Discharge mechanism for candy wrapping

A packaging and unloading technology, which is applied in the field of unloading mechanism for candy packaging, can solve the problems of insufficient compact structure, single function, incompetence for high efficiency, etc., and achieve the effect of compact structure and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

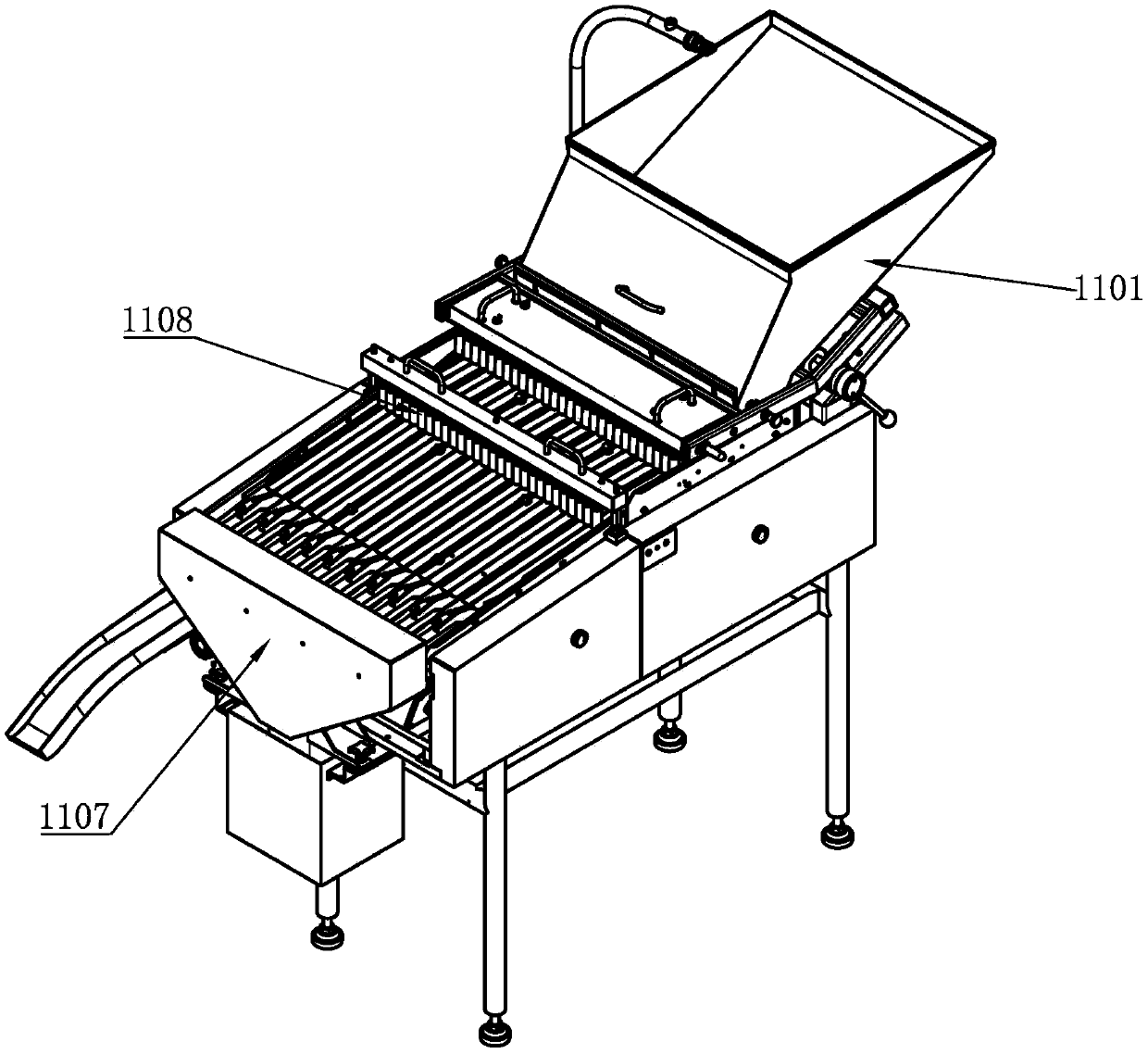

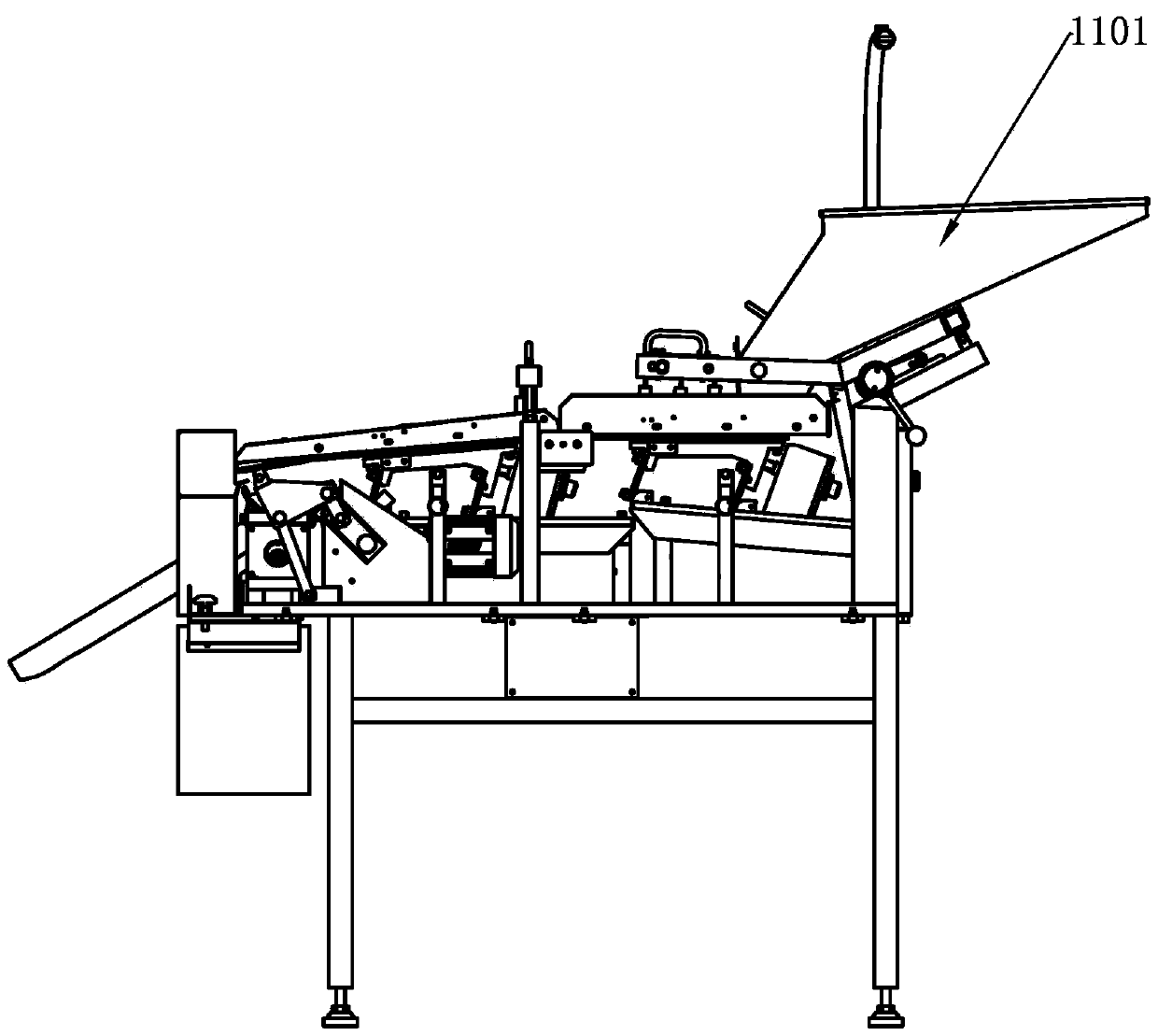

[0018] like Figure 1-5 As shown, the unloading mechanism for candy packaging of the present invention includes a frame, a silo 1101, several groups of vibrating assemblies 1108, a material receiving assembly, a material shifting assembly, a waste bin 