Reactive printing urea substitute and preparation method thereof

A technology of reactive printing and substitute agent, applied in dyeing, textile and papermaking, etc., can solve the problems of unsatisfactory hand feel uniformity, insufficient printing depth, neglecting fiber affinity, etc. Printing depth and uniformity, the effect of ensuring printing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029]In a more preferred embodiment, the preparation method of printing urea substitute of the present invention comprises:

[0030] Add aliphatic glycol ether carboxylate, polyoxyethylene ether carboxylate, and buffering agent to the modified clay in sequence, stir at a high speed of 800-1000rps for about 1 hour, and finally add deionized water to obtain active printing Urea substitute.

[0031] Compared with the prior art, the present invention has the following advantages and effects: high printing depth, high printing uniformity, and no need to add urea to the color paste.

Embodiment 1

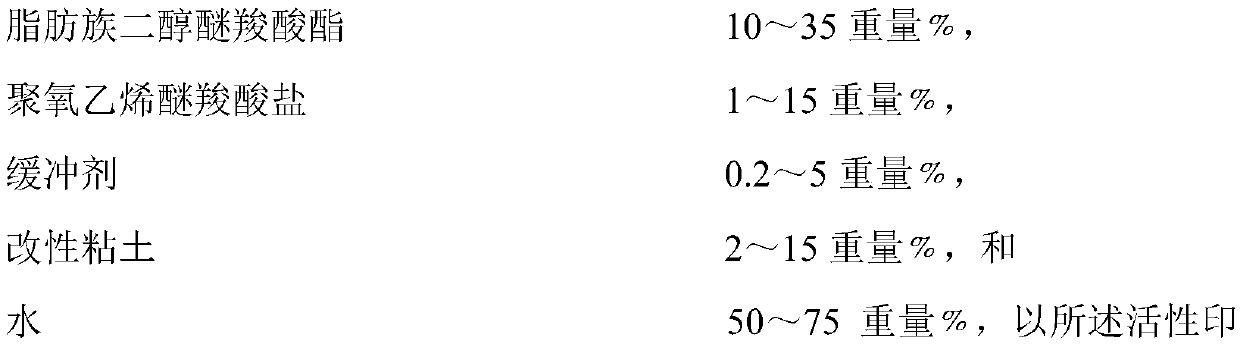

[0056] The formula that present embodiment adopts comprises following raw material:

[0057]

[0058] The active printing urea substitute of the present embodiment is prepared according to the following steps:

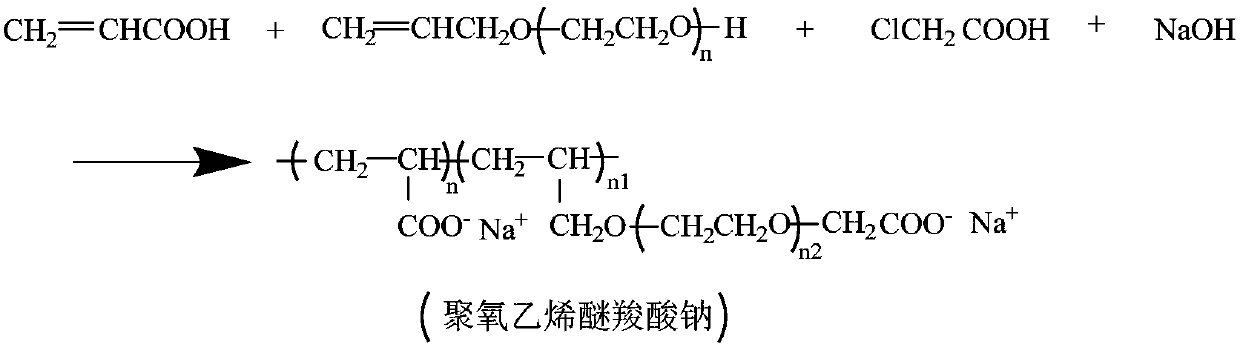

[0059] (1) The preparation method of cardanol polyoxyethylene ether sodium acetate (EO=7): 9 parts by weight of chloroacetic acid is dissolved in a sodium hydroxide solution of 50% by weight with 7 parts by weight of concentration, and then polymerized with 84 parts by weight of cardanol Mix oxyethylene ether alcohol (EO=7), heat up to 80°C, and keep it warm for 5 hours. Finally, recrystallize the product 3 times with absolute ethanol, filter with 1-3μm pore size filter paper, and distill under reduced pressure to remove ethanol and water to obtain Sodium cardanol oxyethylene ether acetate (EO=7), with a melting point of 10°C.

[0060] (2) The preparation method of modified clay 1: mix 0.5 parts by weight of acrylic acid with 22.5 parts by weight of allyl alcohol p...

Embodiment 2

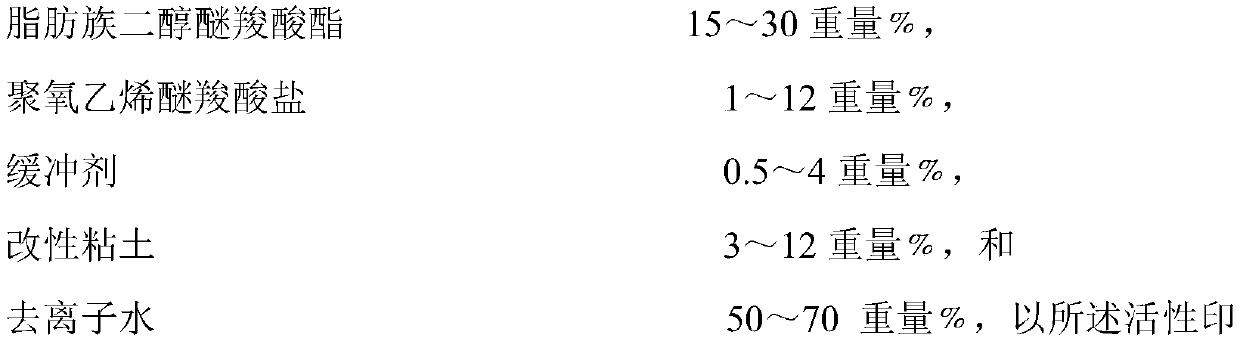

[0063] The formula that present embodiment adopts comprises following raw material:

[0064]

[0065] The active printing urea substitute of the present embodiment is prepared according to the following steps:

[0066] (1) The preparation method of fatty acid polyoxyethylene ester sodium acetate (EO=15): 8 parts by weight of chloroacetic acid are dissolved in 50 parts by weight of sodium hydroxide solution with 7 parts by weight of concentration, and then mixed with 85 parts by weight of octadecanoic acid Mix polyoxyethylene ether esters (EO=15), heat up to 80°C, and keep warm for 5 hours. Finally, recrystallize the product with absolute ethanol for 3 times, filter with 1-3μm pore size filter paper, and distill under reduced pressure to remove ethanol and water. Fatty acid polyoxyethylene sodium acetate (EO=15) was obtained with a melting point of 8°C.

[0067] (2) The preparation method of modified clay 2: mix 0.5 parts by weight of acrylic acid with 24.5 parts by weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com