A formwork erecting method of a shear wall formwork system

A formwork support method and shear wall technology, which are applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, can solve the problem that shear wall formwork is prone to explosion. Mold fixing effect and other issues, to achieve the effect of good rigidity, accurate position and size, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] The present invention discloses a formwork support method of a shear wall formwork system, comprising:

[0032] 1) According to the design requirements, the construction personnel releases the control line, releases the formwork control line at a distance of 200mm from the control line, and then releases the formwork positioning line according to the formwork control line, and needs to play the large-angle vertical control line at 100mm from the corner;

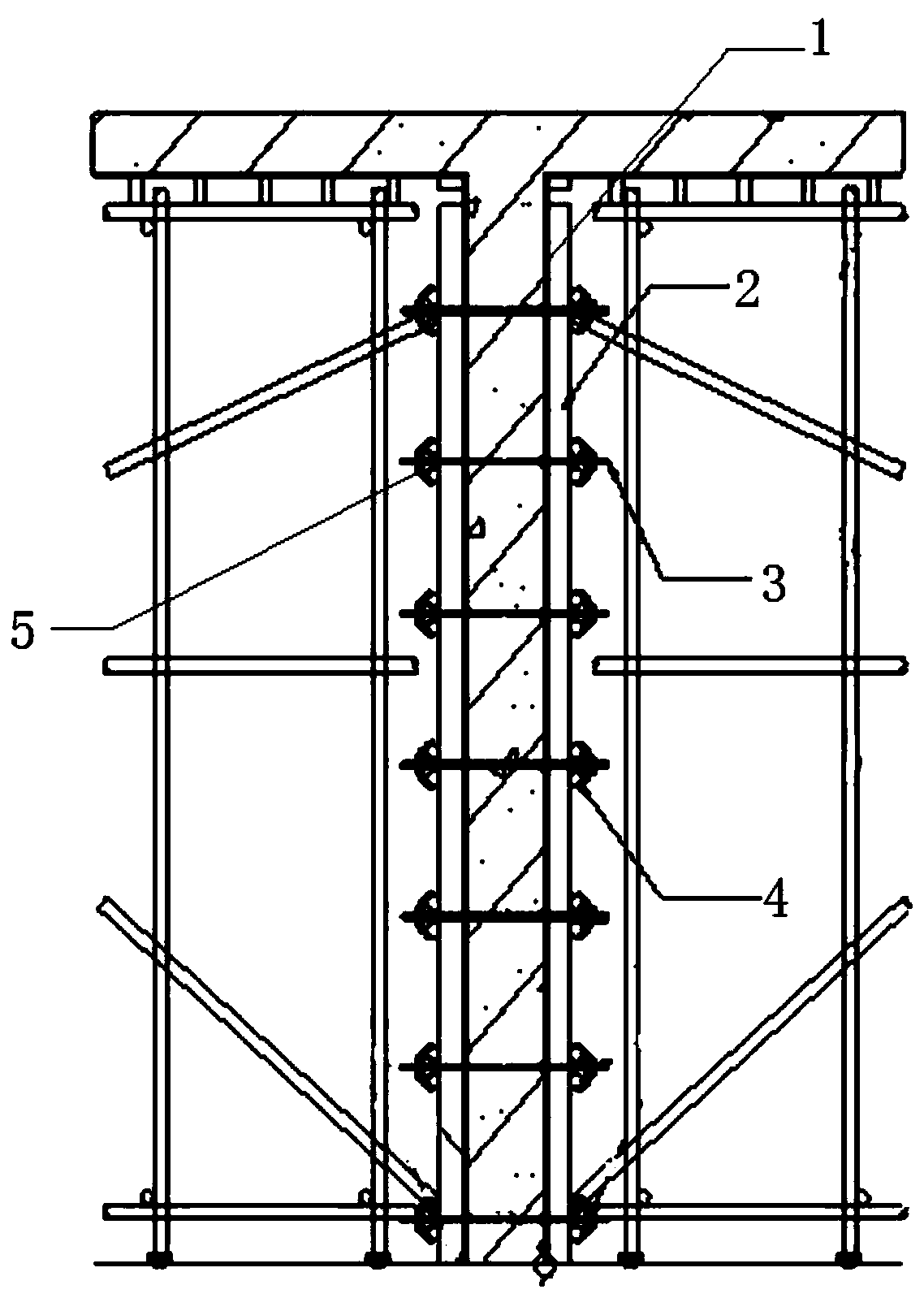

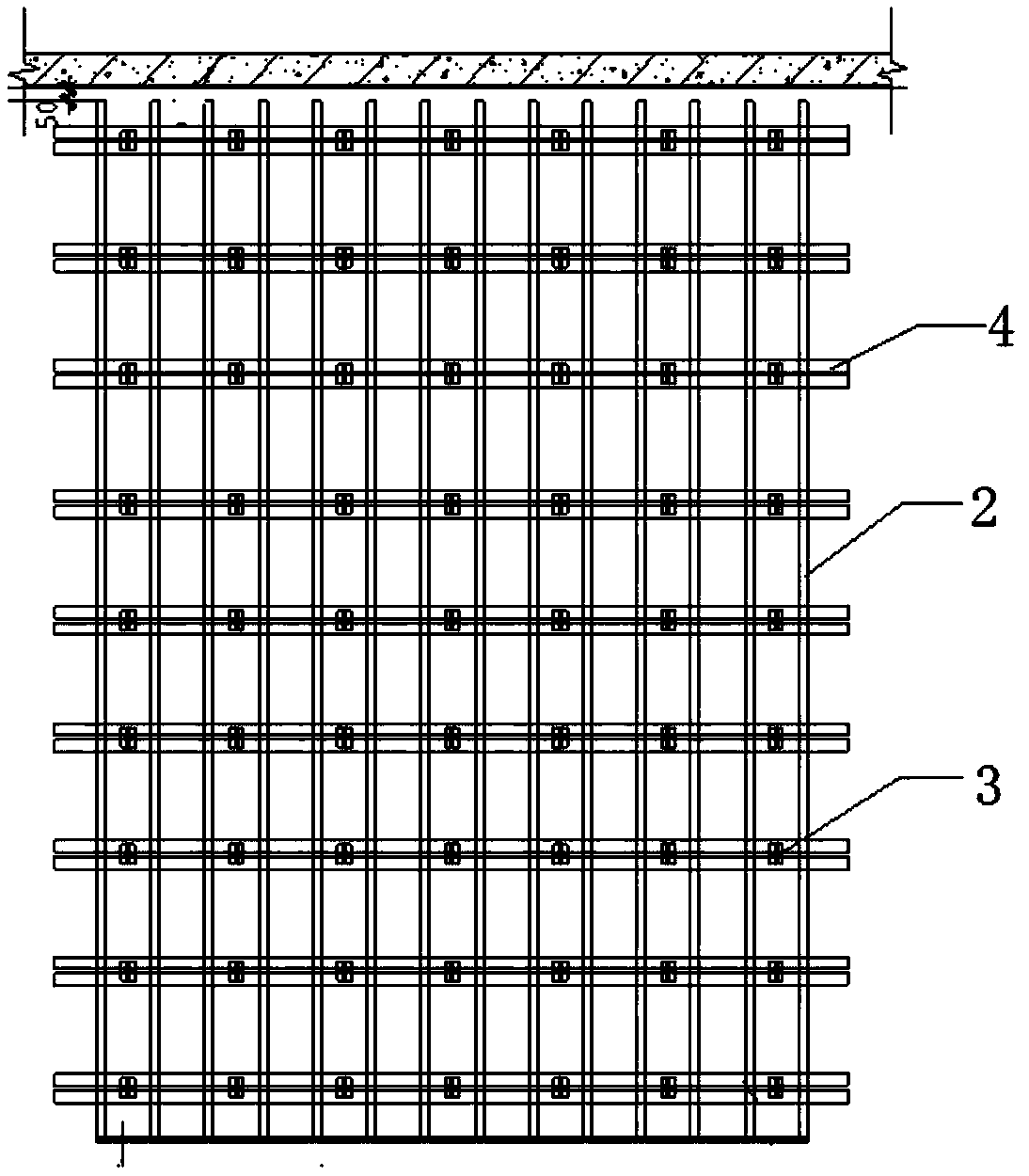

