Yarn distribution method of fiber layer connected fabric

A technology of fiber layer and fabric, which is applied in the field of yarn cloth of fiber layer and fabric, can solve the problems of small opening height, poor structure designability, low weaving efficiency, etc., and achieve high weaving efficiency, low cost and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

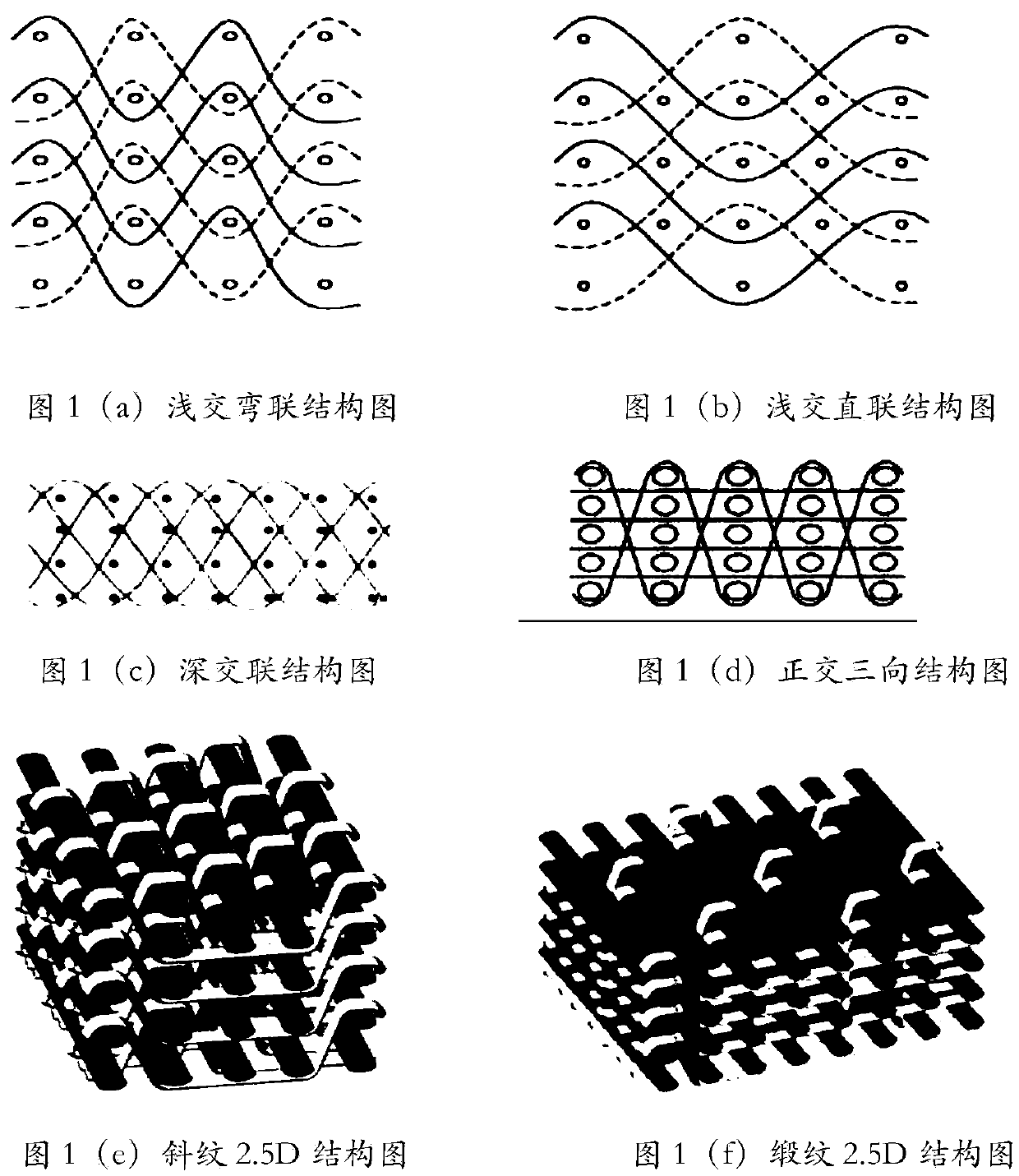

[0035] Embodiment 1: Using the automatic opening preparation method and device of the fiber layered three-dimensional fabric of the present invention to weave a plate-shaped fabric. The fabric size is 100 mm in length, 20 mm in width, and 2.0 mm in thickness.

[0036] The process design is as follows: the fiber adopts 190Tex quartz fiber; the fabric structure is shallow cross-bending; 2 warp yarns, 4 weft yarns; 4 layers of warp yarns, 16 rows of warp yarns; the warp yarn density is 8.0 yarns / cm, and the weft yarn density is 2.0 yarns / cm; All warp yarns participate in weaving.

