Electrochemical polishing device for teaching

A polishing device and chemical polishing technology, applied in the field of metal surface treatment, can solve the problems of high safety protection requirements, complex structure, complex device structure, etc., and achieve the effect of good polishing effect, low roughness and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

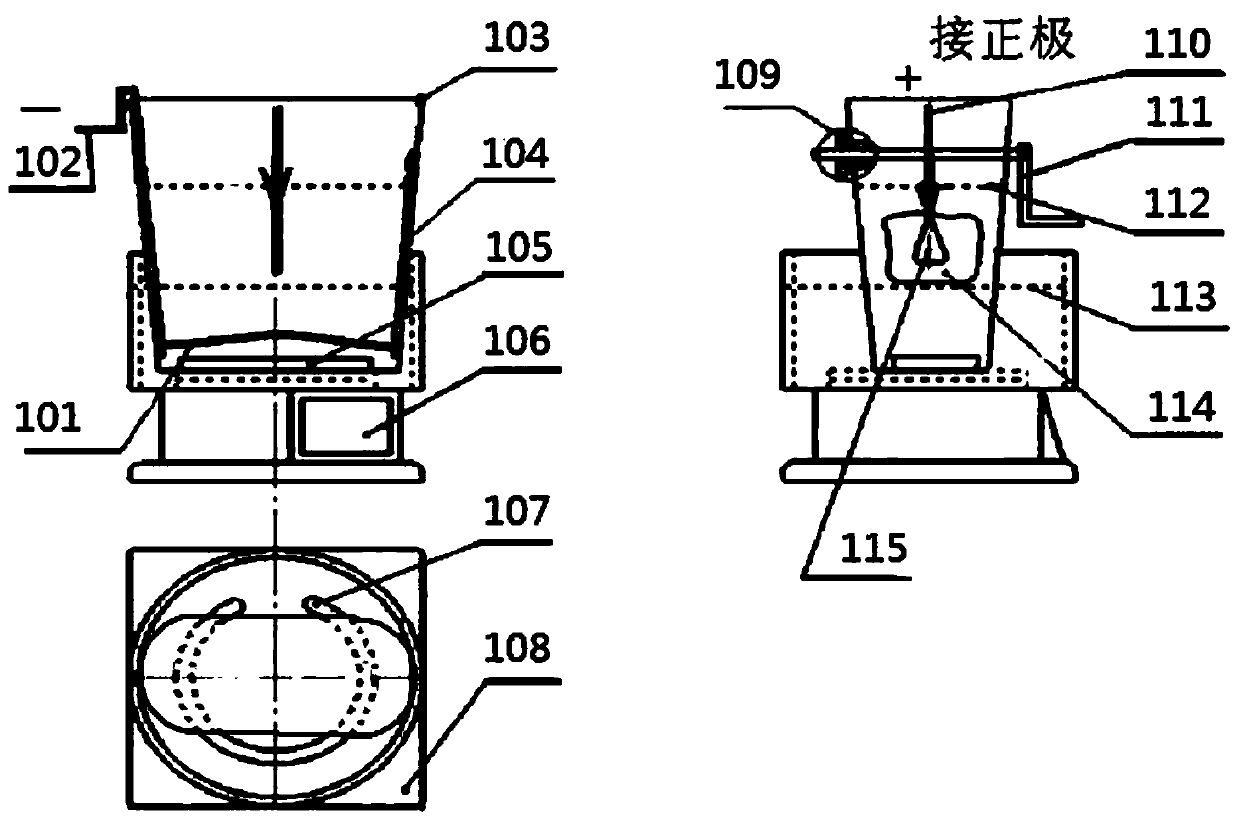

[0030] Such as figure 1 , figure 2 , image 3 As shown, a teaching electrochemical polishing device includes a DC electrochemical polishing power supply 7 , a constant temperature water bath 108 , an electrolyte polishing tank 103 , and a hanger 111 for polishing parts.