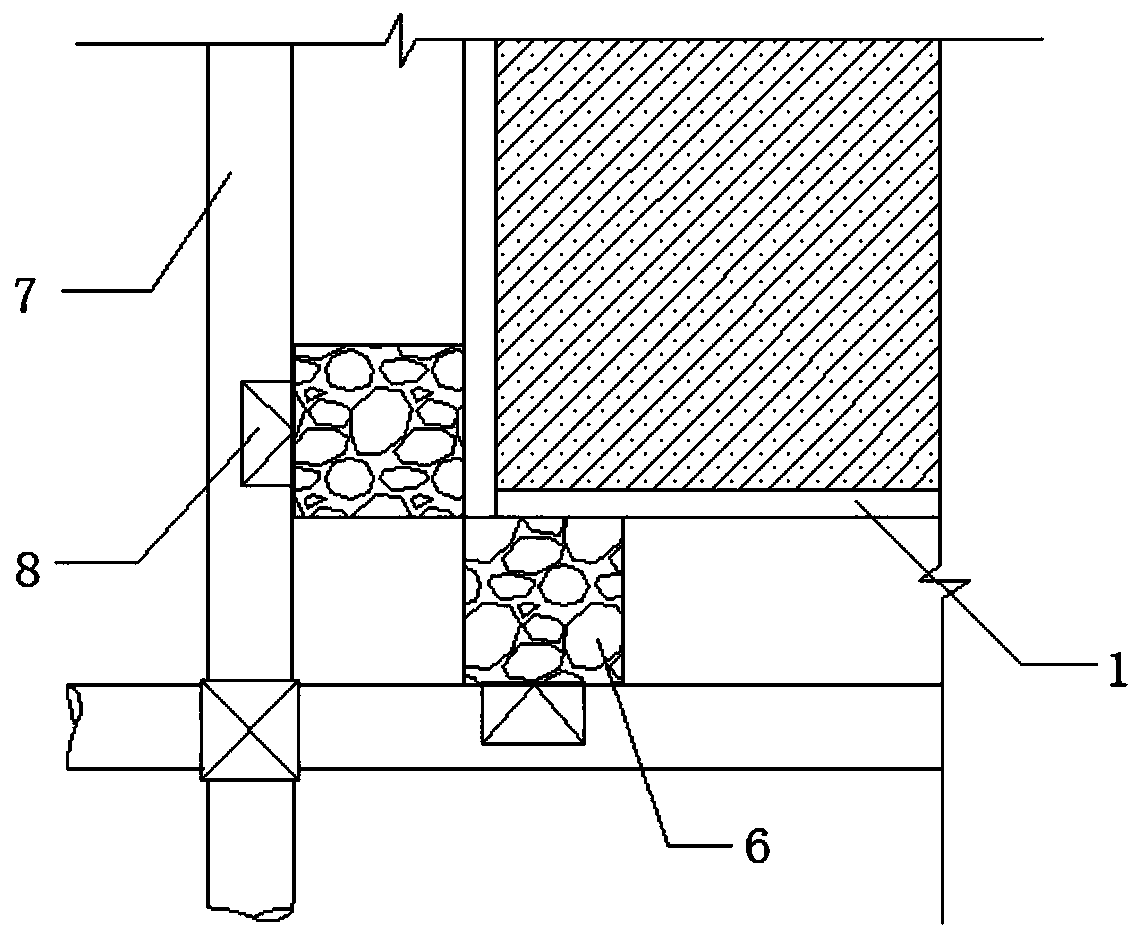

[0033] 2) if figure 1 with figure 2 As shown, the bamboo glue formwork 1 is arranged according to the released template positioning line, that is, a plurality of bamboo glue formworks 1 are arranged on the outer surface of the shear wall to be poured, and sponge strips are pasted between the joints of the bamboo glue formwork 1 and wooden Square compaction prevents grout from leakin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com