1107, a current limiting assembly, and several groups of vibrating assemblies 1108 Installed on the frame from left to right in turn, the material bin 1101 is installed on one end of the frame, above the vibrating assembly 1108, the material receiving assembly and the feeding assembly are installed on the other end of the frame, below the end of the vibrating assembly 1108, and the waste bin 1107 is installed at the end of the frame, and the current limiting component is installed on the frame and above the vibrating component 1108;

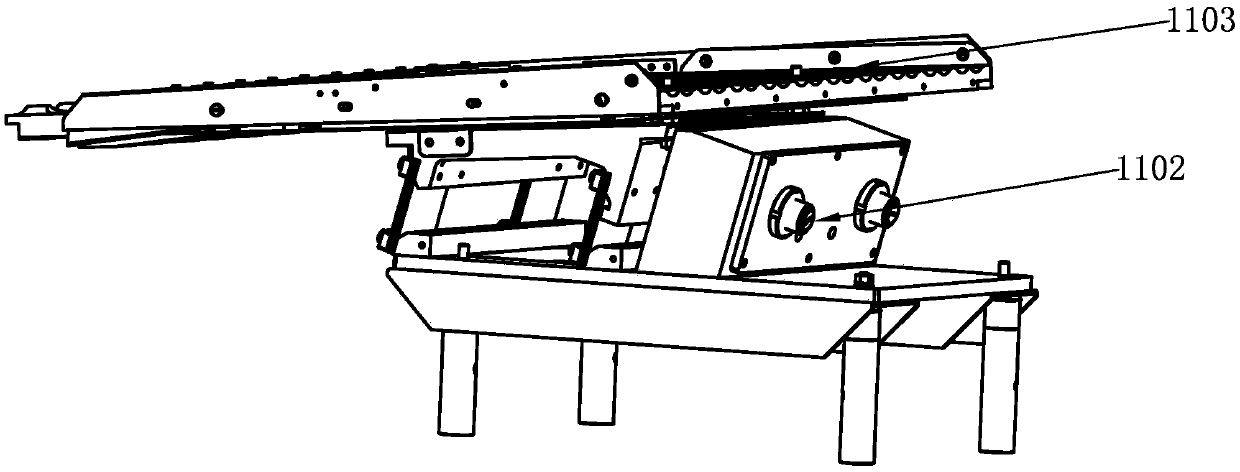

[0019] The vibrating assembly 1108 includes a vibrator one 1102 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com