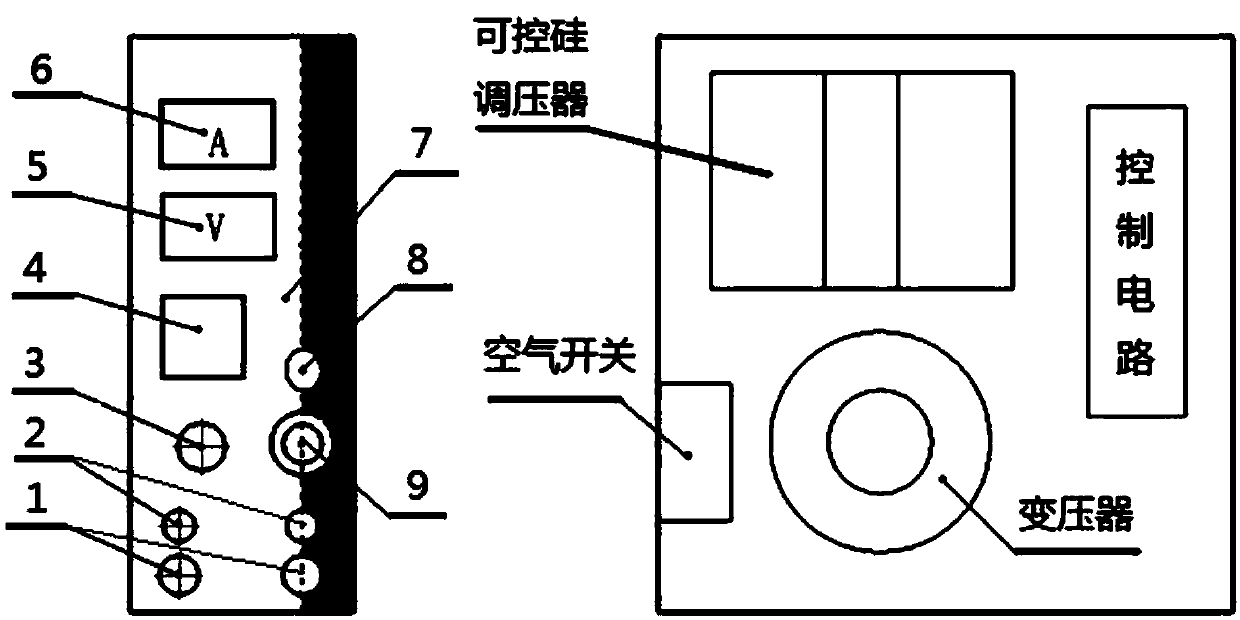

[0031] An air switch, a thyristor voltage regulator, a transformer, and a control circuit board are installed inside the electrochemical DC power supply, and the external control panel includes a voltage regulator 3, an ammeter 6, a voltmeter 5, a timer 4, and an output power polarity converter 8. Reset button RESET9, output terminal 1, indicator light 2. The electrochemical DC power supply can convert 220V single-phase AC power into electrochemical polishing DC output, and the polishing voltage can be set by rotating the voltage regulator knob. The polishing voltage and polishing current are displayed in real time on the ammeter 6 and voltmeter 5 on the front of the power panel.

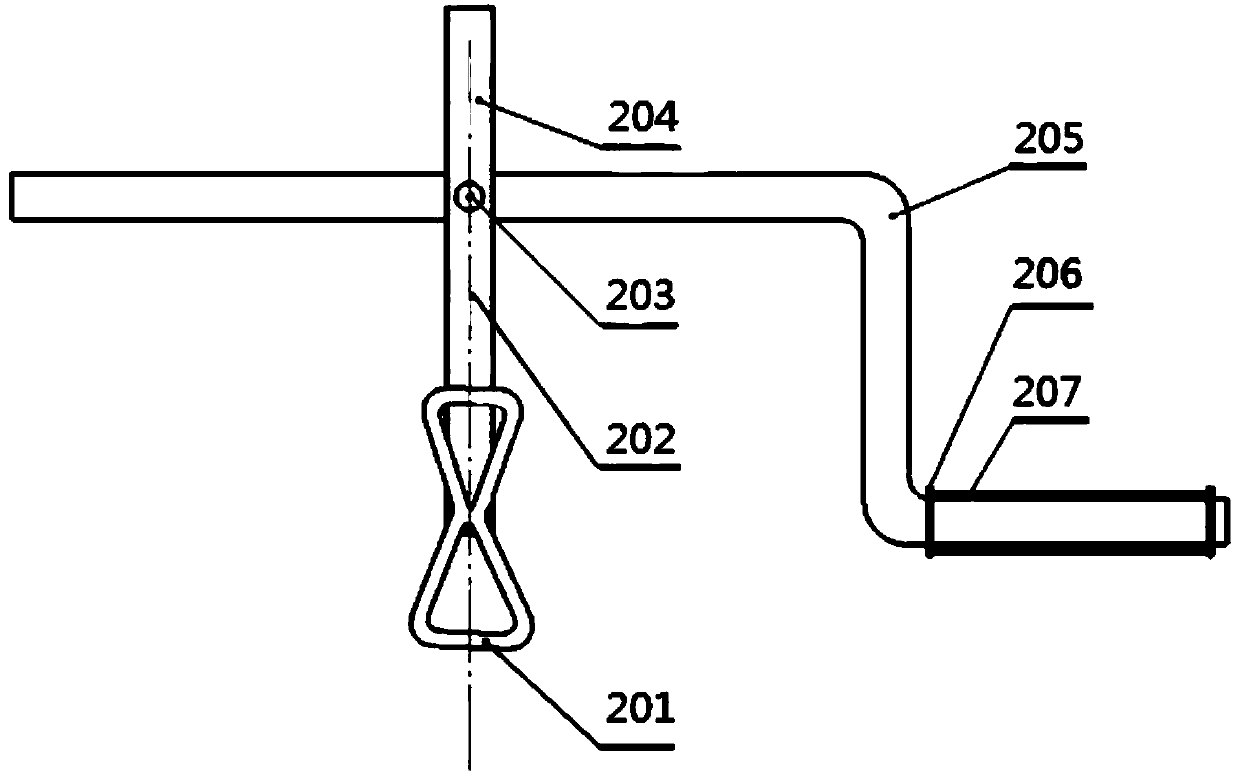

[0032] The polishing st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com