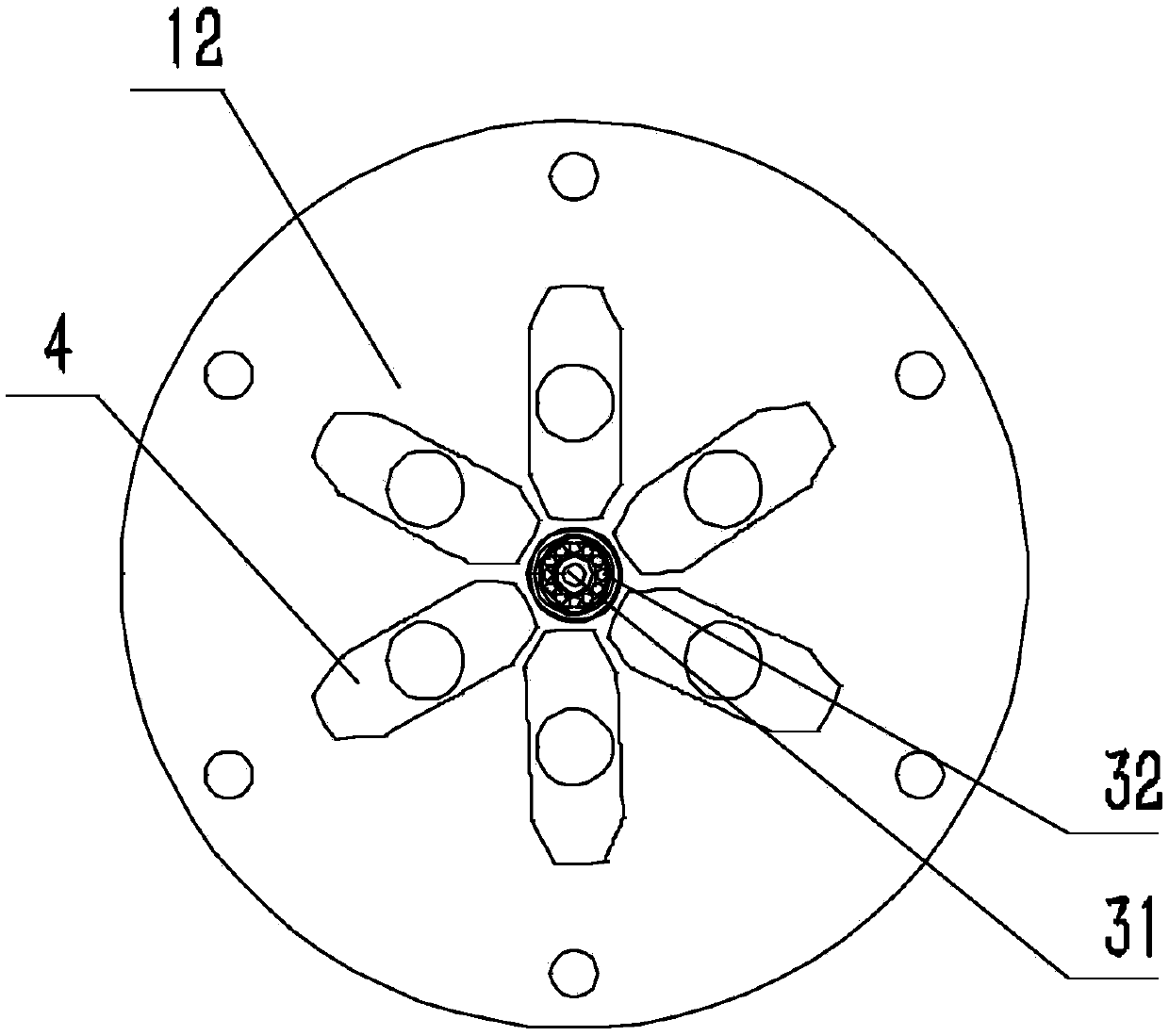

[0017] Such as Figures 1 to 3 as shown, figure 1 It is a structural schematic diagram of an oxygen-flame composite plasma torch proposed by the present invention, figure 2 It is a schematic cross-sectional structure diagram of an oxygen-flame composite plasma torch proposed by the present invention, image 3 It is a schematic view of the structure of an oxygen-flame composite plasma torch proposed by the present invention.

[0018] refer to Figures 1 to 3 , an oxygen-flame composite plasma torch proposed by the present invention, comprising: a mounting frame, an air inlet pipe, and an electrode assembly;

[0019] The mounting frame is provided with a first mounting flange 11 and a second mounting flange 12, and the middle part of the mounting frame is provided with a through hole extending from the first mounting flange 11 to the direction of the second mounting flange 12. An air inlet passage, the inlet end of which is located on the side of the first mounting flange 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com