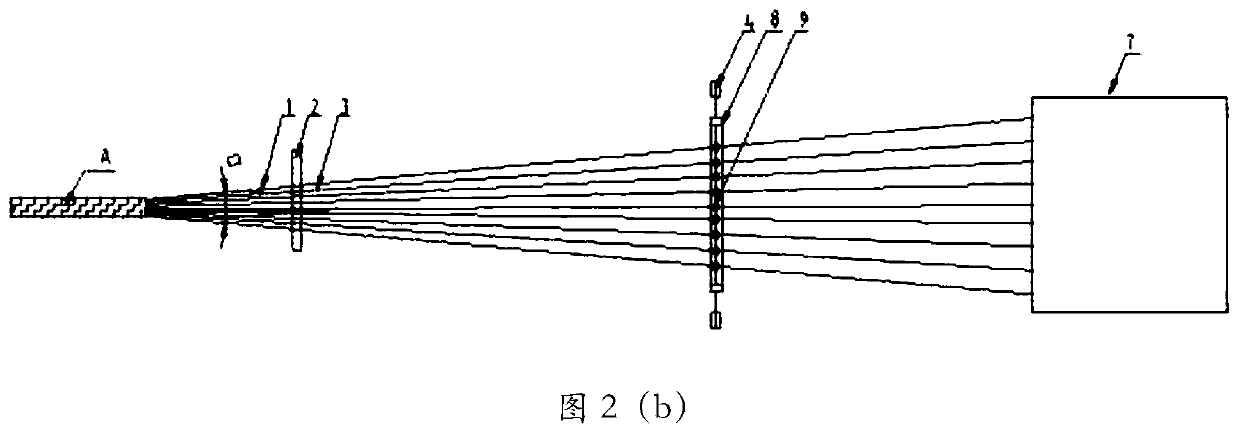

[0037] The specific process implementation steps are described as follows:

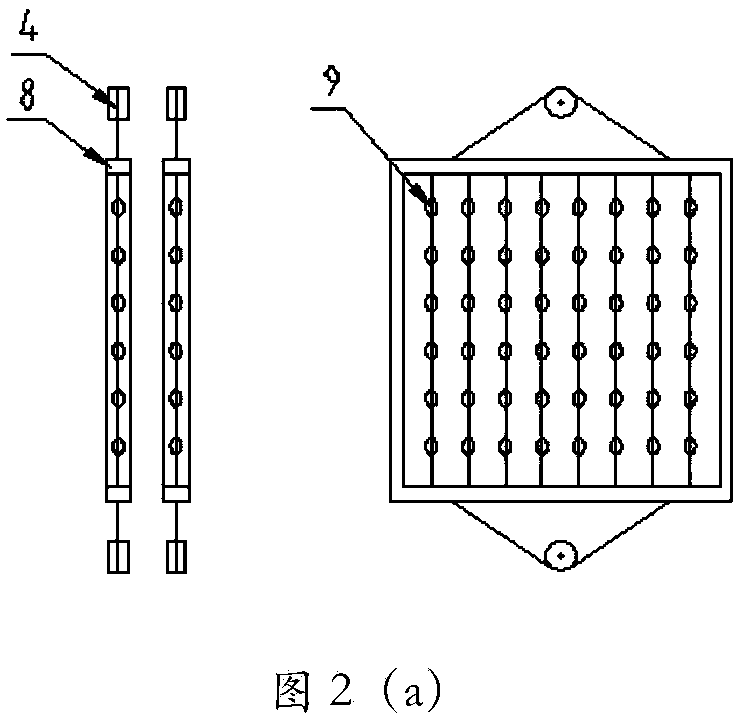

[0038] 1) passing the warp yarns in the warp let-off system sequentially through the heddles 14 as the warp yarns 10 in the first row of yarns;

[0039] 2) After step 1) is completed, the warp yarns in the let-off system are sequentially passed through the heddles 15 as the warp yarns 11 in the first row of yarns;

[0040] ...

Embodiment 2

[0046] Embodiment 2: Fabrics with special-shaped cross-sections Take fabrics with I-shaped cross-sections as an example. The I-shaped fabric is woven by using the automatic opening preparation method and device of the fiber layered three-dimensional fabric of the present invention. The size of the fabric is 100mm in length, H-shaped section height H=30mm, width B=30mm, and wall thickness δ=10.0mm.

[0047] The process design is as follows: the fiber is made of 12K carbon fiber; the fabric structure is orthogonal three-way; 2 1 strand, 1 strand of normal yarn; cloth yarn is 24 rows, 21 layers; participate in weaving warp yarn 14 layers (21 layers of middle ribs), 24 rows of warp yarns (8 rows of middle ribs); warp yarn density is 8.0 threads / cm, weft yarn density is 4.0 roots / cm.

[0048] The specific process implementation steps are described as follows:

[0049] 1) if Figure 5As shown, the warp yarns in the let-off system are sequentially passed through the heddles 14 as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com